Capsule filling machine

a filling machine and capsule technology, applied in the field of capsule filling machines, can solve the problem that the pin cannot exert sufficient pick up force on the micro-tablet, and achieve the effect of high precision dosing and production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

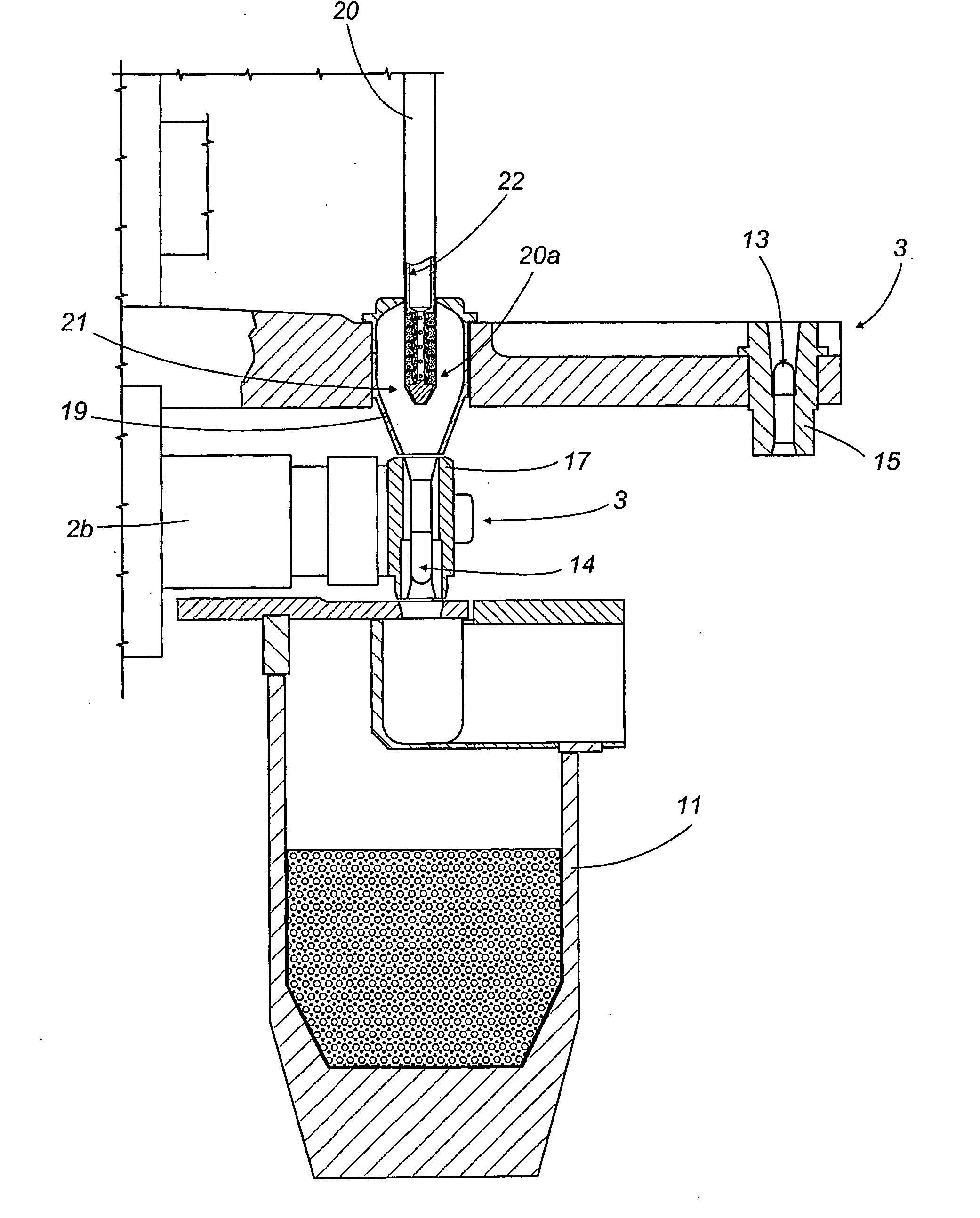

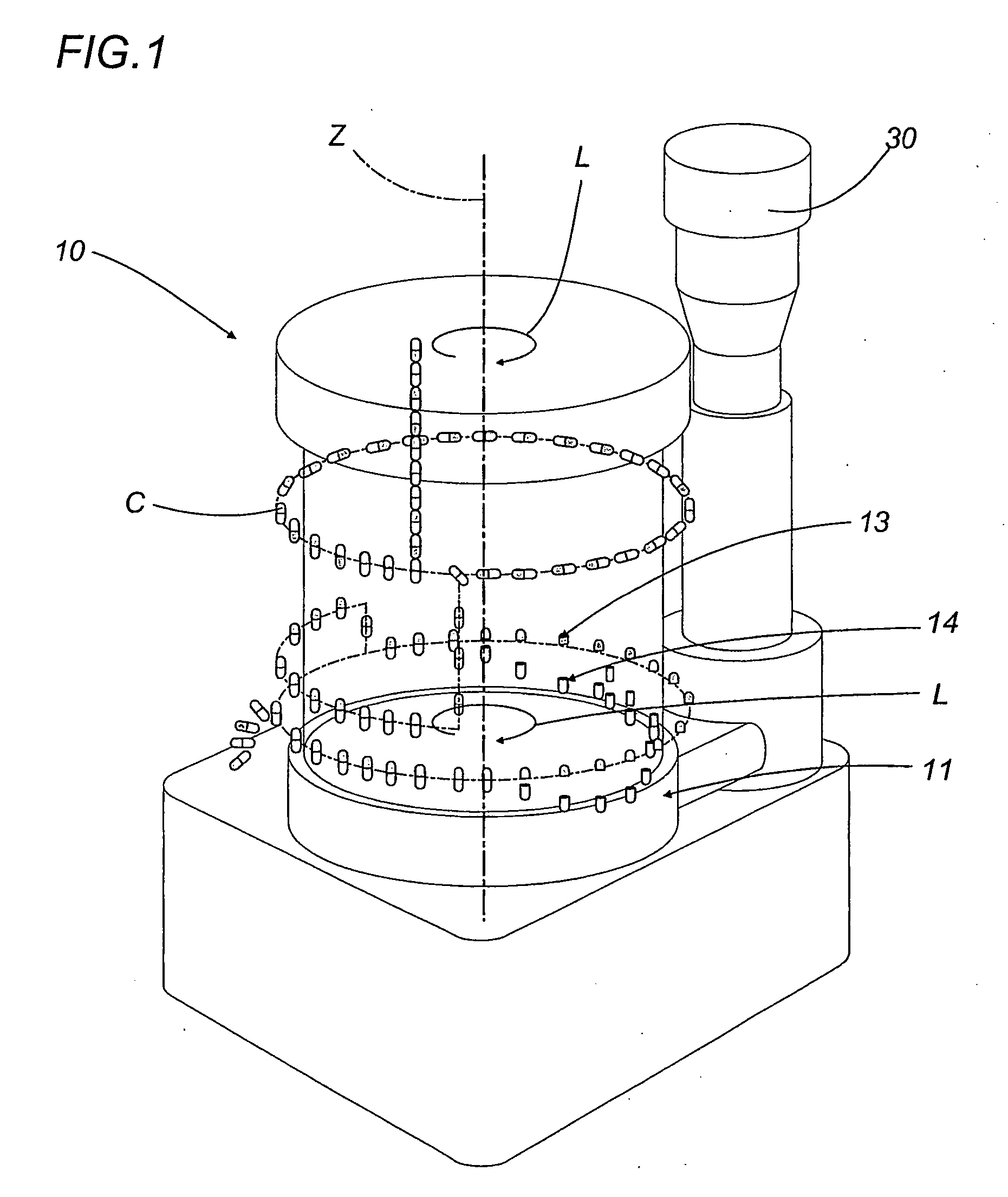

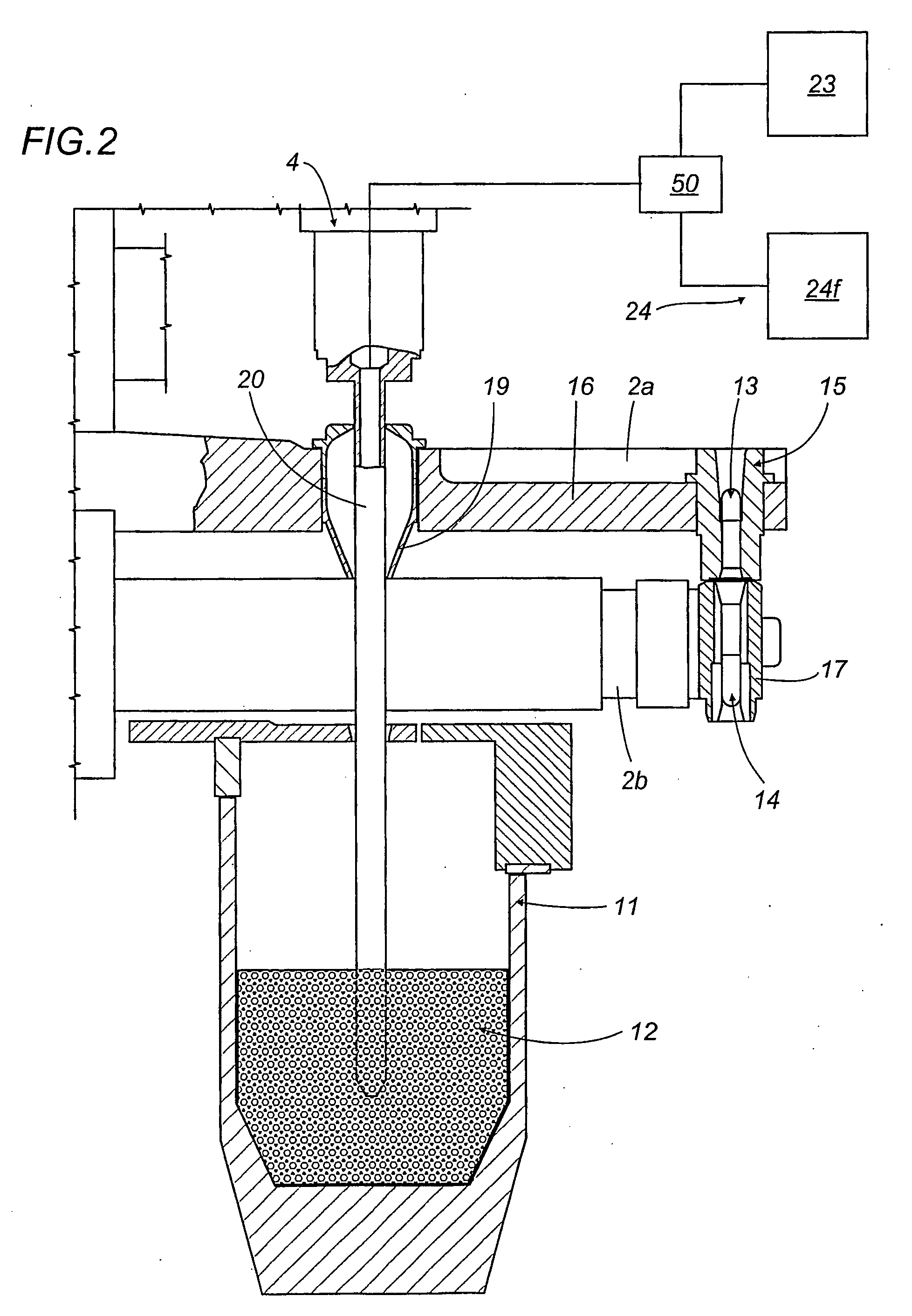

[0019] With reference to FIG. 1, the capsule filling machine disclosed, labelled 10 as a whole, is used for filling capsules C of the known type with a capsule lid and a capsule body, labelled 13 and 14 respectively, with given quantities of particles 12 of pharmaceutical material, specifically pharmaceutical micro-tables 12 or pellets.

[0020] As illustrated in FIGS. 1, 2 and 3, the capsule filling machine 10 comprises a first carrousel 2 rotating about a vertical axis Z in the direction indicated by the arrow L and having radial arms 2a, 2b supporting a plurality of slide units 3 for picking up capsule bodies 14 of capsules C and moving them in a horizontal direction, and a tank 11 with a known, substantially toroidal shape, located at the base of the capsule filling machine 10 and designed to hold a mass of micro-tablets 12 supplied from a feed hopper 30.

[0021] The machine 10 also comprises a second carrousel 4 (FIG. 2), also rotating about the vertical axis Z, again in the direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com