Method for preparing oil tea saponin

A technology of camellia oleifera saponin and camellia oleifera oil, which is applied in the field of preparation of saponins, can solve the problems of low total saponin content in crude extracts, difficulty in processing, long extraction time, etc., and achieve protection of composition and structure, low cost and high purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

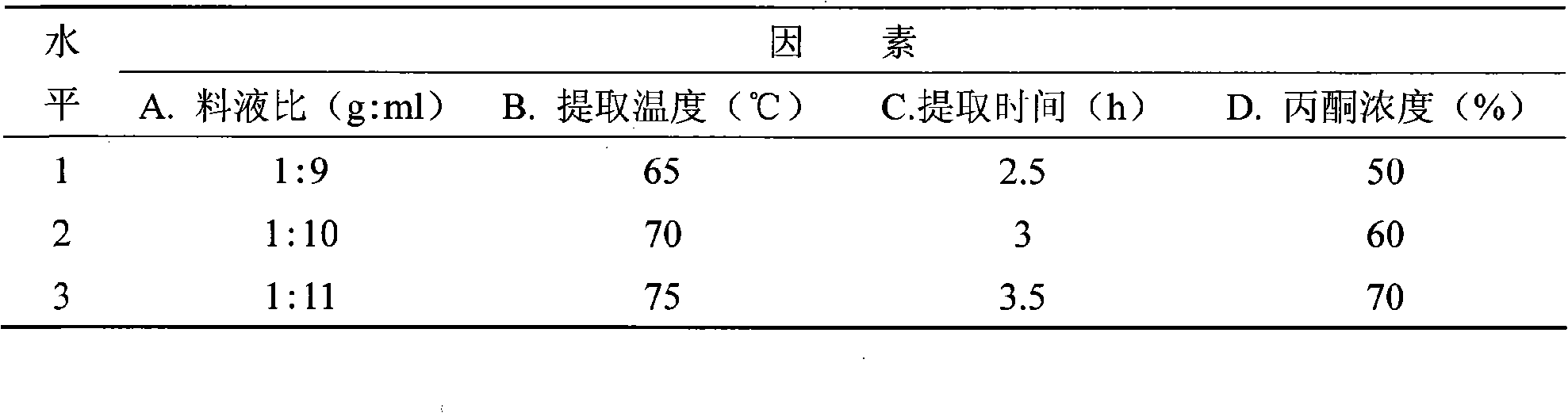

Embodiment 22

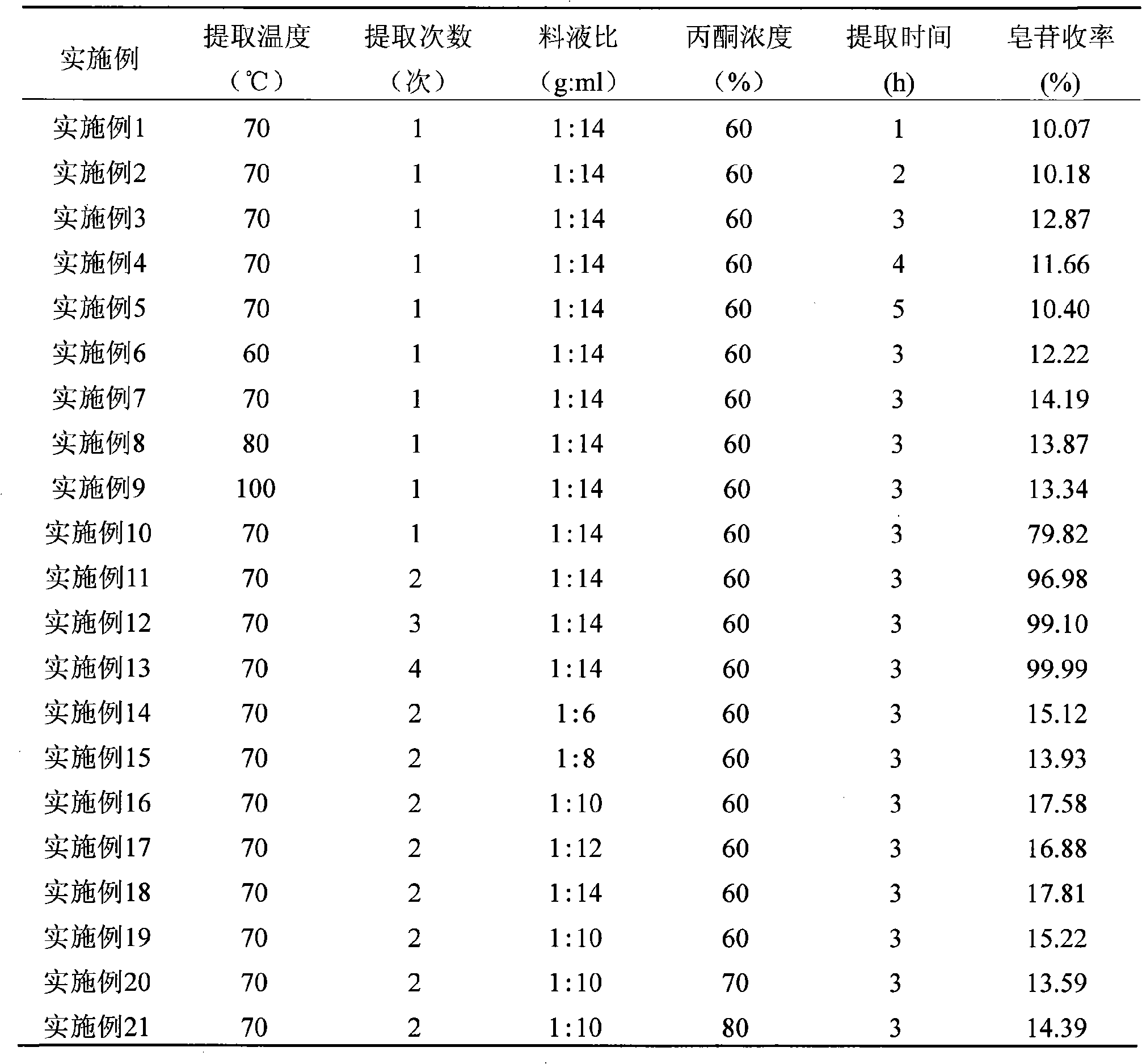

[0033] This embodiment is an orthogonal experiment to investigate the extraction process. The extraction process steps are the same as those in the aforementioned Examples 1-21. According to the results of the aforementioned Examples 1-21, 3 appropriate levels are selected for the 4 factors respectively, and L 9 (3 4 ) Orthogonal experiment schedule to investigate the optimal process conditions. The horizontal arrangement of the factors in the orthogonal experiment is shown in Table 2, and the experimental results are shown in Table 3:

[0034] Table 1

[0035]

[0036] Table 2

[0037]

[0038] table 3

[0039]

[0040] It can be seen from the analysis that the influence of each factor is A>B>C>D, that is, the extraction solvent times the amount> extraction temperature> extraction time> extraction solvent concentration, so the best process combination is A 1 B 2 C 2 D. 2 , that is, 9 times the amount of 60% acetone-water 70 ° C extraction twice, each time for ...

Embodiment 23~30

[0047] Crush the camellia oleifera after oil extraction as raw material for extraction: the extraction solvent is acetone-water solution with a concentration of 60%, the ratio of solid to liquid (g:ml)=1:9, the extraction temperature is 70°C, the extraction time is 3h, and the extraction times are 2 times; the solution was concentrated and dried, then dissolved in water and filtered, and the filtrate was passed through D 101 After the macroporous resin is adsorbed, the impurities are eluted successively with distilled water and ethanol solution according to the set conditions, and the target product is eluted with the ethanol solution of the set concentration. In the examples of this part, the flow rate of the eluent is 2BV / h , enrich the eluate containing the target product, and pass through D at an equal elution rate 941 The macroporous resin column is decolorized, concentrated and dried to obtain the camellia saponin product, the content (%) is determined, and the yield is ...

Embodiment 31

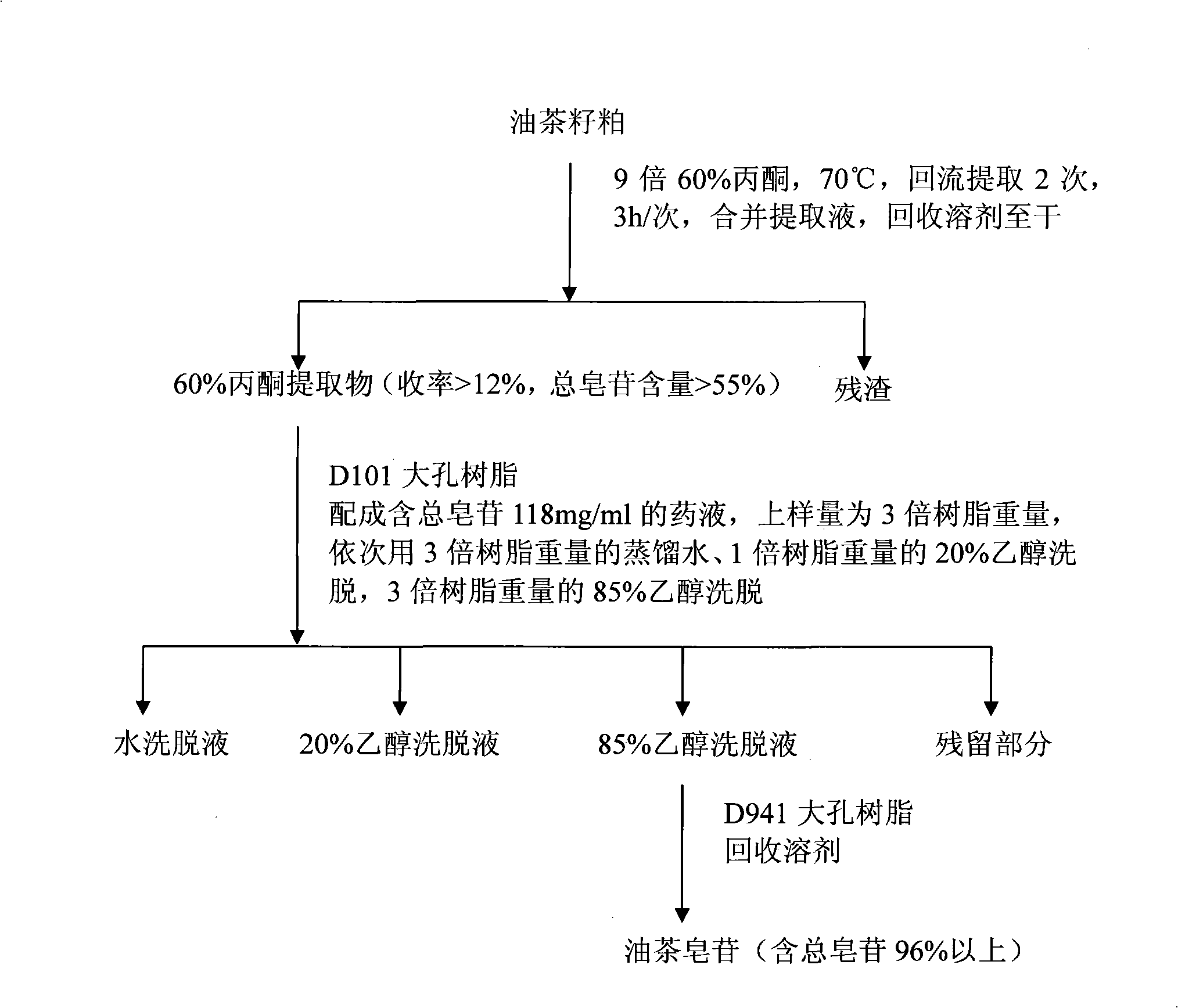

[0051] The technical process of this embodiment is as attached figure 1 shown.

[0052] Carry out solvent extraction with the Camellia oleifera oilseed dregs after oil pressing, the extraction solvent is the acetone-water solution that concentration is 60%, solid-liquid ratio (g:ml)=1:9, extraction temperature 70 ℃, extraction time 3h, extraction The number of times is 2 times; after testing, the content of saponin in 60% of the acetone extract is 55%;

[0053] After the extract was concentrated and dried, it was dissolved in water, filtered, and made into a liquid medicine containing 118 mg / ml of total saponins. The loading amount was 3 times the resin weight, and the filtrate was passed through D 101 After the macroporous resin is adsorbed, it is eluted successively with 3BV of distilled water, 1BV of 20% ethanol, and 3BV of 85% ethanol. The last part of the eluate is collected and passed through D 941 The macroporous resin column is decolorized, concentrated and dried to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com