Sorting recycle materials with automatically adjustable separator using upstream feedback

a technology of automatic adjustment and separator, which is applied in the direction of gas current separation, sustainable waste treatment, instruments, etc., can solve the problems of only good setting for a matter, low efficiency of separator, and limited mrf operators' ability to determine the optimal operating parameters of these new screens. achieve the effect of improving the efficiency of separator operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The Overall MRF System

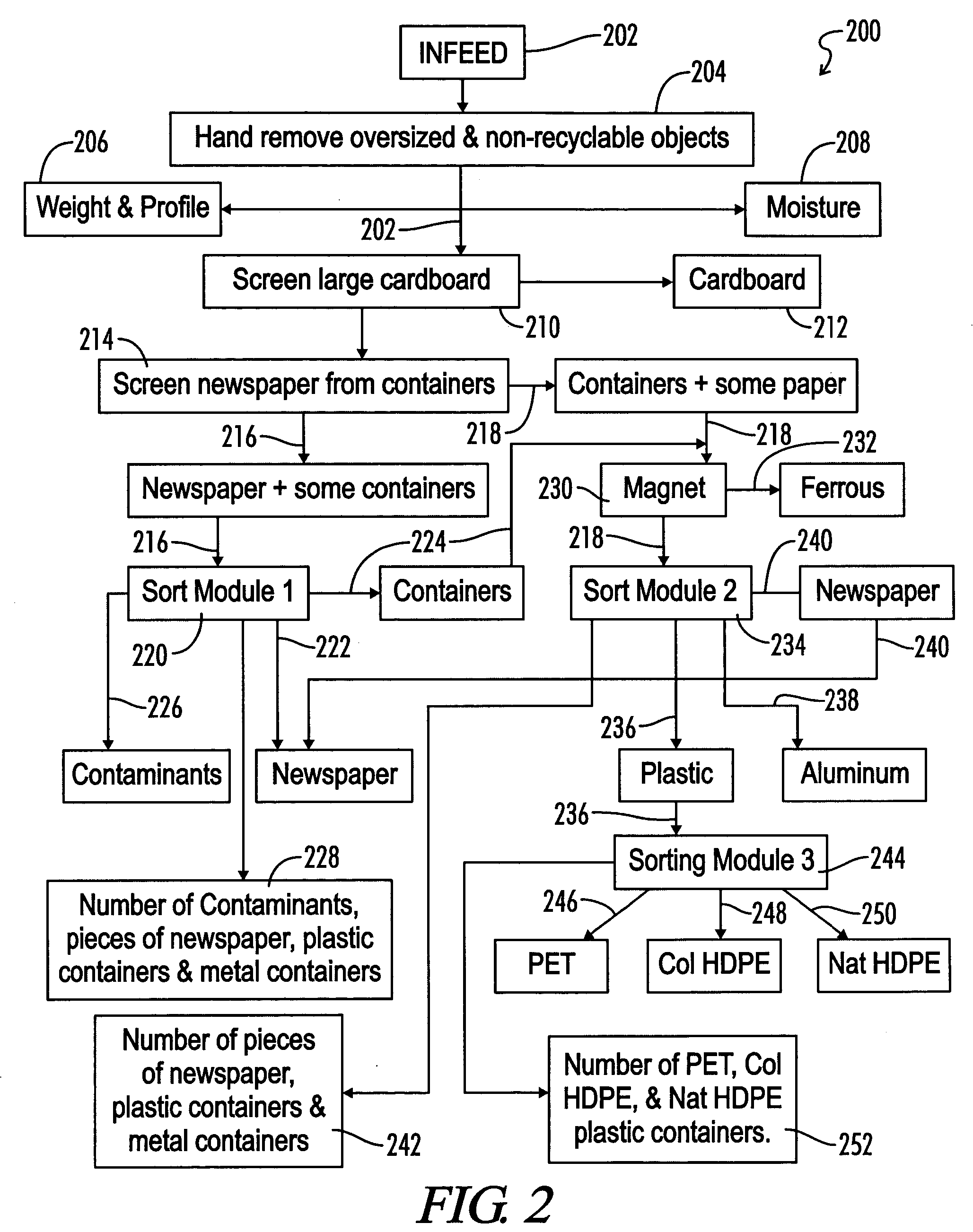

[0045] Referring now to FIG. 2, the Materials Recovery Facility (MRF) of the present invention is shown and generally designated by the numeral 200. FIG. 2 schematically illustrates the major components of and the material flow through the Materials Recovery Facility 200.

[0046] An input waste material stream 202 enters the MRF 200. As indicated at block 204, oversized and non-recyclable objects are removed by hand.

[0047] A weight and profile sensor 206 and a moisture sensor 208 are provided to monitor the weight, the height profile and the moisture content of the input material stream 202.

[0048] As indicated at block 210 a large article screening device 210 may be used to separate large cardboard items which go to a cardboard destination 212.

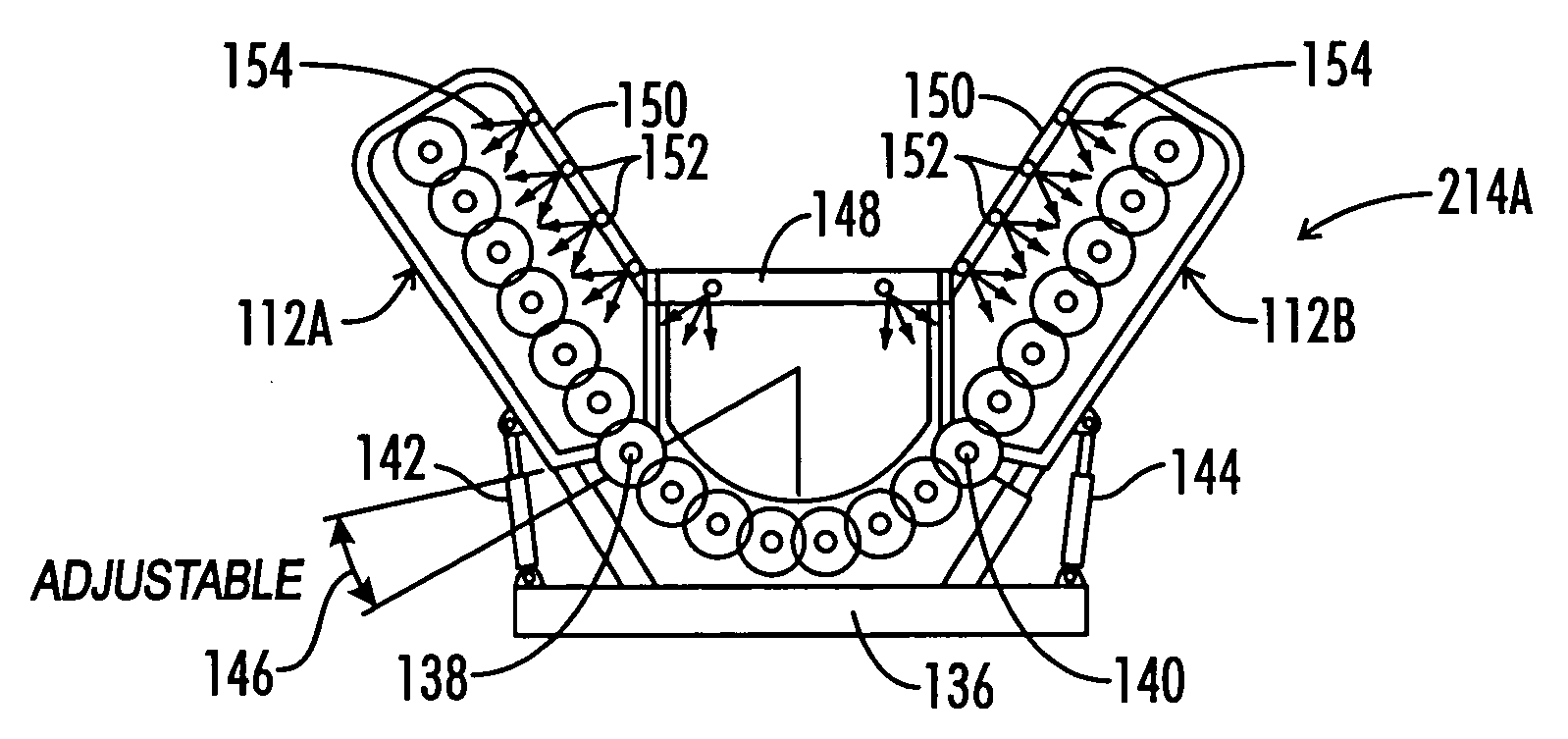

[0049] The bulk of the material which is typically made up of containers of various types and newspaper goes to a mechanical screening device 214 which may, for example, be an adjustable angle trough shape screening d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com