Tabbed transfer fins for air-cooled heat exchanger

a technology of heat exchangers and transfer fins, which is applied in the field of heat exchangers to achieve the effects of increasing pressure drop, facilitating uniform flow, and enhancing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

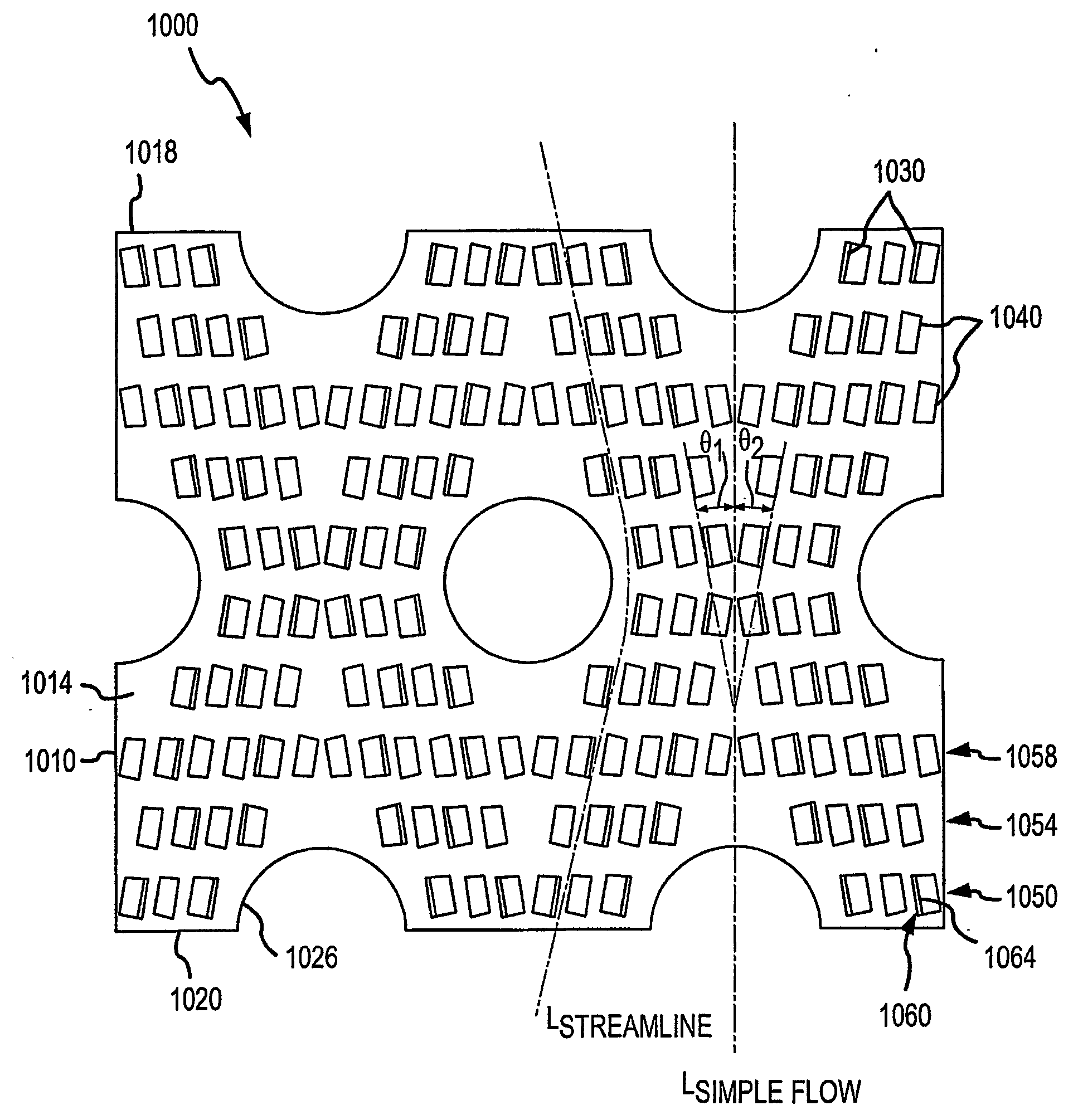

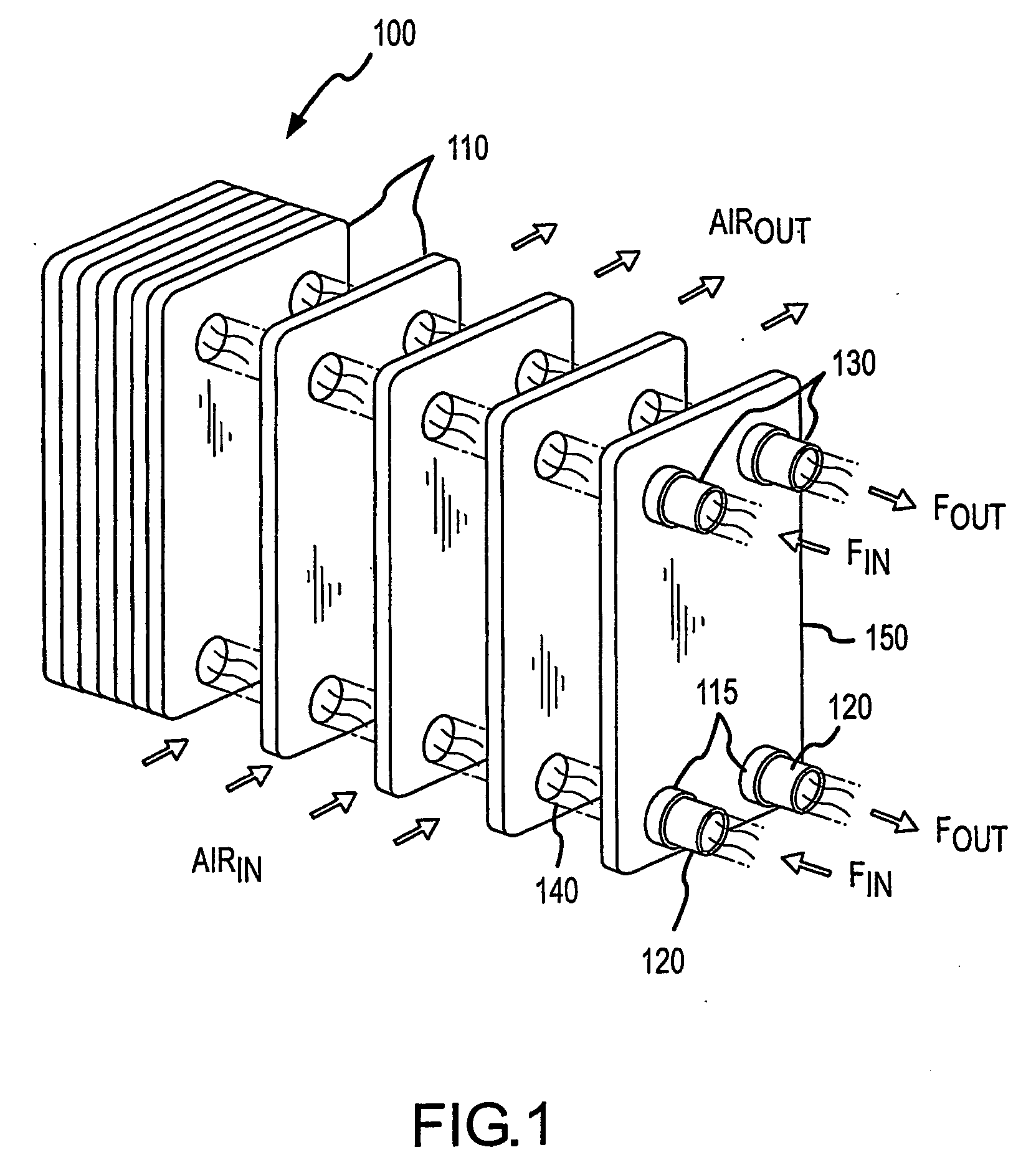

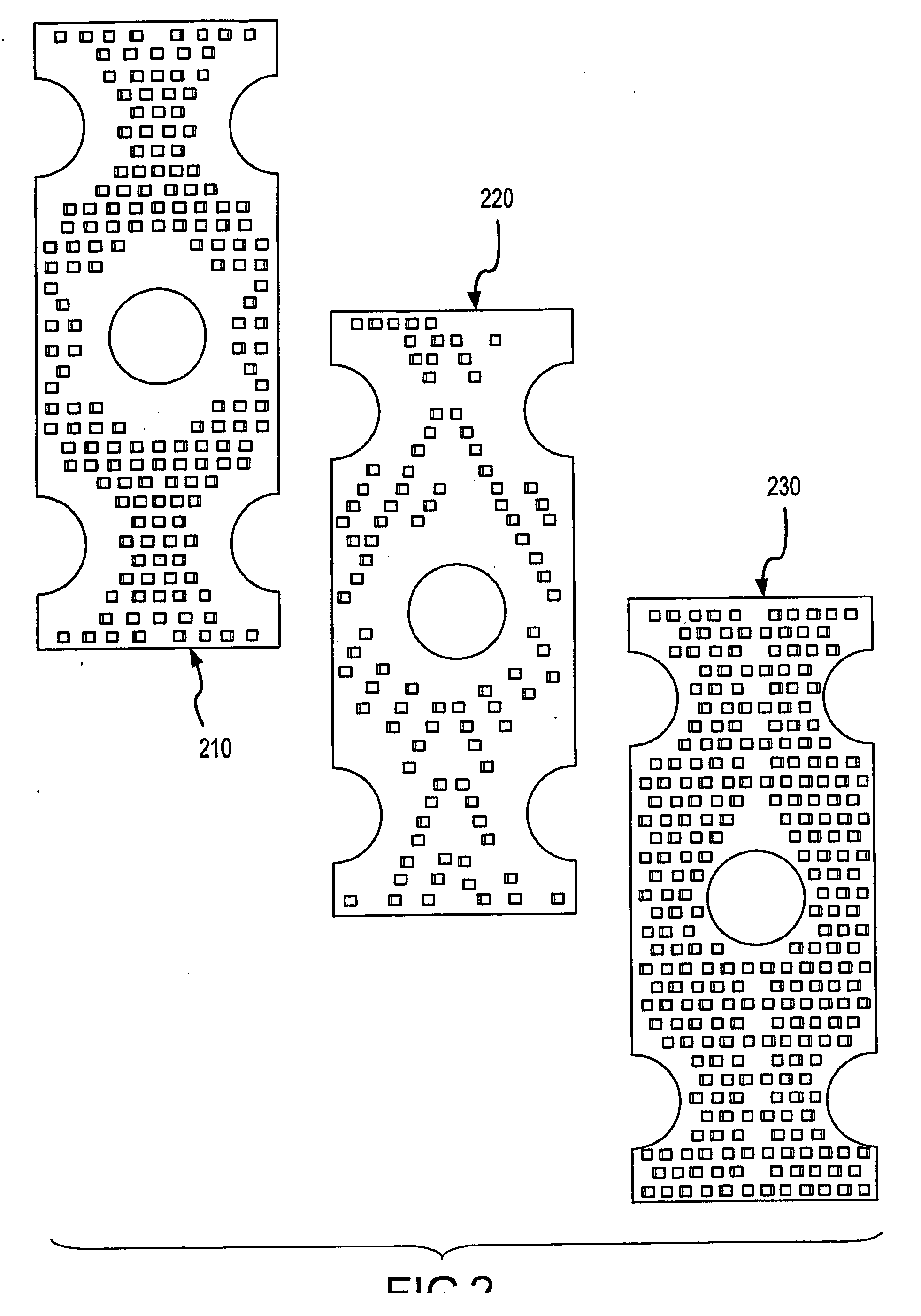

[0036] The present invention is directed to heat exchanger fins employing tabs to increase heat transfer effectiveness, heat exchangers or condensers incorporating such tabbed fins or plates such as air-cooled, finned-tube heat exchangers, and methods of making tabbed fins. Generally, each fin of the invention includes a multiplicity of small tabs or secondary fins that are formed by punching material (i.e., metal) out of the main fin body (i.e., creating a hole or opening) and the punched material is bent outward away from the main fin body in one or both directions from the surface of the fin. To minimize or control the creation of a vortex or increased pressure drop, the tabs are generally planar and aligned with the direction of the fluid, e.g., air, flowing over the fins in the channel between adjacent fins. In other words, a leading edge of the tab first contacts the flowing gas and the substantially planar body of the tab is aligned substantially parallel to the gas flow path...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| bend angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com