Plasma processing apparatus capable of controlling plasma emission intensity

a plasma processing and plasma technology, applied in the direction of electrical apparatus, basic electric elements, electric discharge tubes, etc., can solve the problems of large amount of cost in order, complex operations, and the inability of conventional plasma processing apparatuses to be applied to semiconductor manufacturing apparatus used in mass production, etc., to achieve fine devices and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

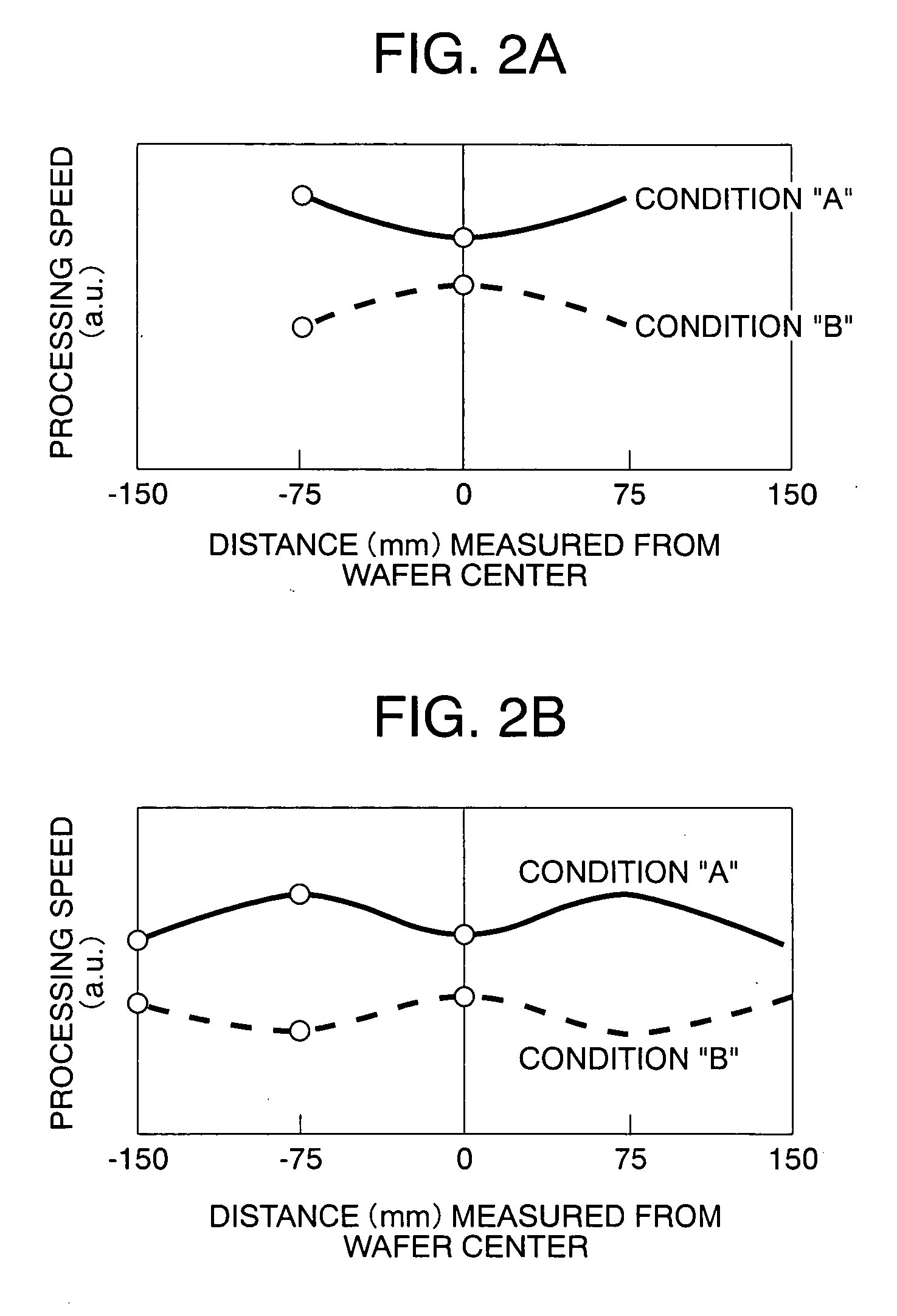

[0019] Referring now to drawings, best embodiment modes of the present invention will be described. FIG. 1 is a diagram for explaining a plasma processing apparatus according to an embodiment of the present invention. As represented in this drawing, a wafer mount-purpose stage 2, the temperature of which has been conditioned by a temperature conditioning apparatus 18, is provided inside a vacuum processing chamber 1 having a gas conducting unit 10, while the vacuum processing chamber 1 has been vacuum-exhausted, and a substantially circular shaped antenna electrode 7 is provided on a plane which is located opposite to this wafer mount-purpose stage 2, and the antenna electrode 7 is positioned parallel to the stage 2. High frequency power is supplied by a first high frequency power supply 11 via a first matching device 12 to the antenna electrode 7, and then plasma is generated by way of a mutual reaction between electromagnetic waves radiated from the antenna electrode 7 and magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequencies | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com