Tug barge lightering connection system

a connection system and tug boat technology, applied in waterborne vessels, towing/pushing equipment, vessel construction, etc., can solve the problems of tug boat sinking into the water, barge sitting lower in the water, and substantial waves, so as to maximize the relative movement efficiency and minimize the loss of secure connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

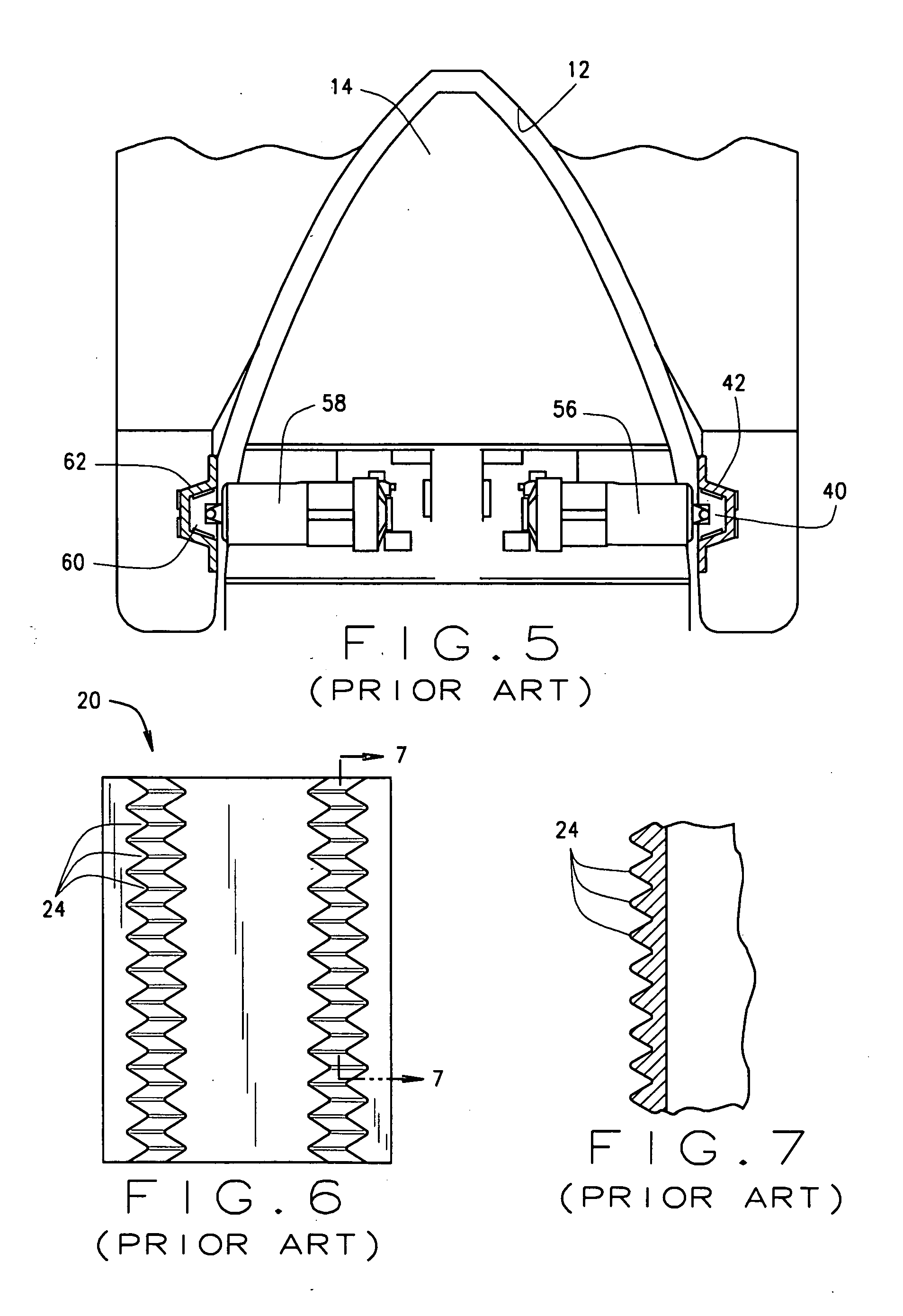

[0039] Referring now to the drawings in more detail, FIG. 8 generally shows the waveform surface of the present invention. Unlike the tooth-like projections of the prior-art coupling systems, waveform surface 30 is comprised of rounded projections 31. This permits an opposing surface of similar configuration to move smoothly over the projections. Angular, non-rounded edges are avoided. The waveform surface should have consistent amplitude and pitch dimensions, amplitude (A) being defined herein as the height of the wave crests, and pitch (P) being defined as the distance between wave crests as shown in FIG. 8. The optimum amplitude may vary depending on the weight load involved in the lightering operation, but frictional forces and compressive forces provided by the tug boat rams will play a significant role as well. In any event, the amplitude must be a value greater than zero, but have a value less than the pitch. Preferably, the ratio of the amplitude to pitch should be about 1:7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com