Message management facility for an industrial process control environment

a technology of message management and industrial process control, applied in the direction of program control, data switching network, instruments, etc., can solve the problems of heavy workload on controllers, complex industrial processes, and large volumes of information that human beings cannot digest, and achieve the effect of facilitating the execution of a variety of functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

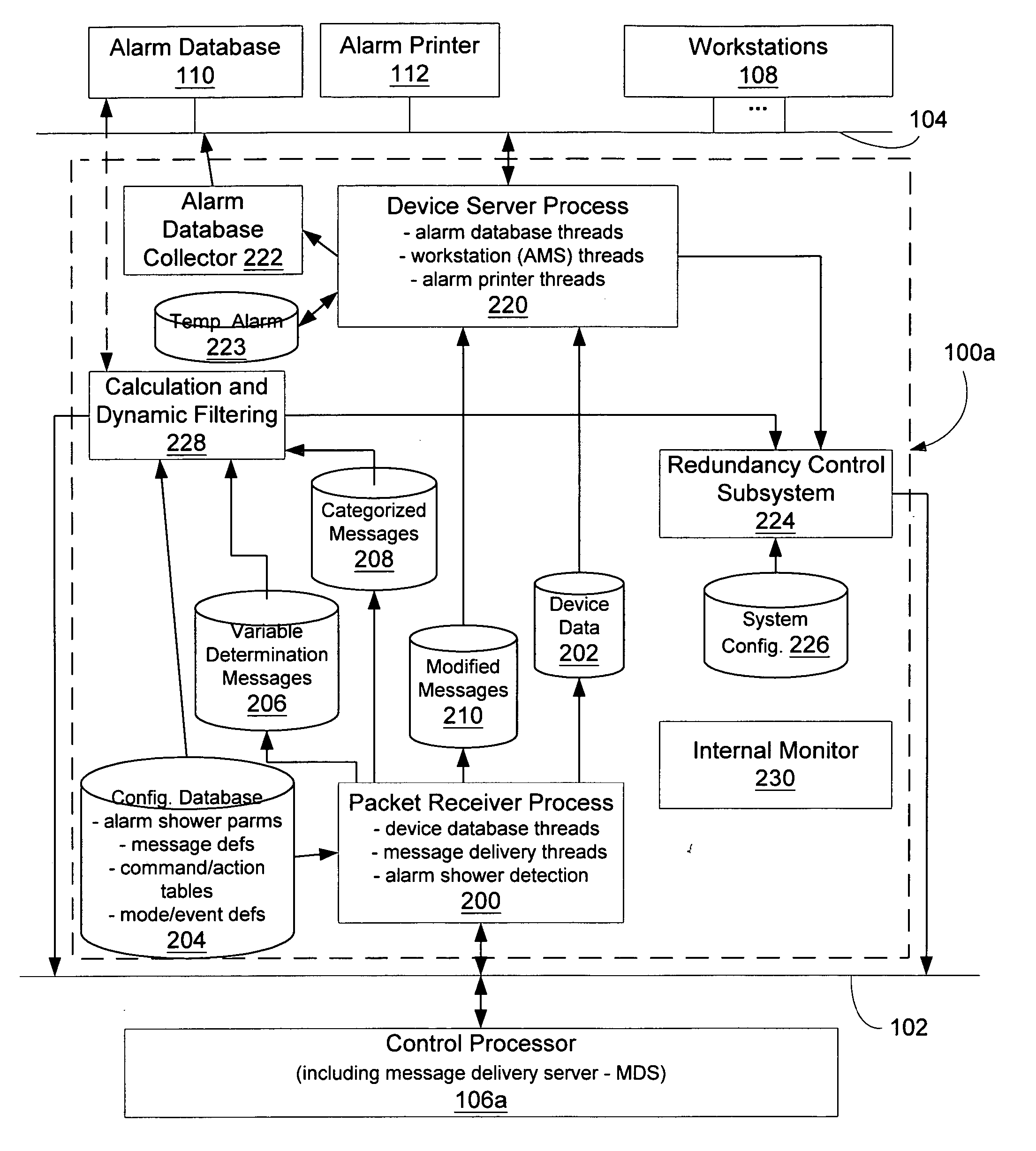

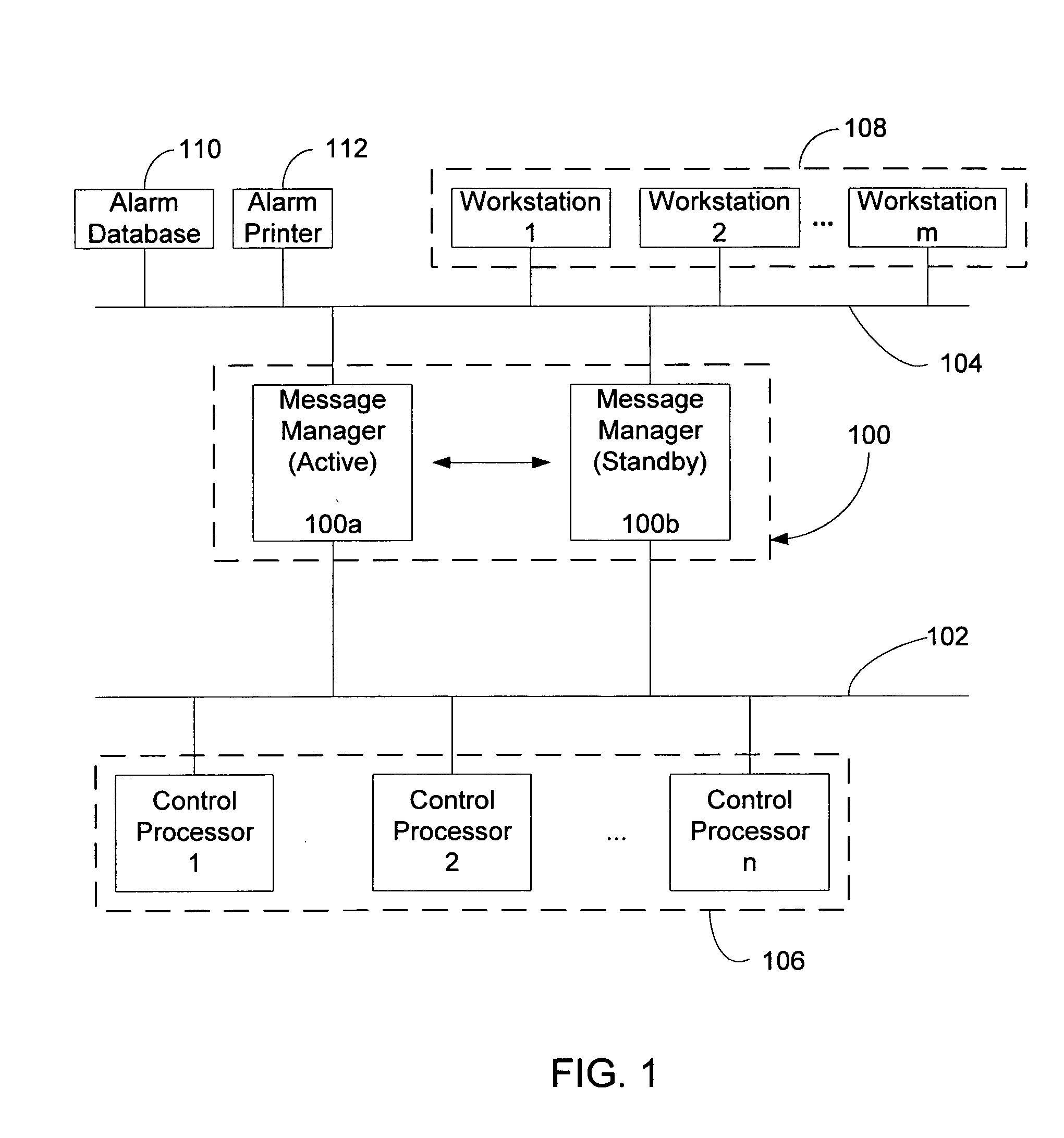

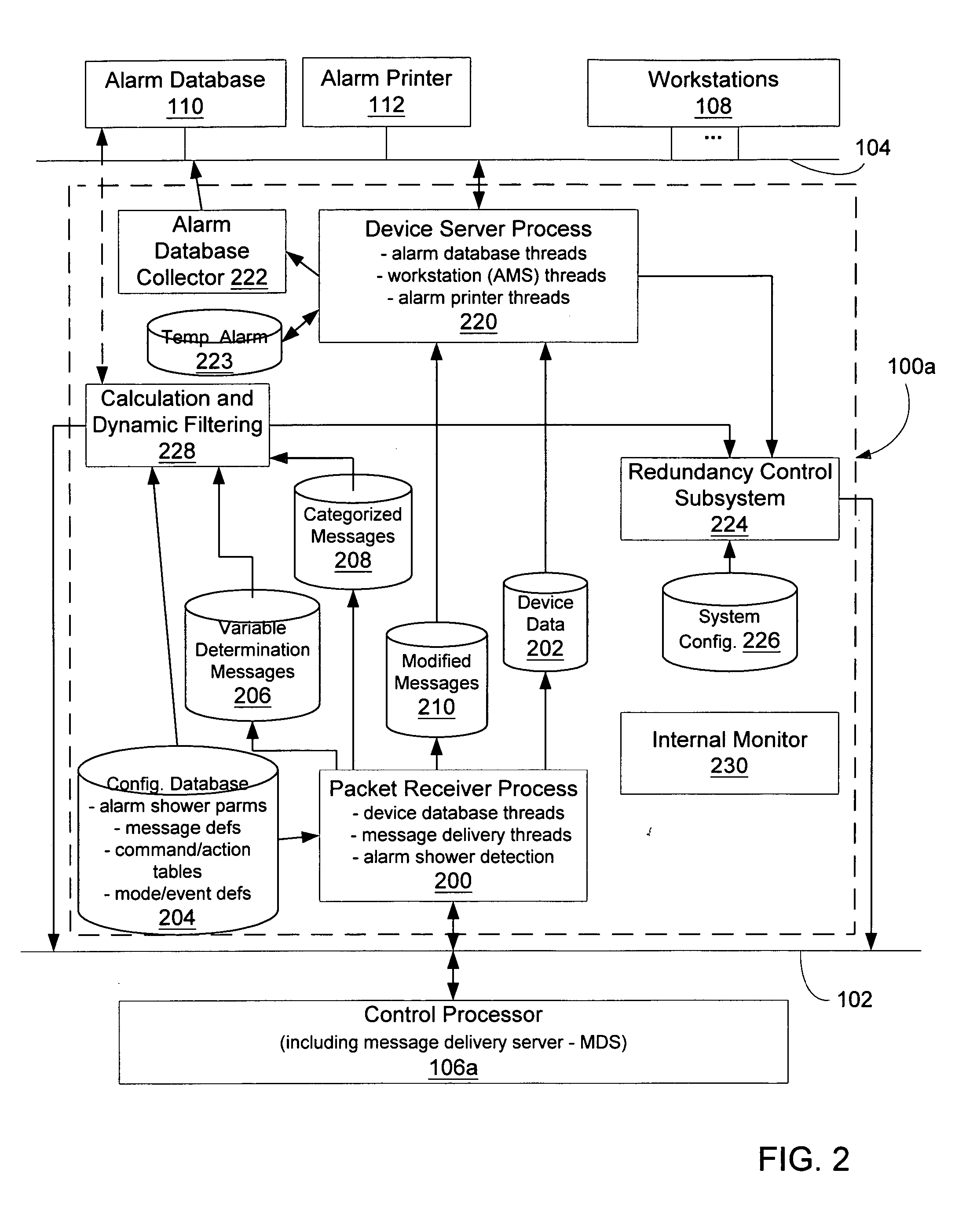

[0030] Structural and functional features of exemplary embodiments of the present invention are described herein with regard to configuration and runtime aspects of a message management facility. At runtime, the functionality of transmitting (“routing”) alarm messages, from control processors residing on a control network to one or more operator workstations (or other nodes) residing on an application network, has been extracted from the control processors and placed in one or more message management components executing on nodes coupled to a control network that hosts the control processors. The message management nodes are coupled to both the control network and the application network. Detecting and generating alarms takes place in the control processors (as before). Placing alarm routing functionality in a workstation or other node coupled to the application network reduces the computational and memory load on the control processor. Furthermore, placing routing functionality in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com