Carrier for double side polishing

a carrier and polishing technology, applied in the direction of grinding/polishing apparatus, grinding machines, manufacturing tools, etc., can solve the problem of restricted thickness direction achieve the effect of reducing the polishing precision accompanying the deformation of the carrier, preventing the deformation of the large overhanging portion, and avoiding the failure of the carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

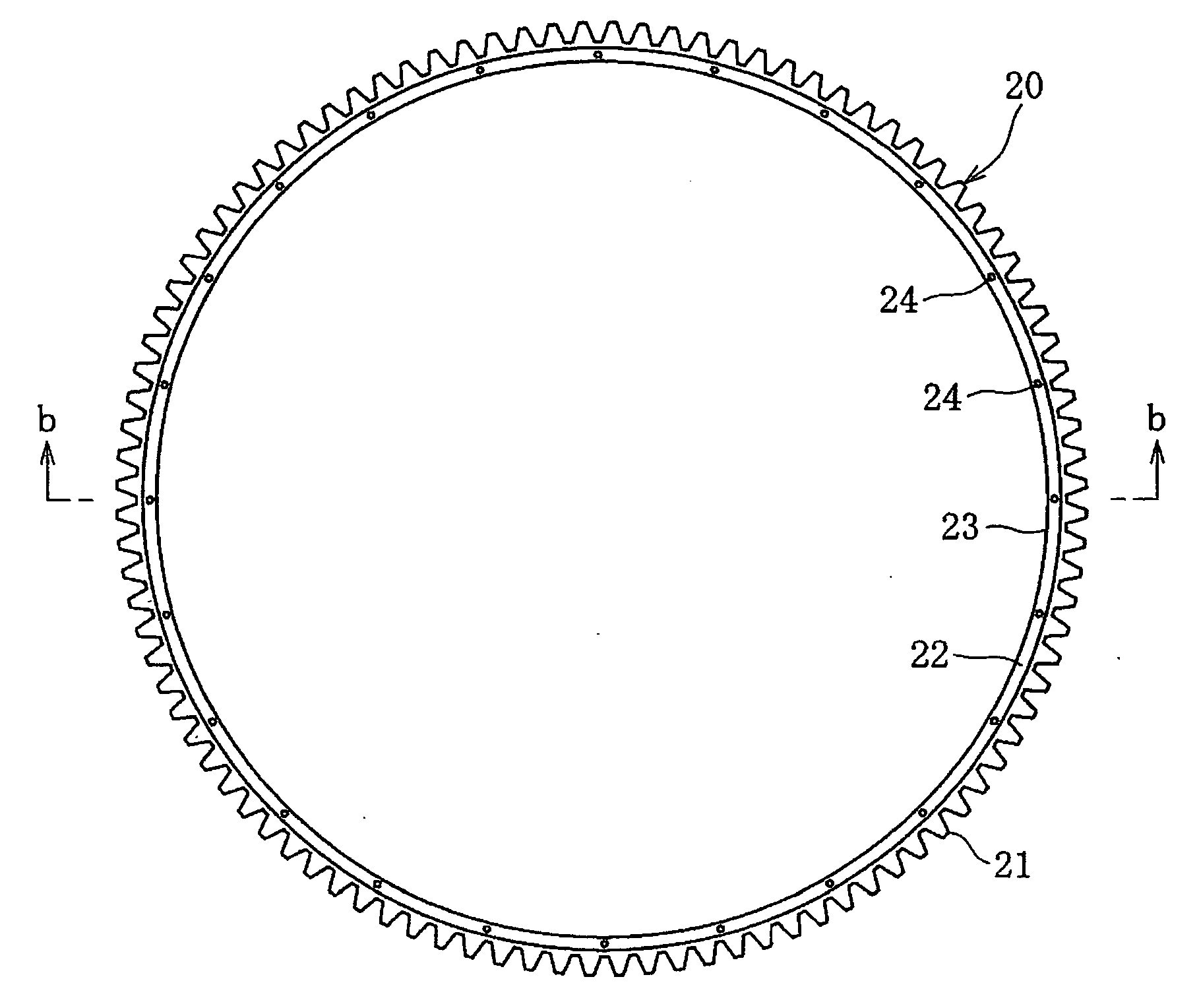

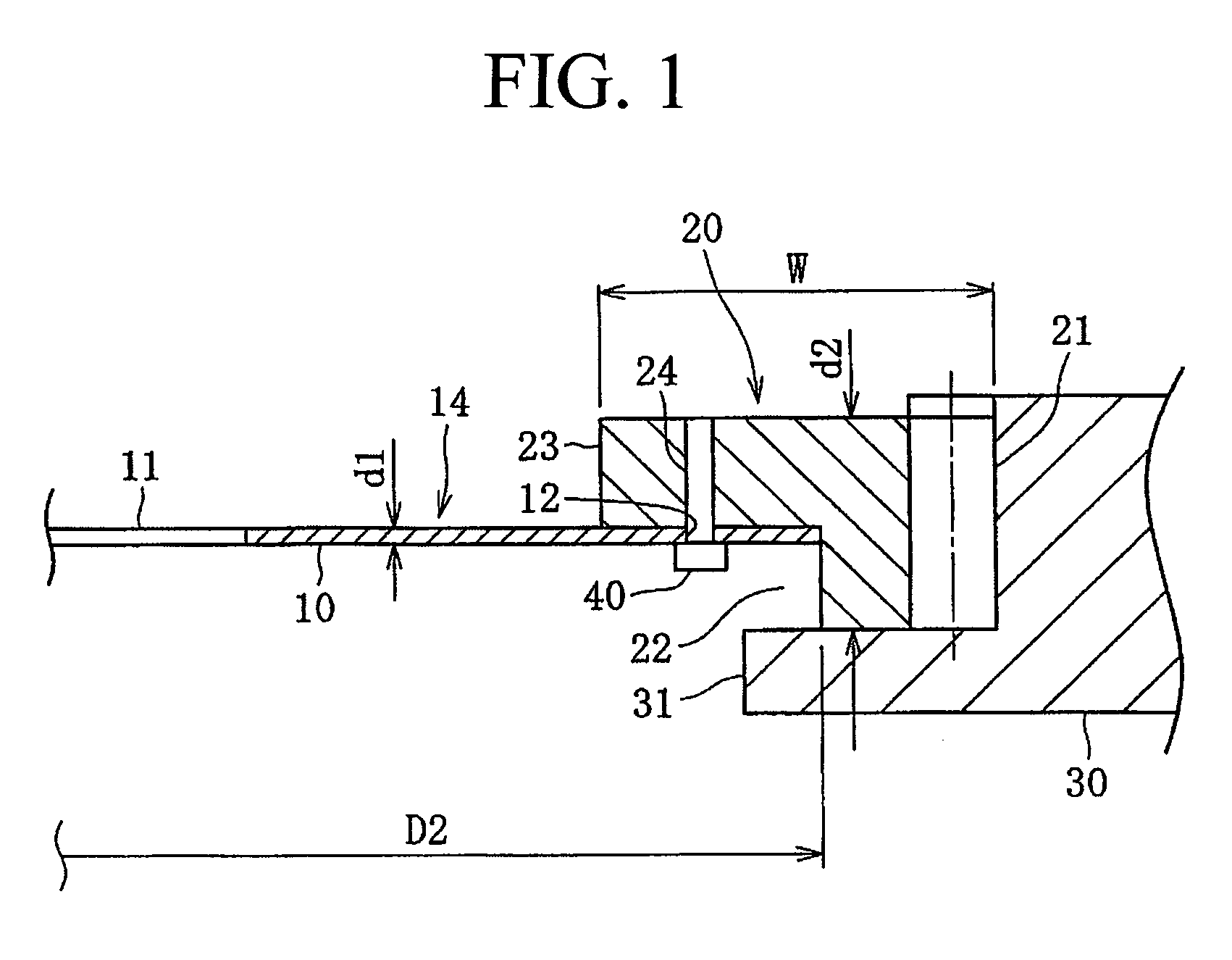

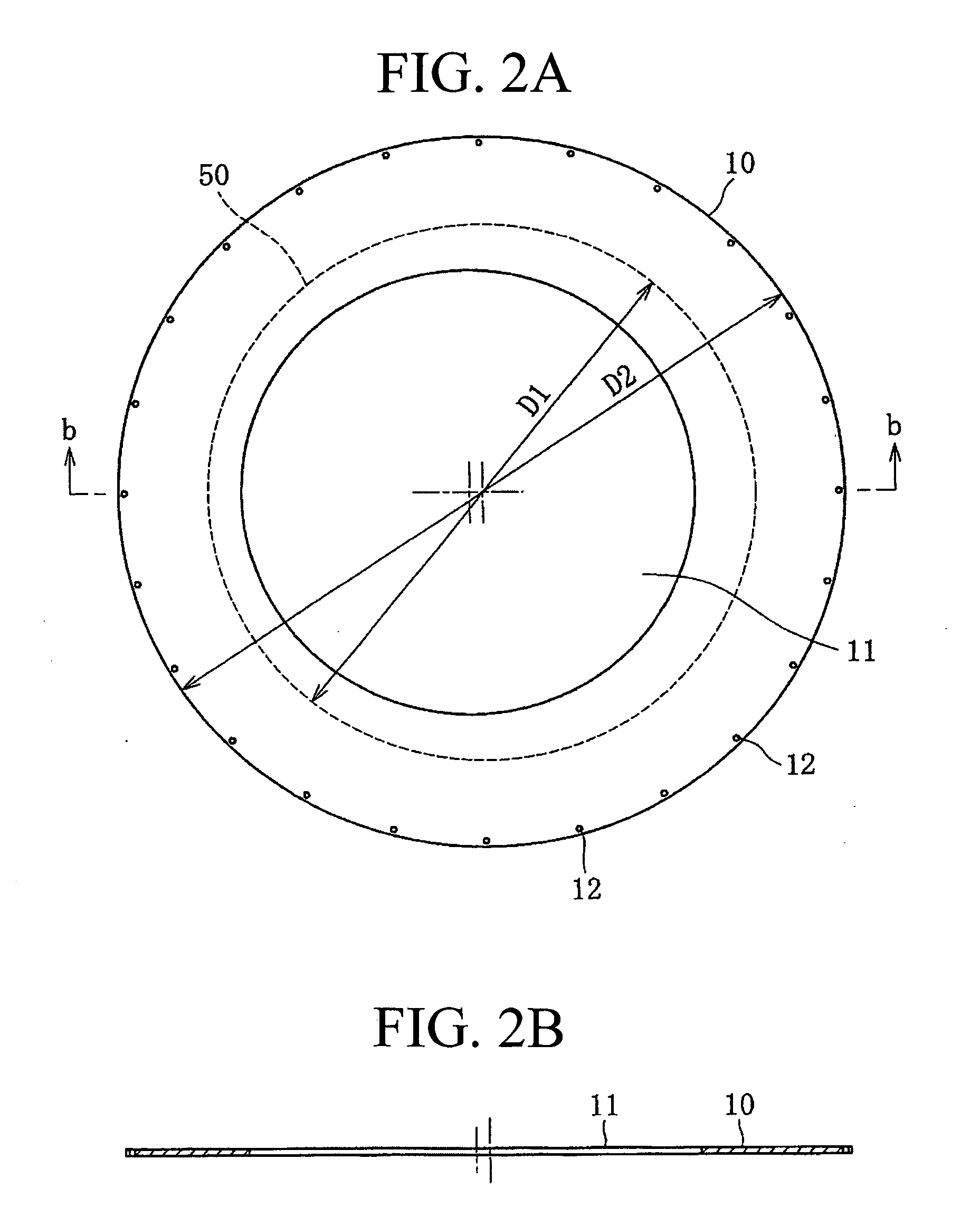

[0041]FIG. 1 is a partial cross section showing a constitution of a double side polishing carrier in the invention. FIGS. 2A and 2B are respectively a plan view and a cross section of a carrier body of the carrier. FIGS. 3A and 3B are respectively a plan view and a cross section of a support frame of the carrier.

[0042] In this embodiment, the double side polishing carrier is provided with a disk-shaped carrier body 10, and a ring-shaped support frame 20 attached to the periphery of the carrier body for supporting the main body. The support frame 20 is independent from the carrier body 10, and thus removable, and is fixed to the carrier body through screws 40.

[0043] The double side polishing carrier of this embodiment may be used for polishing a wafer of 300 mm in diameter. A workpiece housing hole 11 is provided in the central portion of the carrier body 10 for holding a workpiece. The workpiece housing hole is perforated in a concentric position, or in a slightly eccentric positio...

third embodiment

[0060]FIG. 5 is a plan view of a carrier body 10 used in the double side polishing carrier of the invention. Compared with the above-described carrier body 10, the carrier body 10 is different in that a plurality of workpiece housing holes 11 are provided to the carrier body 10. For example, to polish three wafers simultaneously, three workpiece housing holes 11, 11, and 11 each having a diameter slightly larger than the wafer diameter are arranged around the center at regular intervals. The diameter D1 of the surface plate is slightly larger than the diameter of the wafer. For example, for polishing wafers of 200 mm in diameter using the carrier of this embodiment, surface plates having a diameter D1 of 230 to 240 mm may preferably be used. The diameter D2 of the carrier body 10 and the size of the support frame 20 are the same as the other embodiment.

[0061] As described above, by removing the support frame 20 from the carrier body 10, the support frame 20 can be reused even when a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com