Heat exchanger assembly

a technology of heat exchanger and assembly, which is applied in the direction of heat exchange apparatus, stationary tubular conduit assembly, stationary conduit assembly, etc., can solve the problems of microchannels imposing a significant increase in pressure drop over more conventional flow channels, inability to transfer heat necessary for certain applications, and correspondingly high pressure drop in working fluids. achieve the effect of increasing the effective surface area, reducing pressure drop, and increasing frontal area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

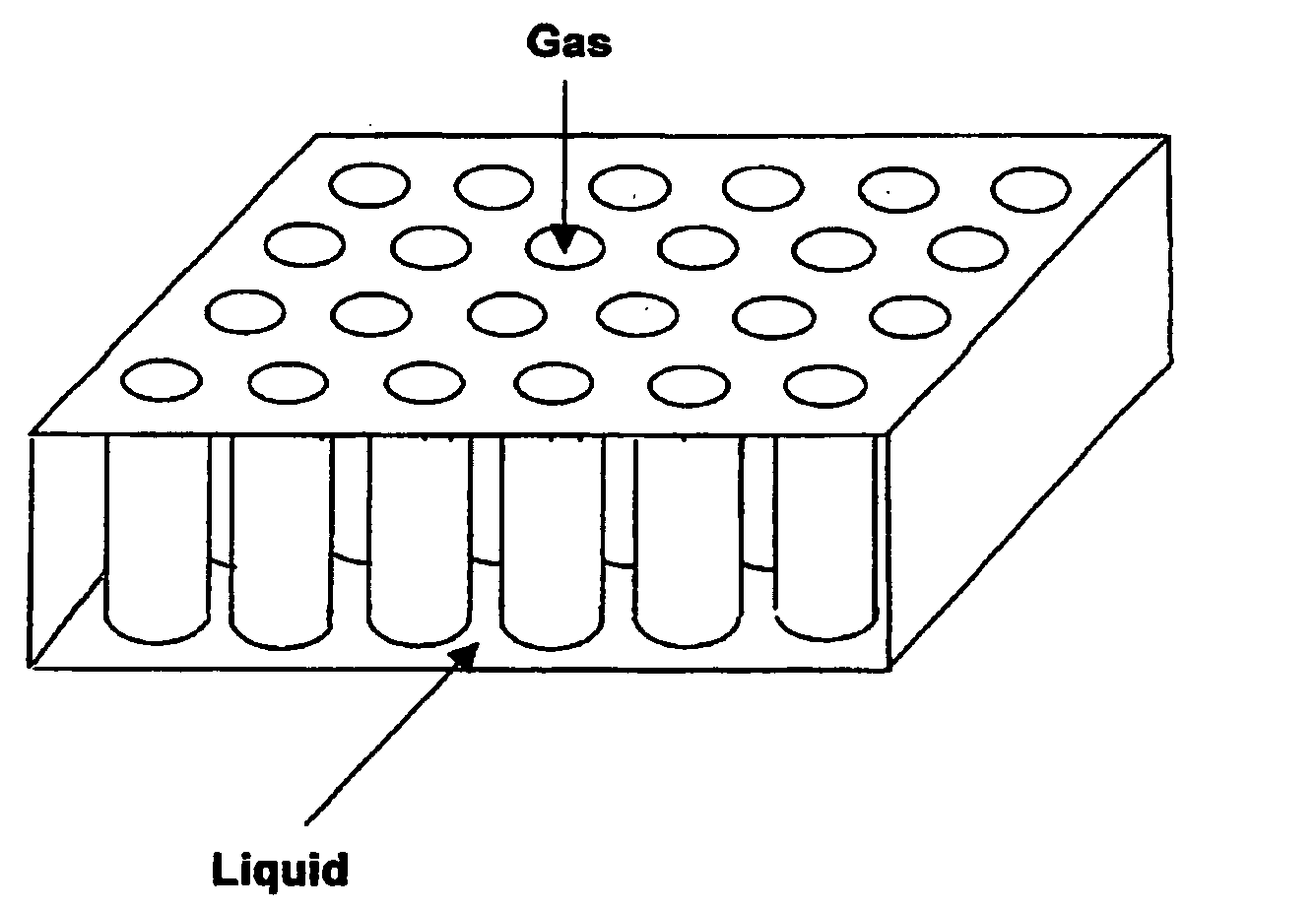

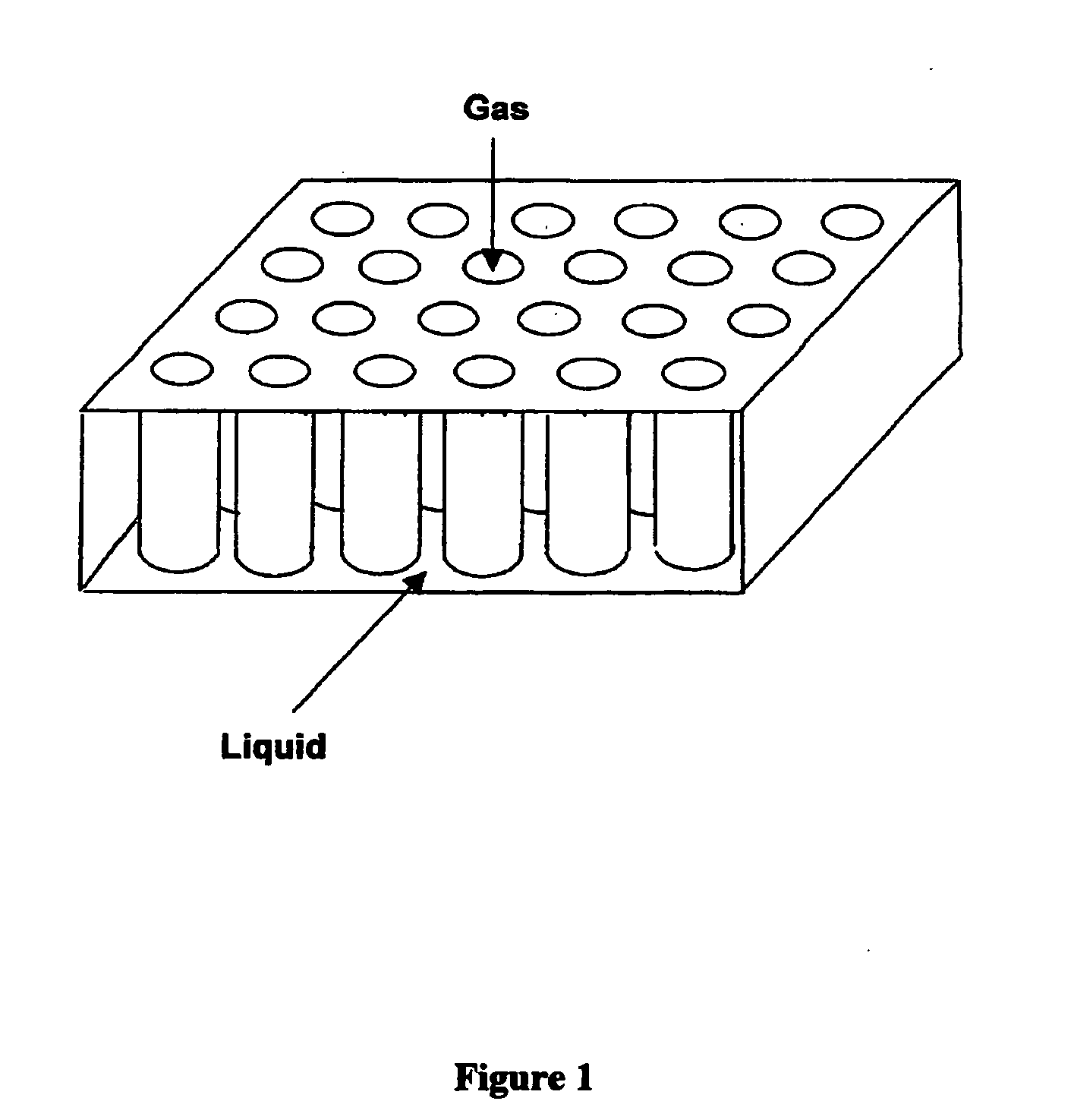

[0024] A schematic illustration of an embodiment of a thin panel heat exchanger is shown in FIG. 1 (not drawn to scale). In FIG. 1, the circular tubes are flow paths for a hot gas. The broad faces of the thin panel provide one large channel for the liquid flow path. This liquid flow path is broken up by the multitude of circular tubes. This arrangement creates a relatively large amount of primary surface area for heat transfer between the two fluids.

[0025] The flat panel illustrated in FIG. 1 is only an example of a thin panel heat exchanger. Any heat exchanger which has a shortest fluid flow channel less than 2.0 cm can be used to take advantage of the current invention.

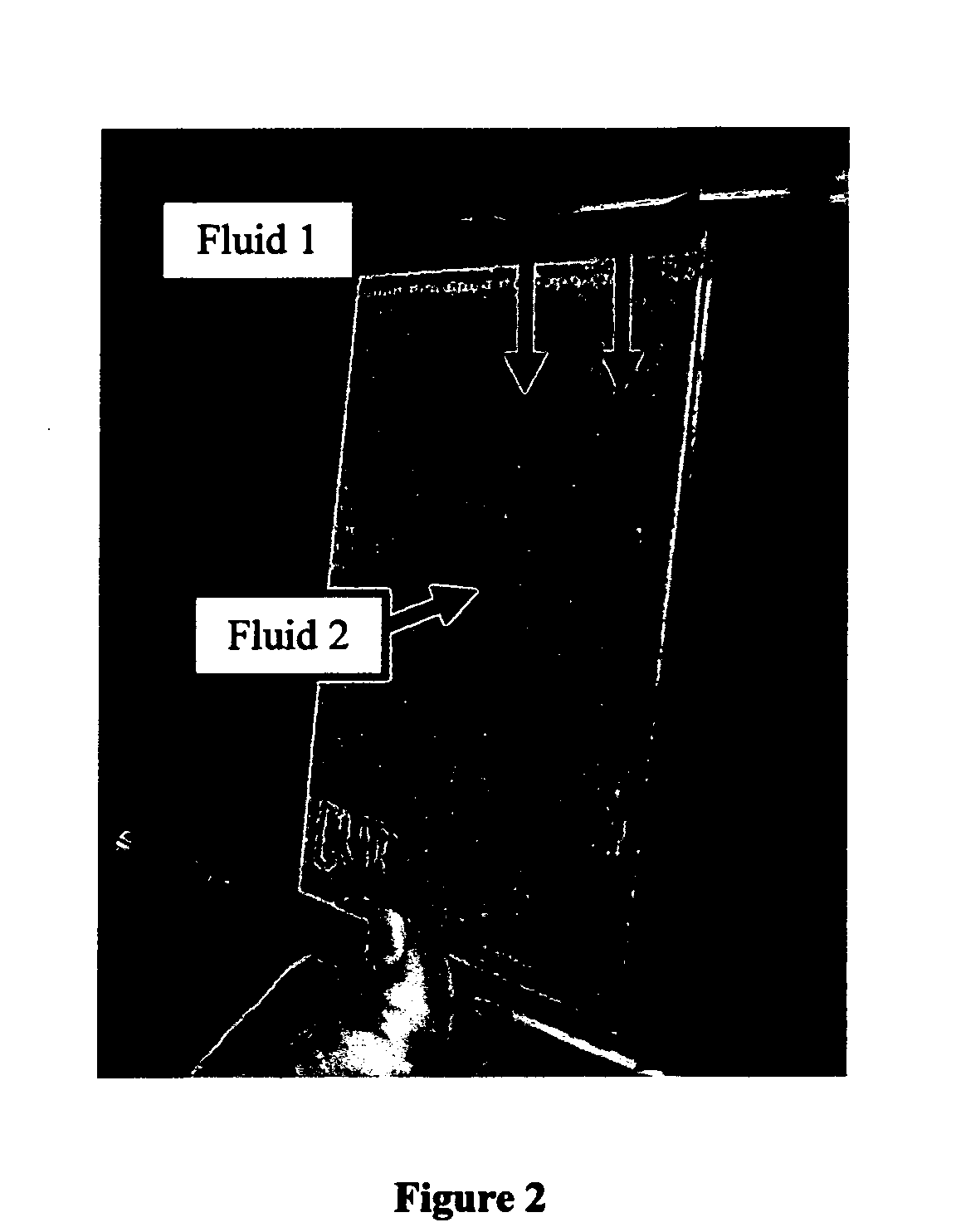

[0026]FIG. 2 is a picture of a thin panel heat exchanger made part of a heat exchanger system which delivers coolant to the panel through tubes. Each tube has a slot in which the panel may be mounted. The panel is brazed or otherwise fixedly connected to the tubes. Fluid 1, typically the coolant, is delivered to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com