Wear indication apparatus and method

a technology of wear indication and wear, which is applied in the direction of grinding/polishing apparatus, grinding machine components, manufacturing tools, etc., can solve the problems of tool working profile, wear, and tool effectiveness declin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

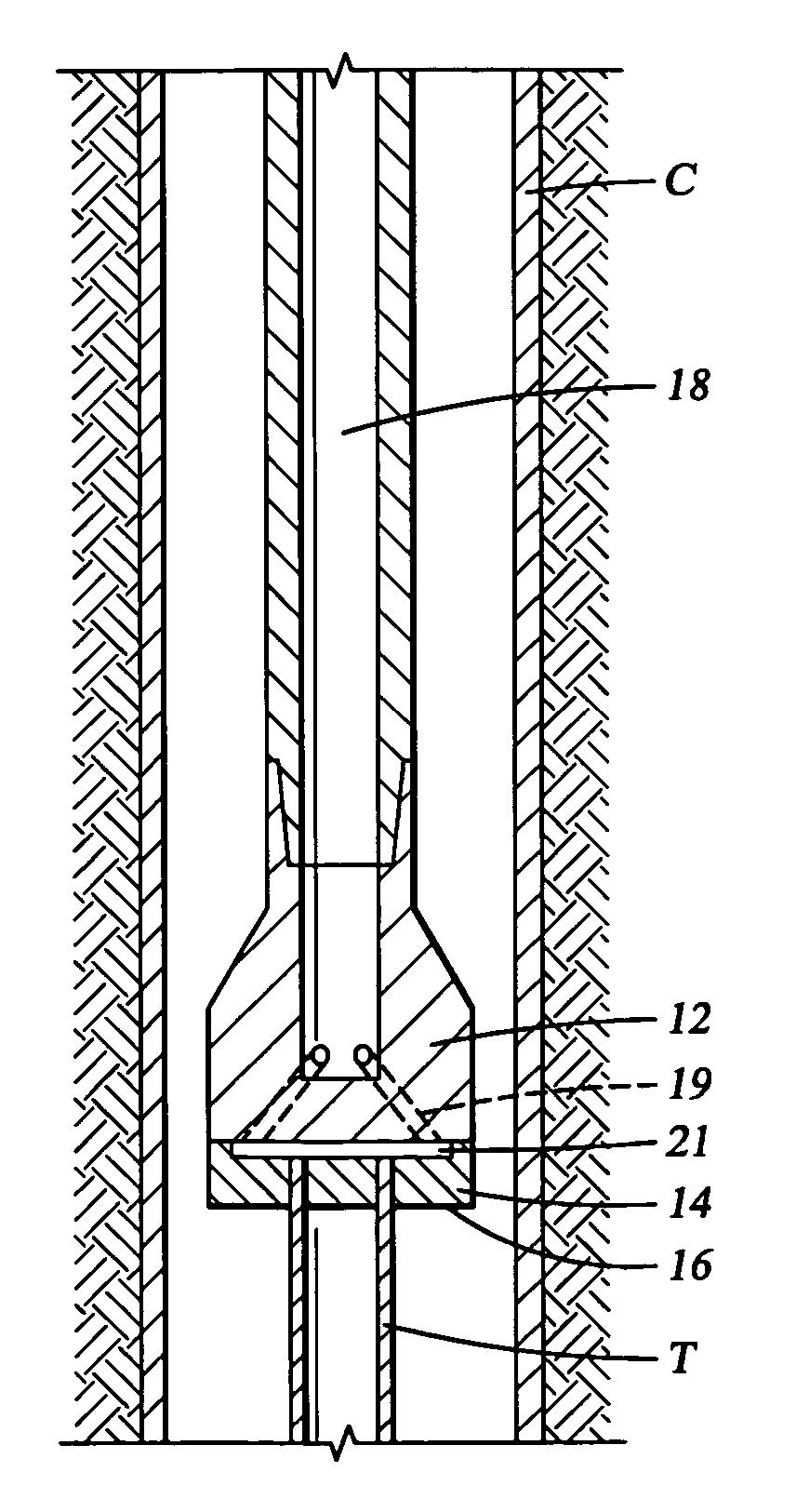

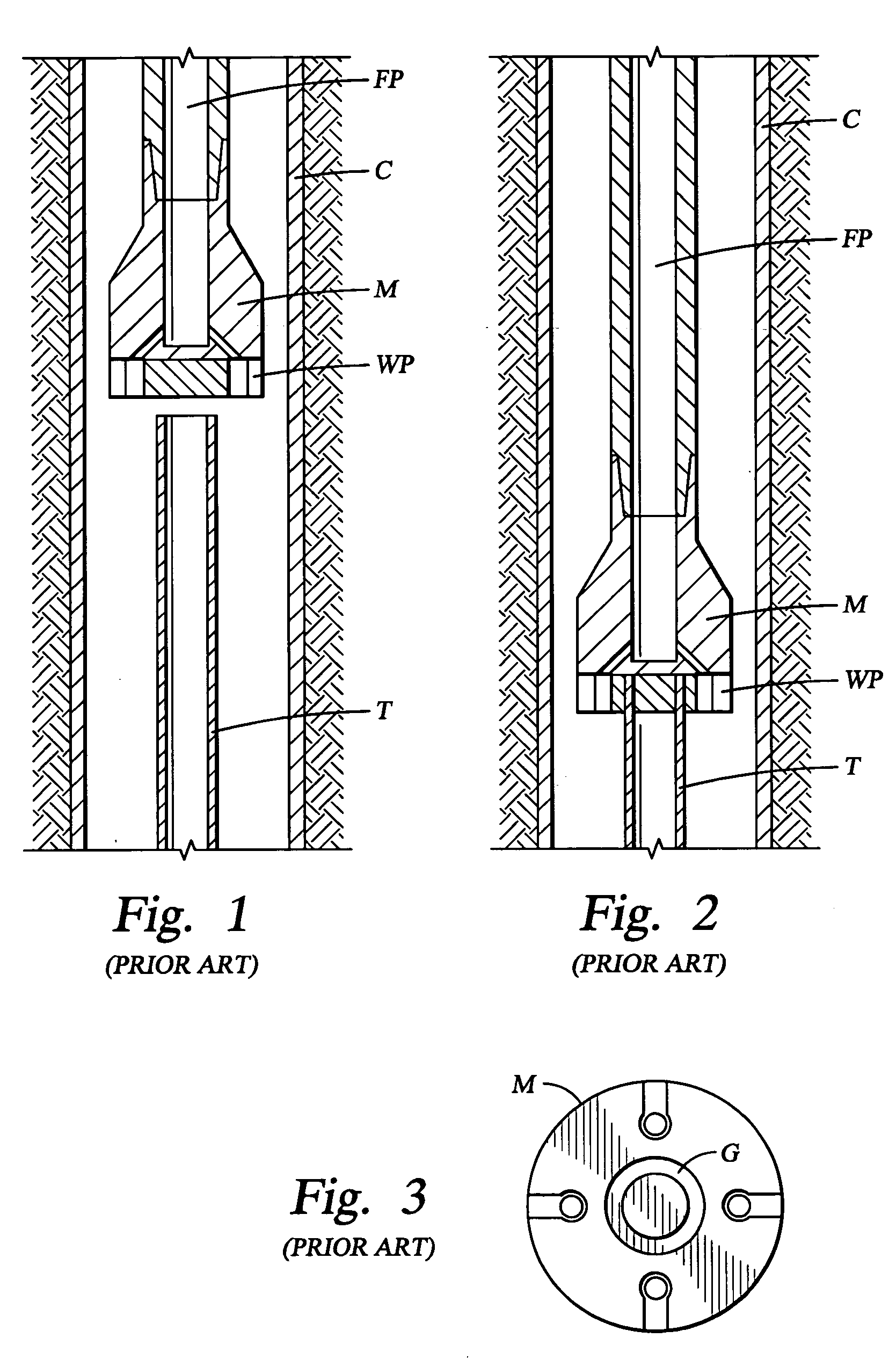

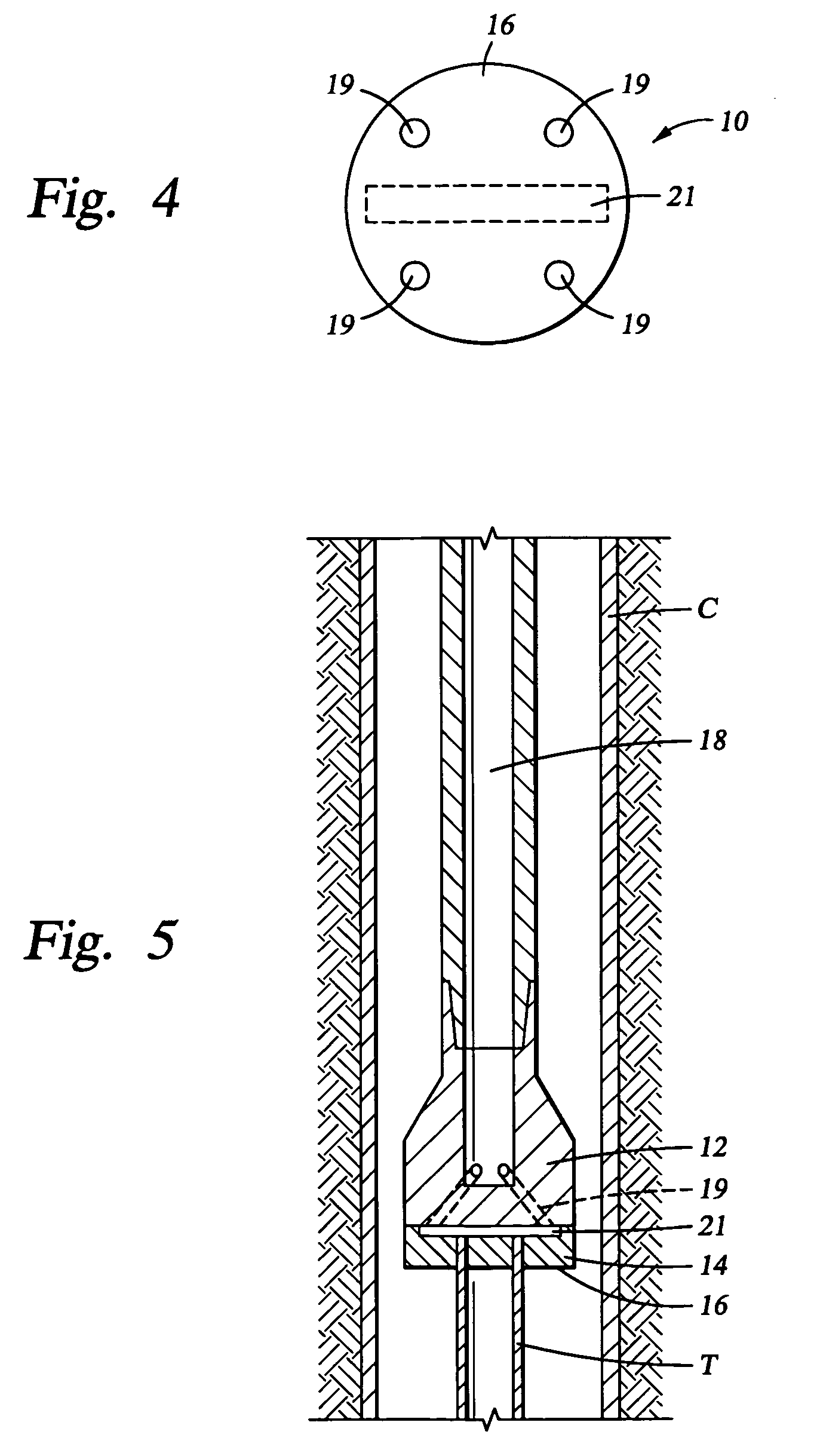

[0023]FIG. 4 shows an end view of a tool 10 according to the present invention. FIG. 5 shows the tool 10 in operation. The tool 10 has a body 12, on which is formed a working profile 14 in the form of a matrix of cutting elements. As the tool 10 is rotated, the leading face 16 of the working profile 14 contacts the tubular element T, and the working profile 14 mills away the tubular element T. As mentioned above, at the same time, the tubular element T will wear a circular groove in the working profile 14. A rectangular, closed-end, fluid passage 21 is formed within the working profile 14, imbedded below the leading surface 16 of the working profile 14. That is, the working profile 14 initially separates the fluid passage 21 from contact with the downhole structure, represented in this case by the tubular element T. Thus, the fluid passage 21 is represented as dashed lines in FIG. 4, and the nozzles 19 are shown leading from the fluid path 18 to the leading face 16. FIG. 4 indicates...

second embodiment

[0025]FIGS. 6 and 7 show the tool 10, which actually includes two additional types of wear indicators. That is, a plurality of closed fluid passages 20, in this case a plurality of branches, are embedded within the cutting profile 14. As with the rectangular fluid passage 21, these fluid branches 20 could be tubes 22 imbedded within the working profile 14, or they could simply be passages formed therein by any known means. These fluid branches 20 function in a similar fashion to the fluid passage 21. Also shown in this embodiment is another type of wear indicator, namely a plurality of pads 24 of wear resistant material.

[0026] When the working profile 14 has worn down as shown in FIG. 7, to the point where the wear resistant pads 24 contact the downhole structure, the wear resistant pads 24 begin carrying a substantial portion of the weight on the tool 10. This essentially prevents any further milling or cutting action, and as a result, the torque required to rotate the tool 10 is s...

third embodiment

[0027]FIG. 8 shows the tool 10, which also includes two types of wear indicator. As with the embodiment shown in FIGS. 6 and 7, the wear resistant pads 24 are shown here, and they function in the same way as described above. Additionally, this embodiment shows a capsule 28 of a discernible medium or material, which functions as a tell-tale agent. As with the rectangular fluid passage 21, the capsule 28 could be a tubes 30 imbedded within the working profile 14, or it could simply be a passage formed therein by any known means. The discernible material might be a magnetic powder, a chemical agent, or any other material which contrasts in some way, such as visibly, with the drilling or milling fluid being pumped through the tool 10. Other discernible properties might also be used, with the key point being that they are discernible to an observer or to some type of instrumentation, once they are released from the tool 10.

[0028] As the downhole structure wears away the working profile 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com