Thermoformable acoustic product

a technology of acoustic products and acoustic components, applied in the field of sound absorption materials, can solve the problems of application similarly not addressing the practicality of achieving effective sound absorption solutions, and the prior art does not address the practicality of achieving effective sound absorption solutions, and achieves enhanced and consistent acoustic properties, favorable aesthetic appearance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

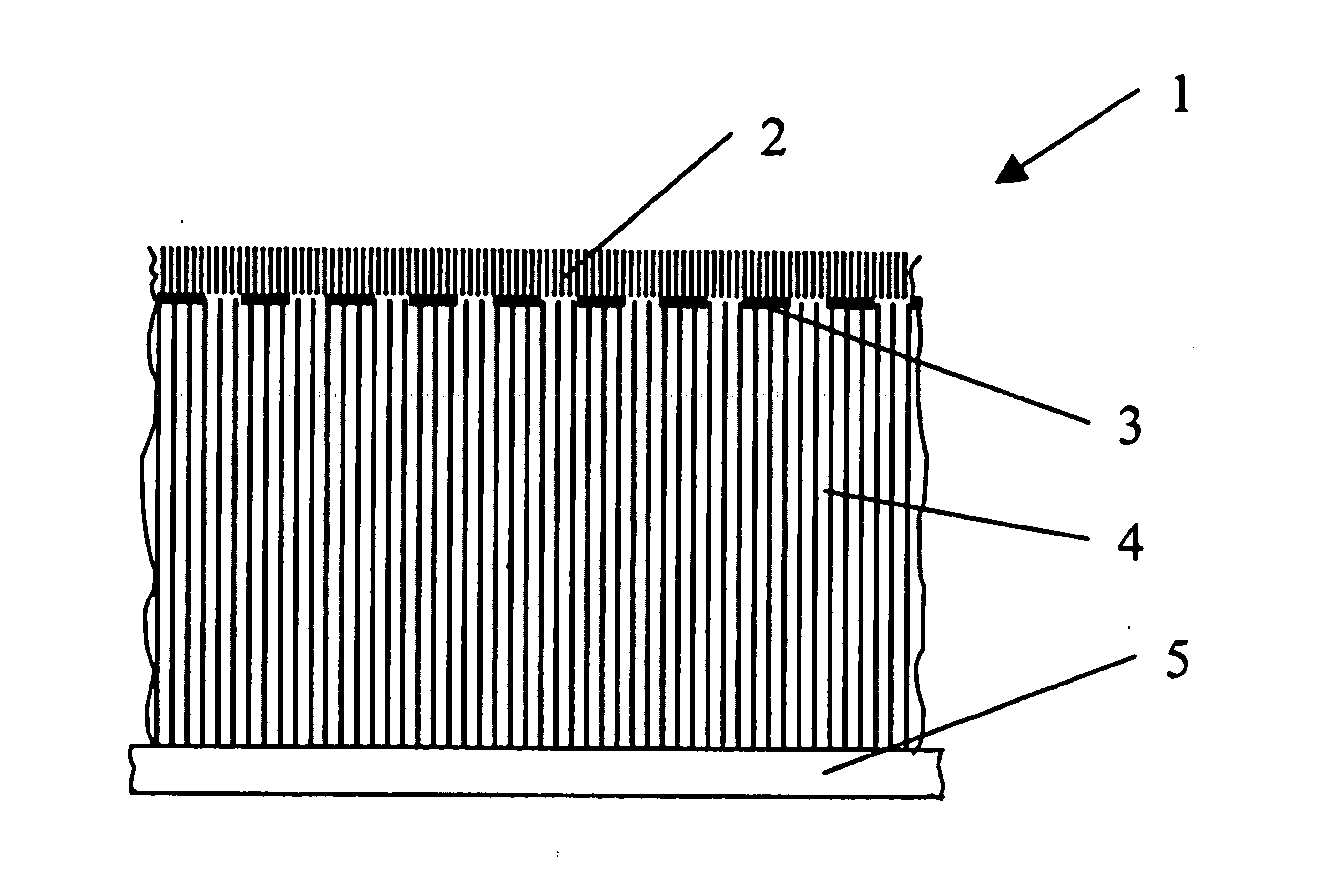

[0084] A compressed flow resistive sheet comprising both high melt and low melt bicomponent polyester fibers was formed in accordance with PCT / AU01 / 00880. The sheet comprised 70% 4 denier low melt bicomponent fibers, and 30% 6-denier high melt polyester staple fibers. The total mass of the flow resistive sheet was 1000 g / m2.

[0085] A vertically-lapped spacer web made from 30% 2-denier bicomponent polyester fibers, 20% 12-denier and 50% 6-denier polyester staple fibers was laminated to the flow resistive sheet with heat reactivated hot melt powder applied at a rate of 30 g / m2. The total mass of the spacer layer was 800 g / m2.

[0086] The resultant product had a total flow resistance of 3200 Rayls and was 23 mm thick.

[0087] The composite was tested in an alpha cabin, using Toyota test specification TSL 0600G—Test method for acoustic materials, for sound absorption and transmission loss and the results were compared with a target specification based on the prior art, with the same total...

example 2

[0088] Three samples of spacer layers similar to the spacer layer formed in Example 1 were formed using 2.5, 3.7 and 6 denier average fiber size except that the spacer layer had a total mass of 600 gsm. A plot of the sound absorption coefficient versus frequency of the three samples is shown in FIG. 8.

example 3

[0089] A similar product was formed to the product formed in Example 1 except that the spacer layer was 13 mm thick and had a total mass of 400 gsm. FIGS. 9 and 10 show the effect of the thickness of the spacer layer on the sound absorption coefficient and the transmission loss at frequencies between 200 Hz and 6300 Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com