Nitriding method and device

a nitriding treatment and nitriding treatment technology, applied in adaptive control, process and machine control, instruments, etc., can solve the problems of unstable glow discharge, inability to apply uniform nitriding treatment, and part of the workpiece surface, so as to achieve satisfactory nitriding treatment, high accuracy, and high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

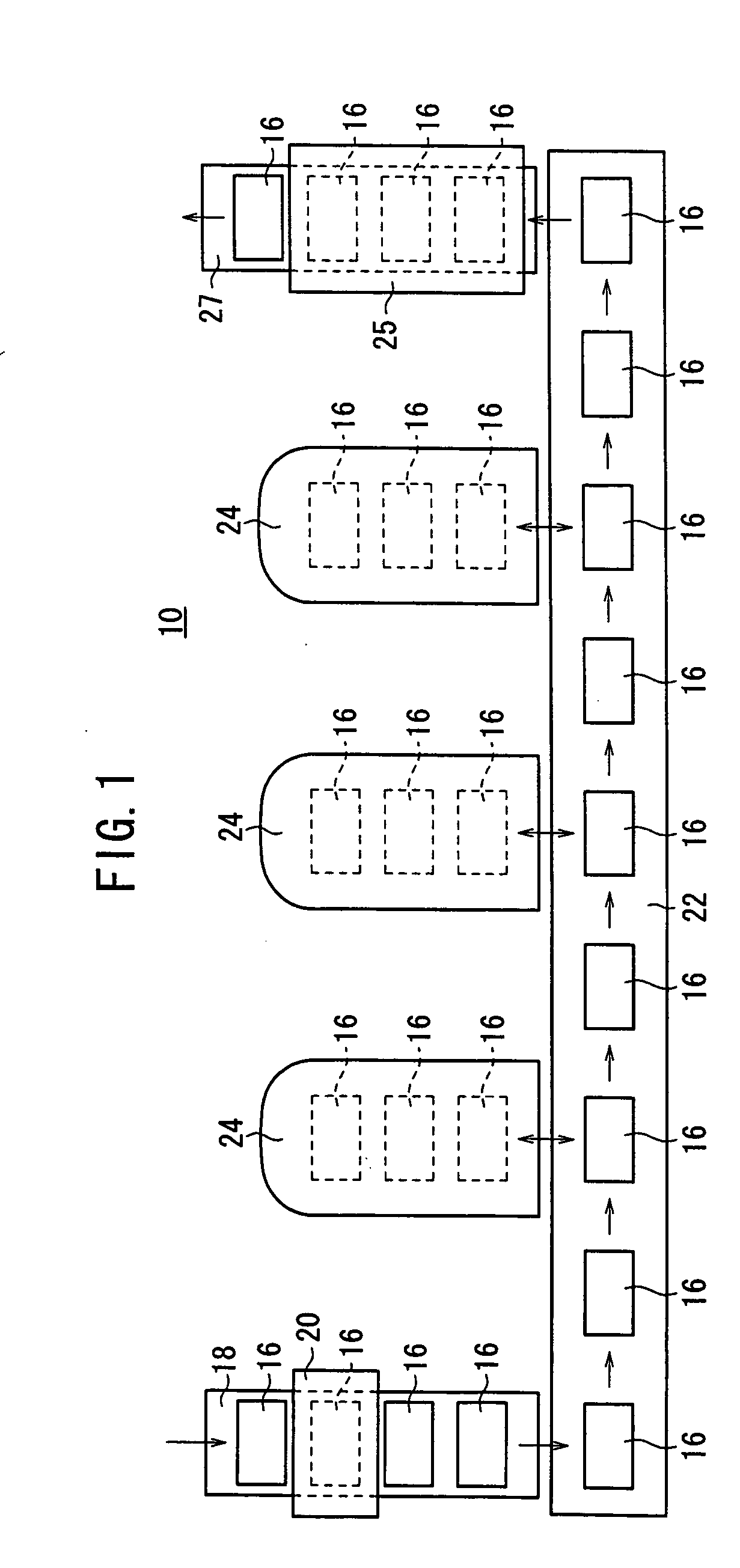

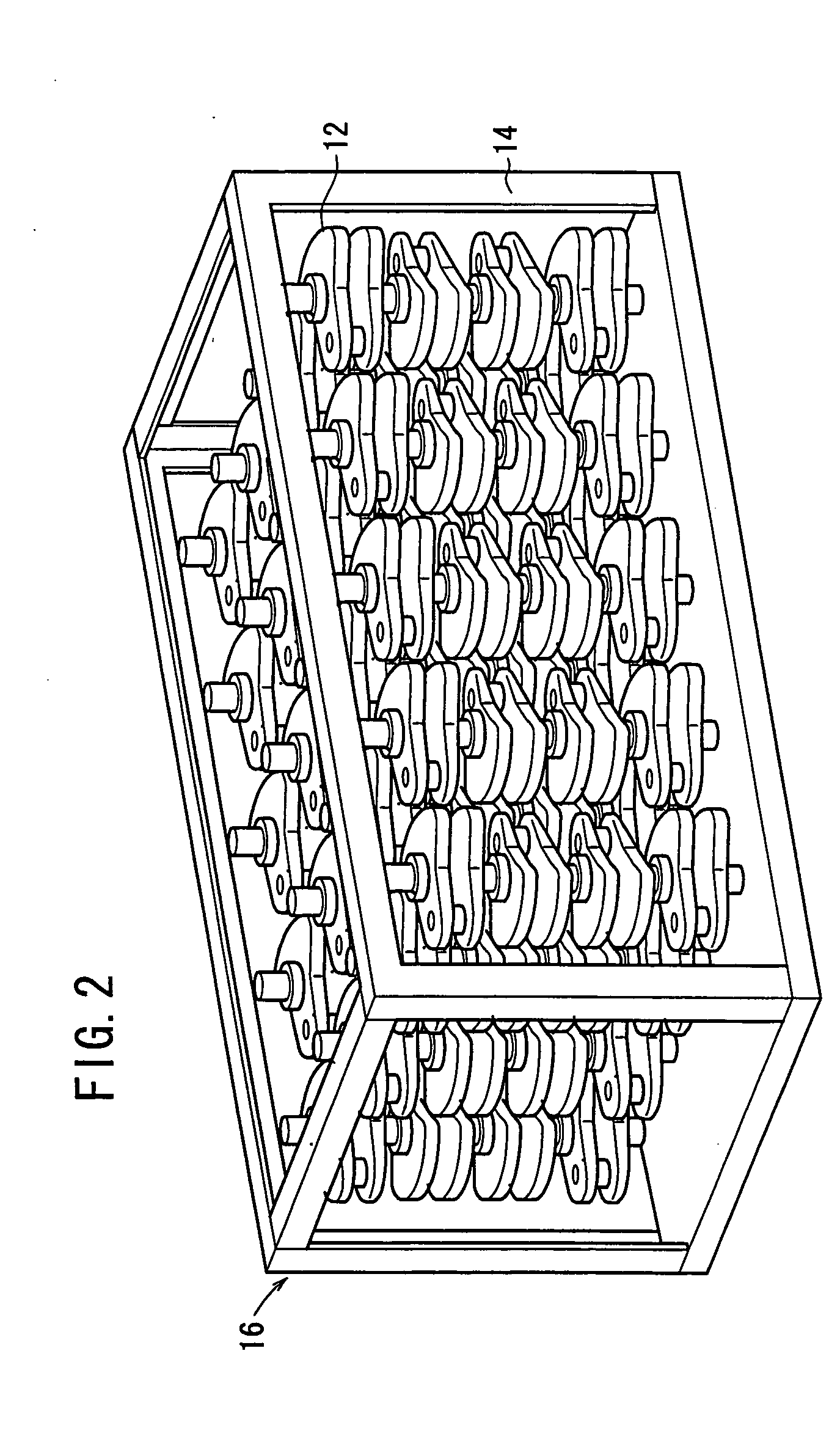

[0022]FIG. 1 shows a schematic arrangement of a nitriding treatment system 10 including a nitriding treatment apparatus according to an embodiment of the present invention. As shown in FIG. 2, a plurality of crank shafts 12 as workpieces are supplied to the nitriding treatment system 10 in a form of a magazine 16 in which the plurality of crank shafts 12 are positioned with a jig 14.

[0023] The nitriding treatment system 10 comprises a washing machine 20 which removes, for example, dust and oil adhered to the crank shafts 12 transported by a conveyer 18, a conveyer 22 which receives the washed crank shafts 12 from the conveyer 18 to transport them to respective work stations, lateral type heat treatment furnaces 24 which are arranged at the plurality of work stations along the conveyer 22, and a cooling tank 25 which cools the crank shafts 12 transported by a conveyer 27 connected to the terminal end of the conveyer 22.

[0024]FIG. 3 illustrates an arrangement of the lateral type hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com