Model railroad system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

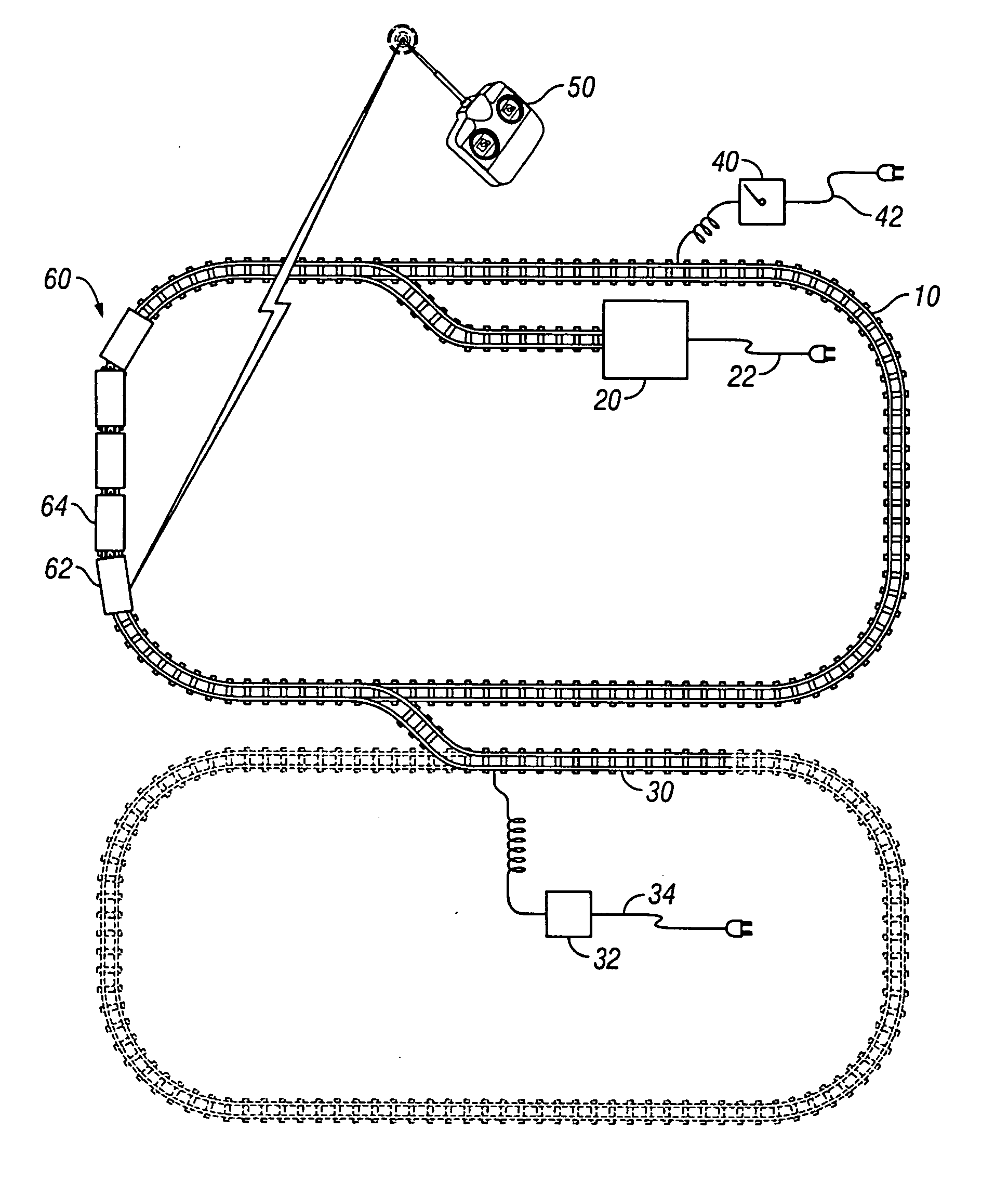

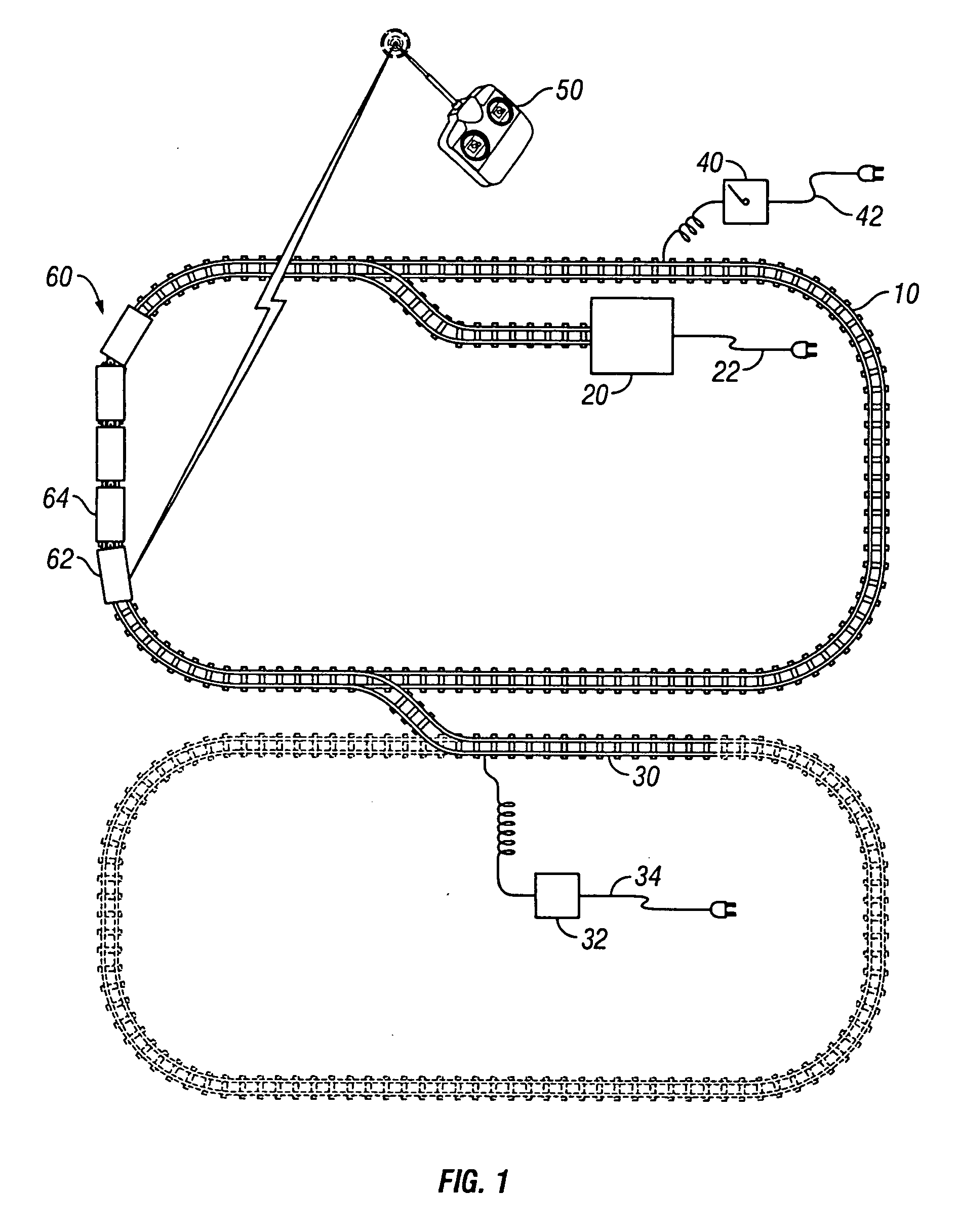

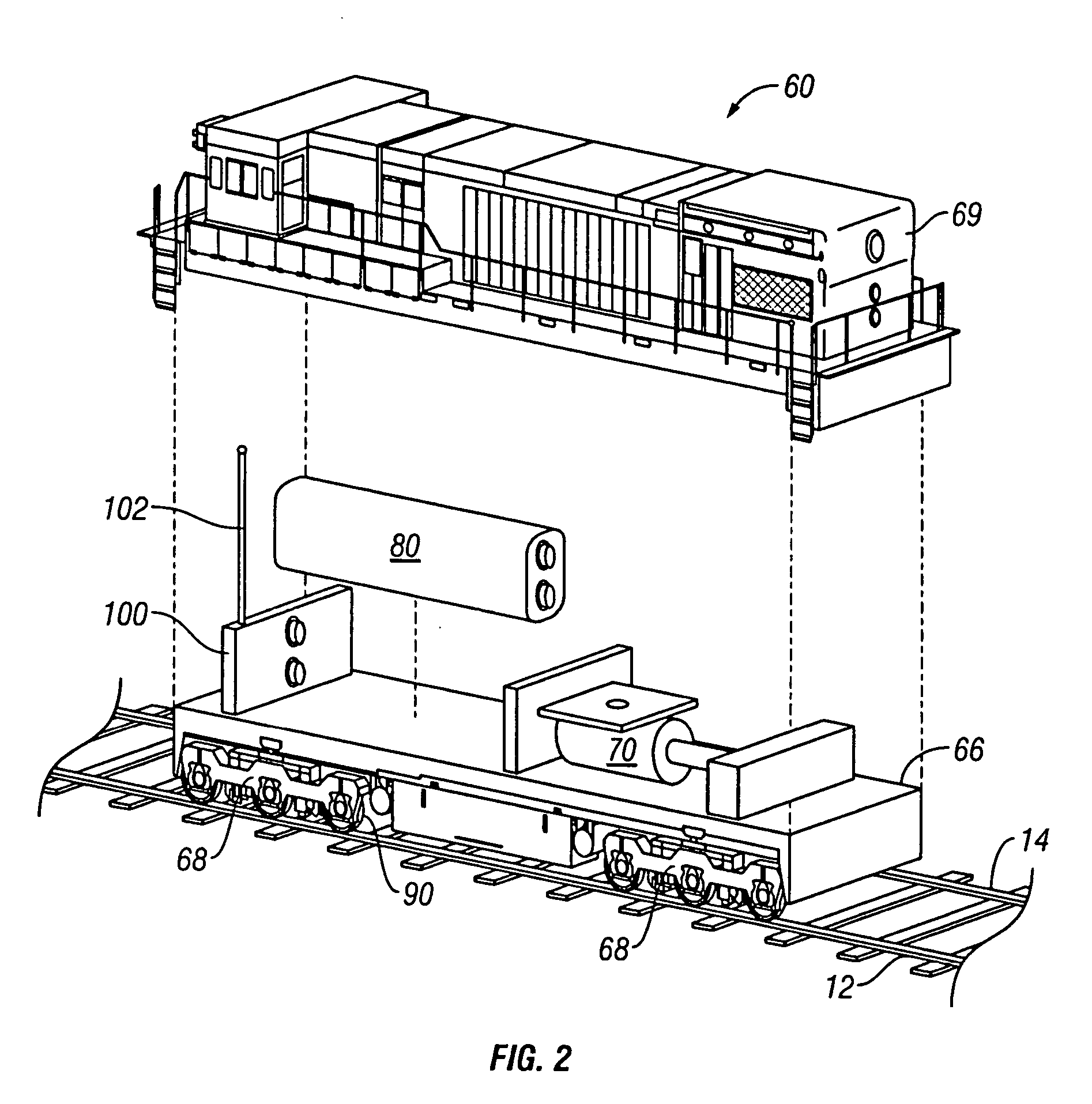

[0016]FIG. 1 schematically shows a model railroad system having a main track 10, a first charging station 20 and a second charging station 30 which comprises an electrically energizable section of track separate from the main track and a charger 32 connectable by an electric cord 34 to a conventional wall outlet. Although the main track 10 is shown in the form of a loop for simplicity, the configuration of the main track 10 can take any desired form as desired by the model railroad enthusiast. Similarly, the second charging station 30, shown in solid lines as a dead end section of track on which the locomotive can be parked for charging a rechargeable source of electrical power 80 mounted on the locomotive or on a separate car moveable with the locomotive, may also comprise a loop as shown in broken lines or any other desired configuration. Optionally, a transformer 40 which may be connected via an electrical cord 42 to a wall outlet is shown for electrically energizing the main tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com