Multilayer type printed-wiring board and method of measuring impedance of multilayer type printed-wiring board

a printed wiring board and multi-layer technology, applied in the direction of measuring leads/probes, inspection/indentification of circuits, instruments, etc., can solve the problems of inability to transmit exchange signals between the cpu module and the memory module, and the impedance is greater or smaller, so as to achieve easy and simple fashion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

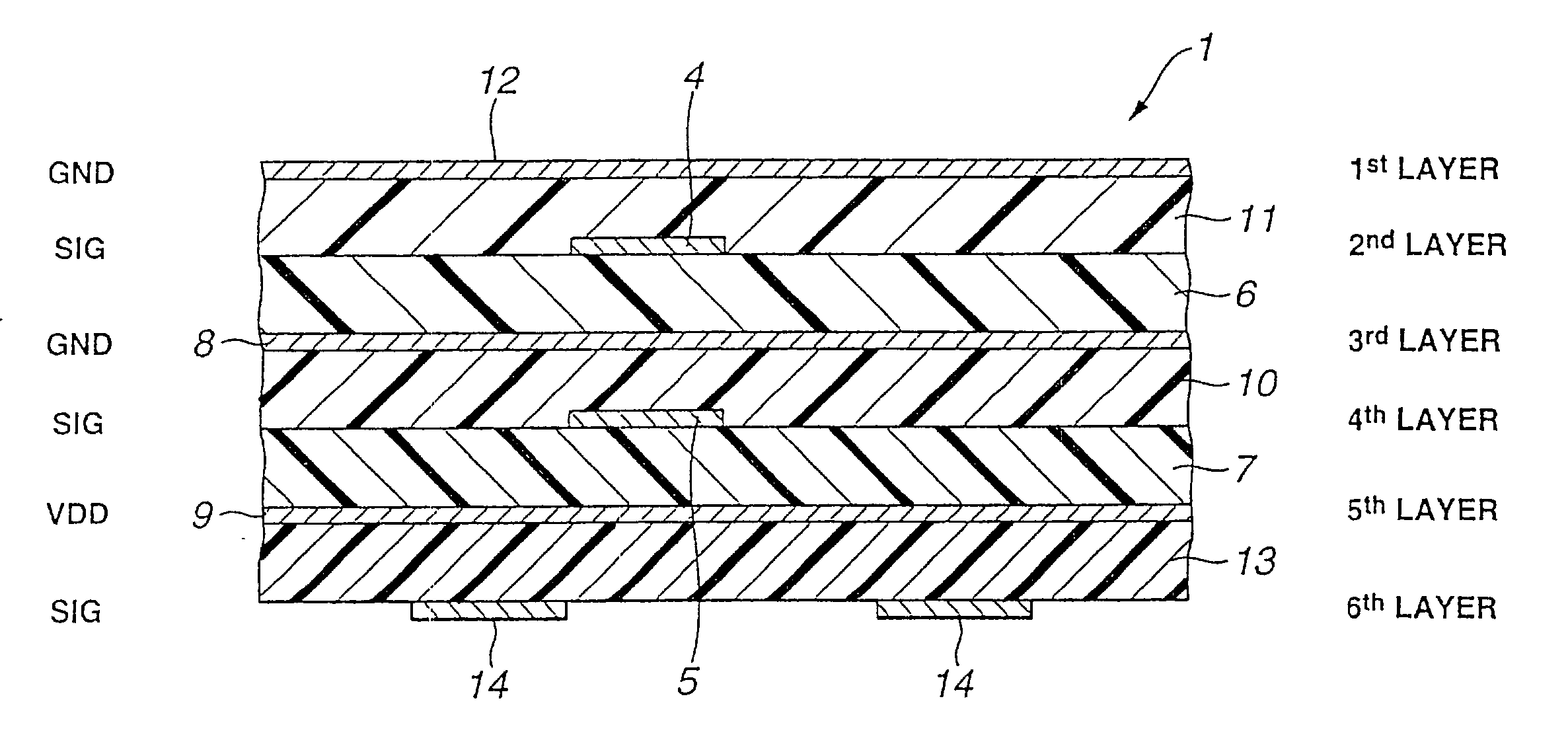

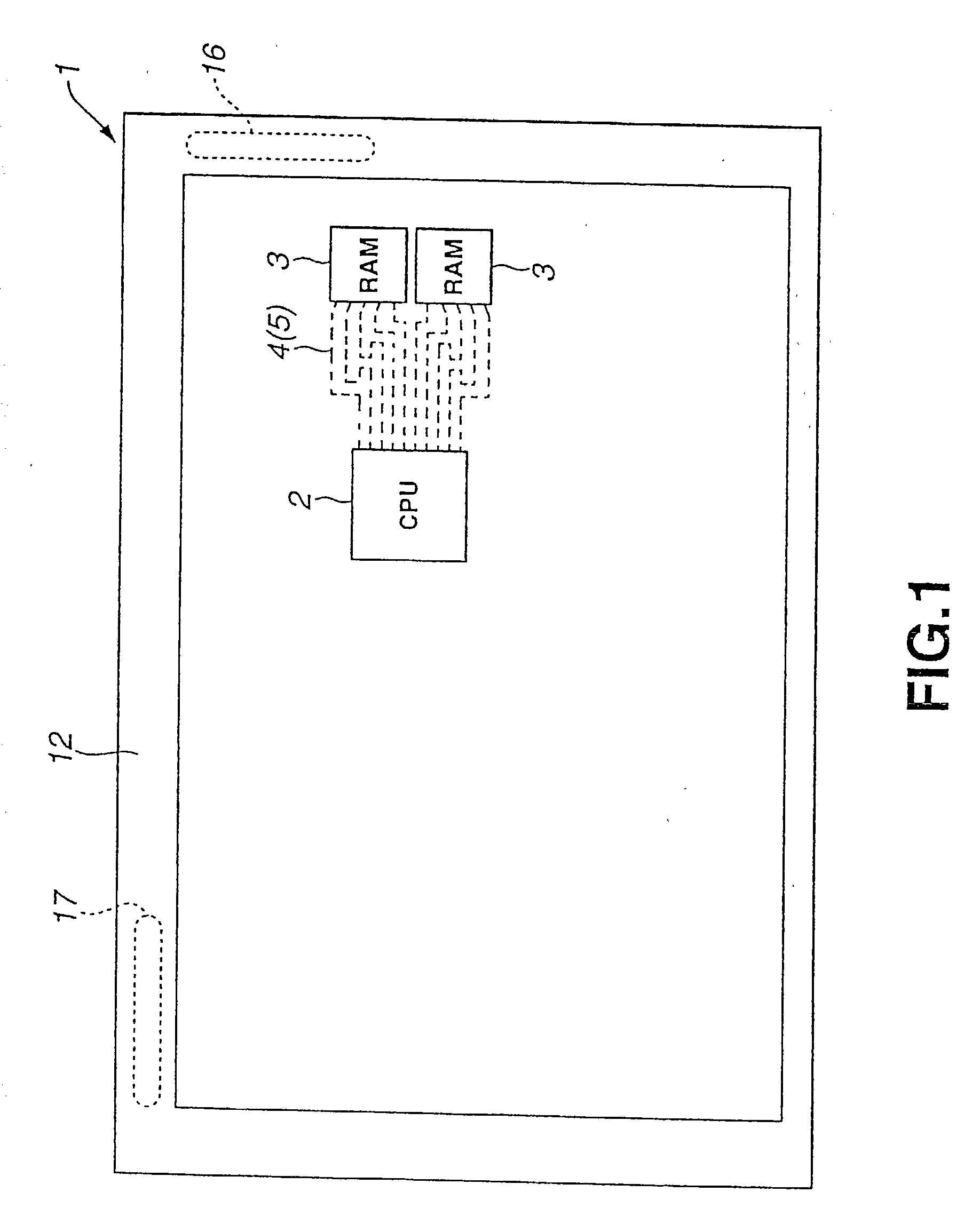

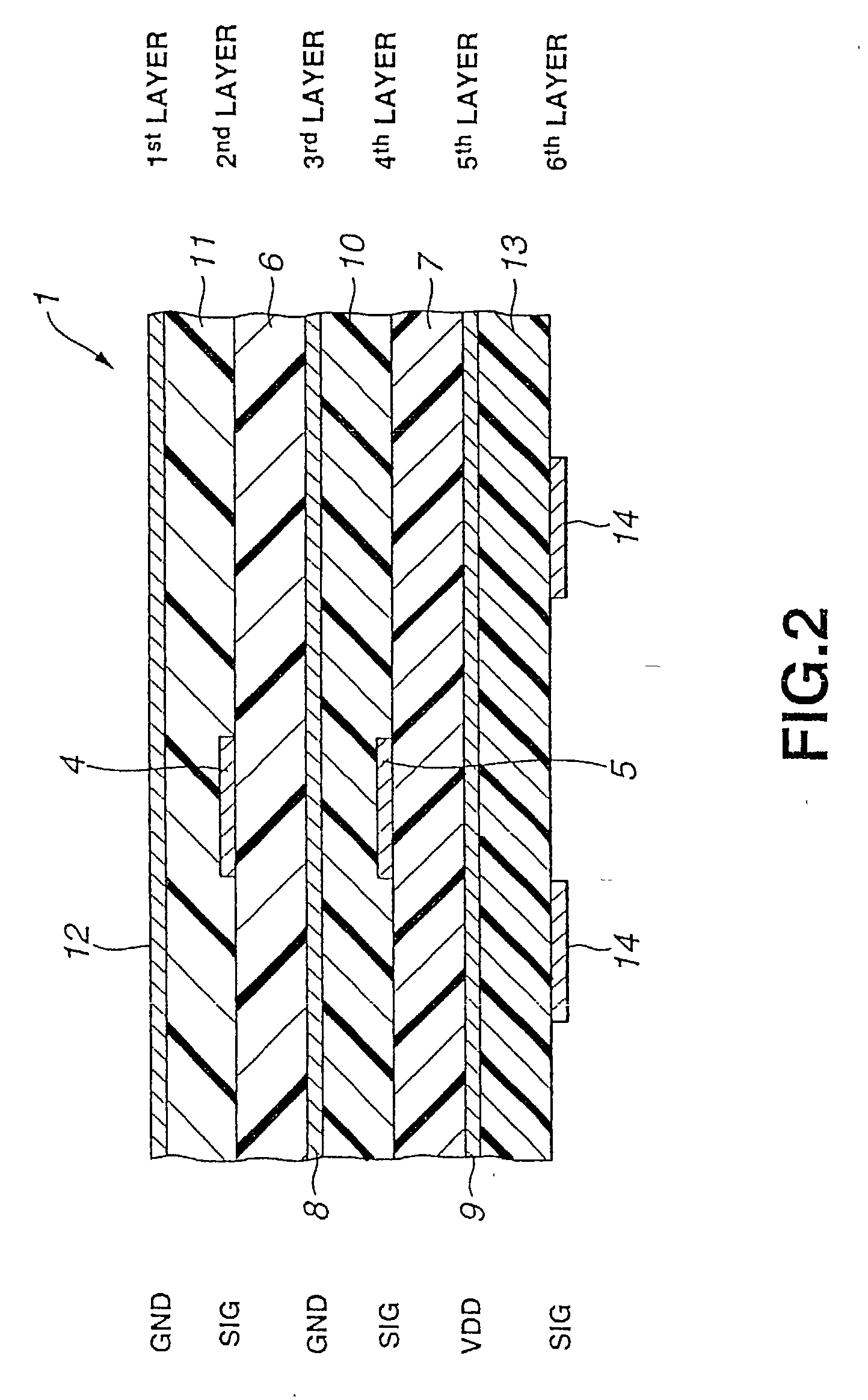

[0029] Now, a multilayer type printed-wiring board and a method of measuring the impedance of a multilayer type printed-wiring board according to the invention will be described in greater detail by referring to the accompanying drawing. FIG. 1 is a schematic plan view of an embodiment of multilayer type printed-wiring board according to the invention. The multilayer type printed-wiring board 1 has a total of six electro-conductive layers and is adapted to be used in a game machine for home use.

[0030] Referring to FIG. 1, the multilayer type printed-wiring board 1 comprises a CPU (central processing unit) module 2 and a pair of memory modules 3, 3 to be used for the CPU module 2 that are arranged on one of the opposite sides of the multilayer type printed-wiring board 1. The CPU module 2 has an operating frequency higher than that of any ordinary CPU and is adapted to operate at a frequency above about 290 MHz or more and typically between 300 MHz and 400 MHz so that it may be able...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com