CNC impact load deflector sleeve and removable collar for cable and post protection

a technology of impact load and deflector, which is applied in the direction of roadway safety arrangements, roads, construction, etc., can solve the problems of reducing the impact load effect, affecting the safety of pedestrians, so as to reduce the impact load effect and ensure the effect of sufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

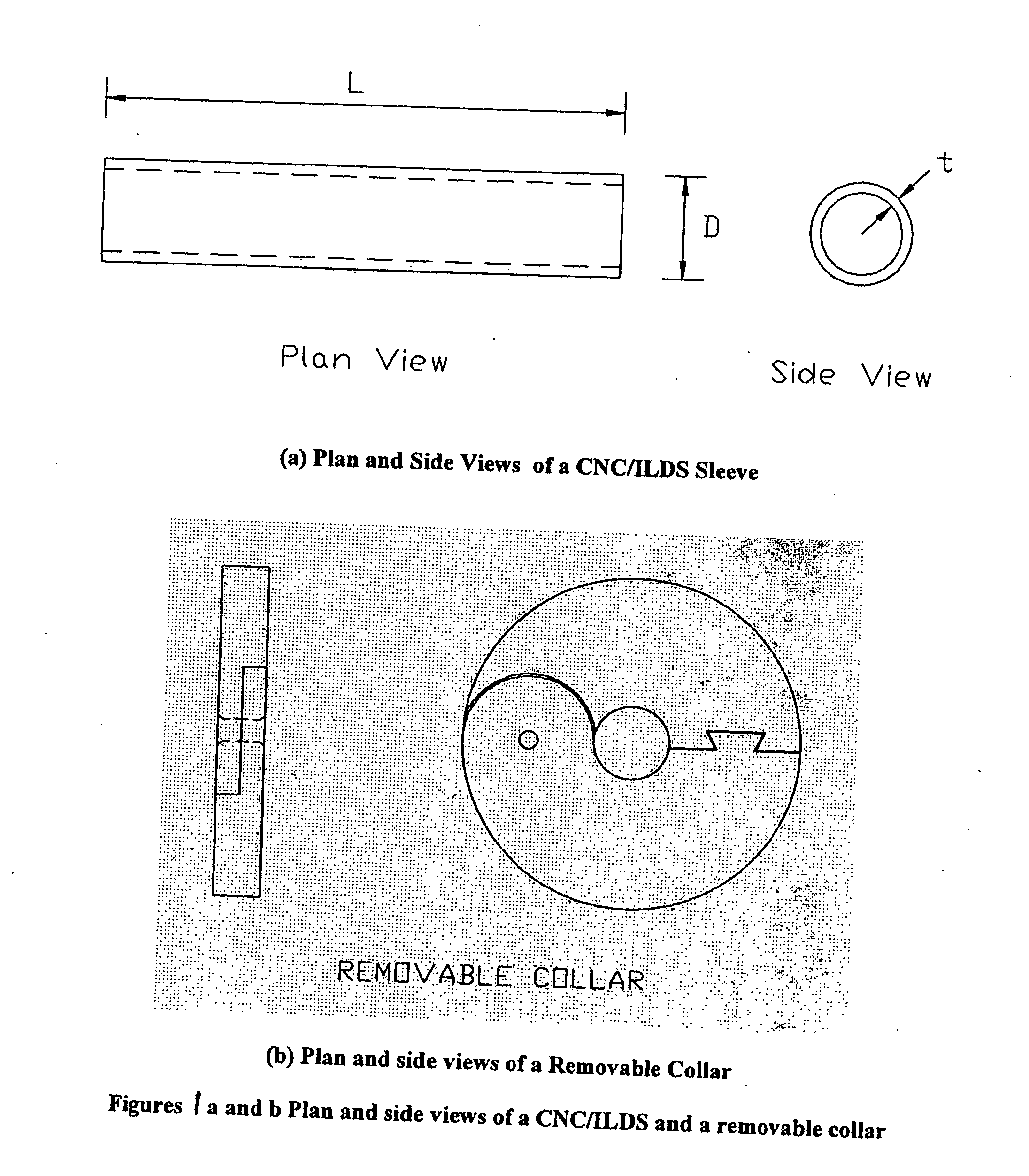

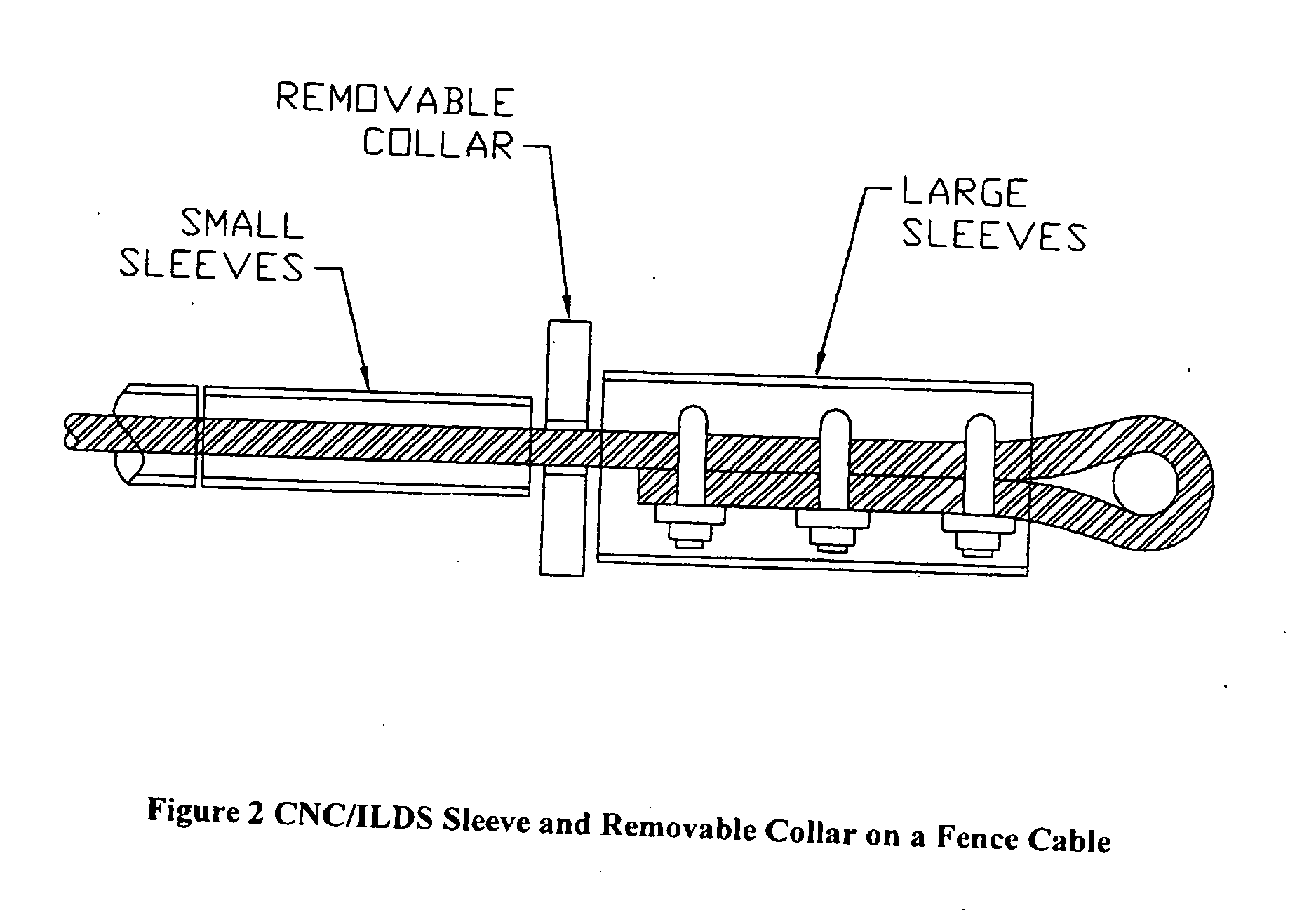

[0011]FIG. 1.a illustrates the plan and side views of a CNC / ILDS sleeve. It is a cylindrical tube of any appropriate material made to loosely embrace a cable or a post to allow its near frictionless rotation about the cable or post. This mechanism allows a CNC / ILDS sleeve to deflect a rolling rock upon contact and, thereby, reduce the failure potential of the fence cable. FIG. 1.b illustrates the RC collar that can be easily installed and removed from a cable for easy construction and repair. The collar is positioned between two different-size CNC / ILDS sleeves to prevent a smaller sleeve from slipping into a larger one. FIG. 2 shows a cable with CNC / ILDS sleeves and a RC collar between two sleeves.

Installation of CNC / ILDS

[0012] To mitigate the failure potential of a RFMFS, CNC / ILDS sleeves can be installed along the whole length of the cable and / or the post. The functionality of the CNC / ILDS is explained as follows: [0013] A CNC / ILDS can rotate nearly freely around the cable and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com