System for loading a muzzle-loading firearm with smokeless or black powder

a muzzle-loading firearm and black powder technology, applied in the field of muzzle-loading firearms, can solve the problems of inherently dangerous carrying and handling powder in the field, muzzle-loading small arms that cannot fire, and powder could ignite and possibly injure the shooter, and achieve the effect of less maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

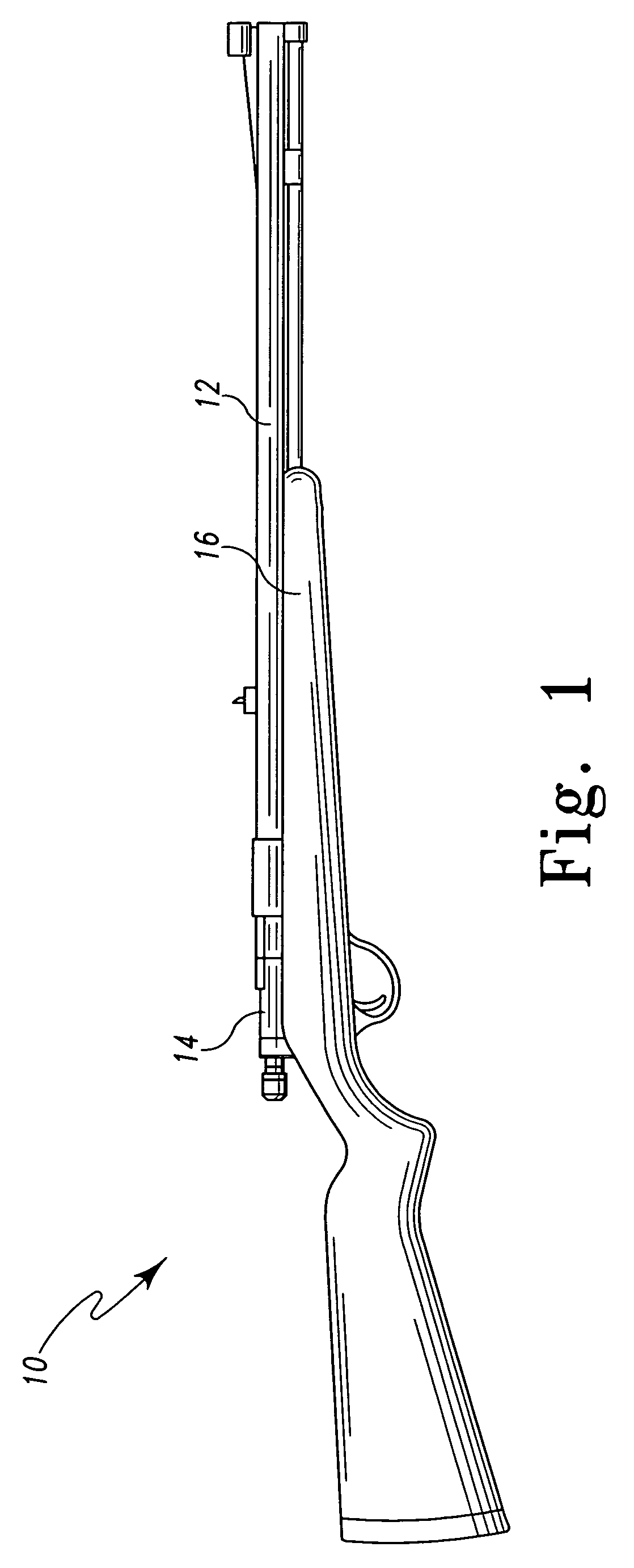

[0024] Referring to FIG. 1, an in-line muzzle-loading firearm 10 is illustrated that includes a barrel 12, a receiver 14 and a gun stock 16. The barrel 12 extends forwardly from a forward end of the receiver 14 a predetermined length. The barrel 12 and receiver 14 may be connected with the gun stock 16. Although not specifically illustrated in FIG. 1, the barrel 12 may be connected with the receiver 14 using several different connection methods or devices. For example, in some embodiments of the present invention, an outside surface of the breech end of the barrel 12 may include threads and an inside surface of the receiver 14 may include matching threads that allow the barrel 12 to be screwed into the receiver 14. The depiction of the in-line muzzle-loading firearm 10 illustrated in FIG. 1 is for illustrative purposes only and should not be construed as a limitation of the present invention.

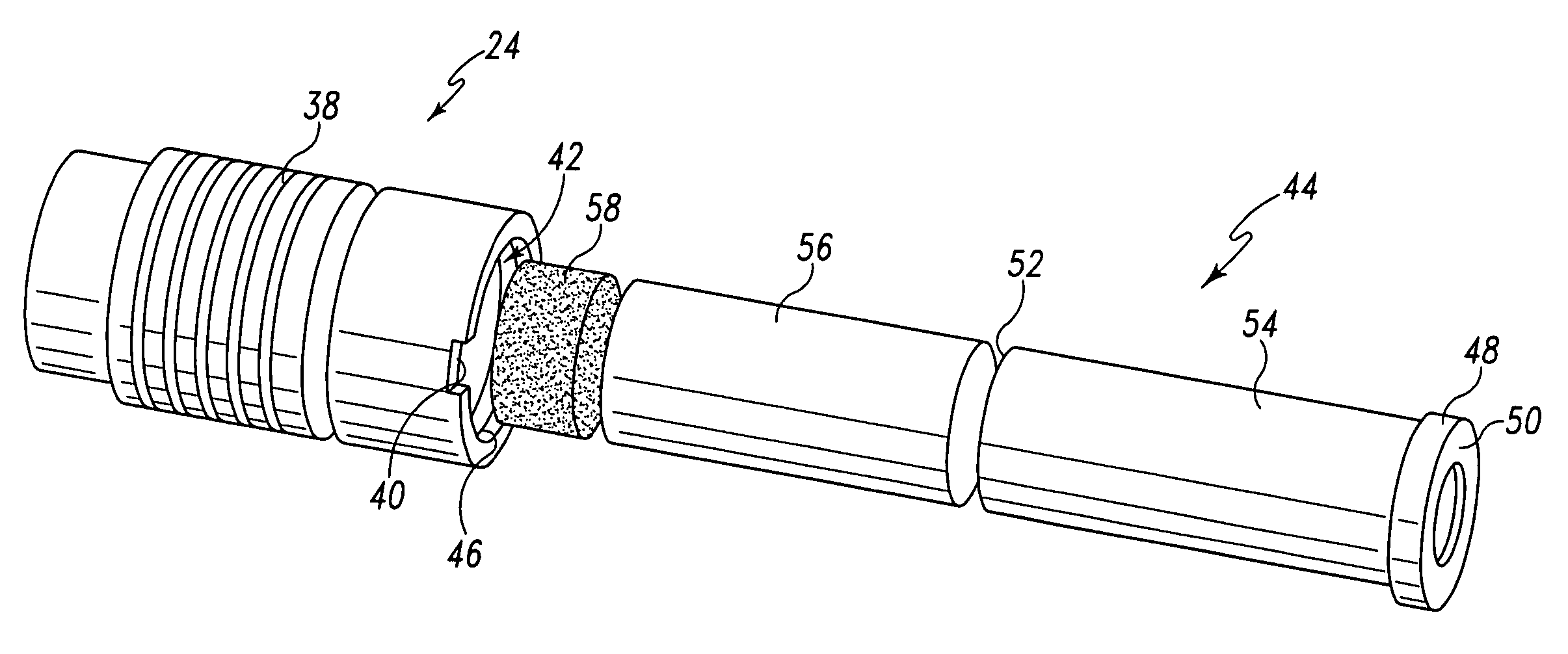

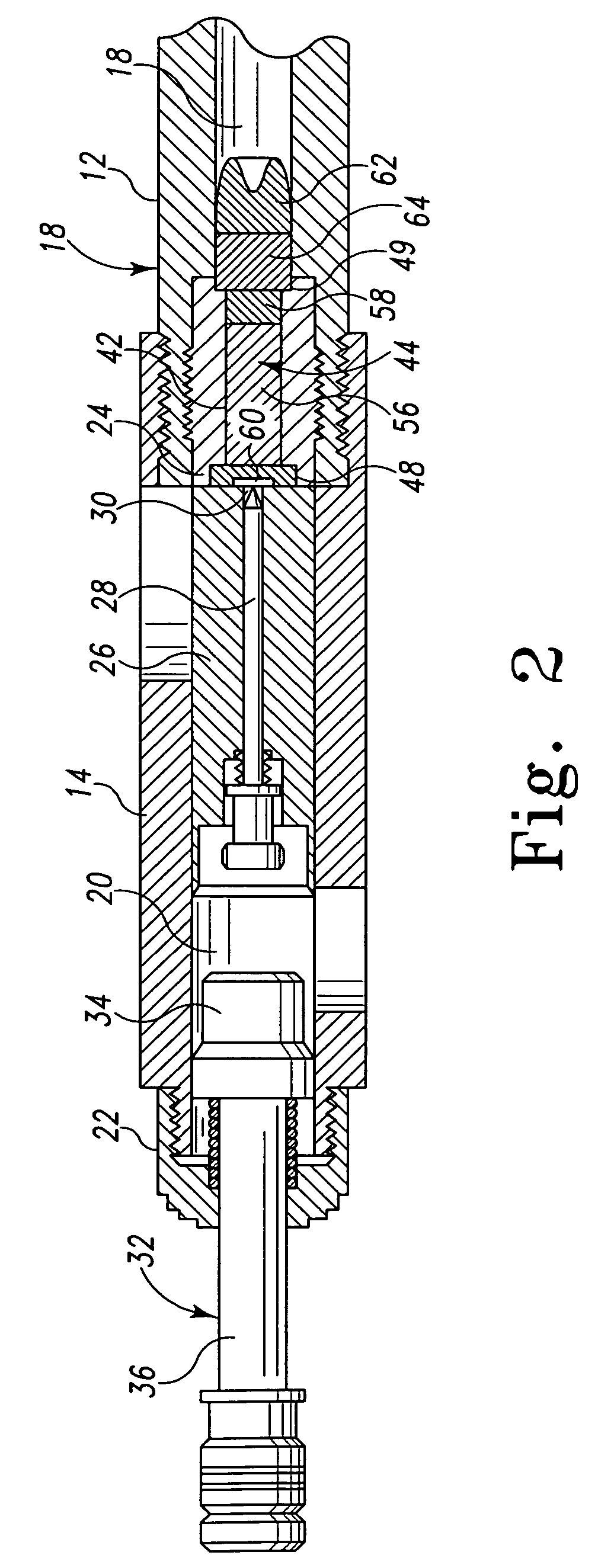

[0025] Referring to FIG. 2, the in-line muzzle-loading firearm 10 may include a breech 18 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com