Components for use in large-scale concrete slab constructions

a technology of large-scale concrete and components, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of large, unfavorable construction safety and convenience, and large stirrups, and achieve the effect of sufficient internal tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Structural Stirrups

[0035] Structural stirrups, also known as structural spacers because they space apart bars and void formers (or other formwork), provide extra points for locating lengths of reinforcing iron within a channel so that the resulting rib will have a structurally useful degree of strength. Examples are shown as FIGS. 4, 6, 7 and 8. They include bends to locate bars of reinforcing iron at a range of depths. The structural stirrup of FIG. 4 includes downward-directed bends at 409, 401 and 415 that can hold bars by gravity alone, avoiding the labour costs of placing wire ties. Extra bars could be tied in at 407 and 408, providing either a three-bar reinforced rib, or a five-bar reinforced rib.

[0036]FIG. 4 shows a typical structural component, according to the invention, for use in reinforced concrete structures. (Dimensions are given by way of illustration only). This component is made of 6.4 mm diameter steel rod, formed by bending in a numerically controlled bending a...

example 2

Cage Constructions, Assembled on the Site

[0050] A further development of the present invention that is intended for significantly greater loadings is partly based on a non-structural stirrup as per FIG. 5a, but with additional parts. Further, it resembles a cage structure, but one that is preferably assembled on site. Some functions of a simple stirrup, such as determination of the channel size are retained. By way of comparison, we first describe a prior-art four-bar cage structure illustrated as FIG. 5b. In this cage, which has an indefinite length, four bars such as 502, 504, 505 and 506 are tied to a series of bent reinforcing iron bars 503 which serves to maintain the bars in a spaced-apart configuration after embedment in concrete, so that the resulting reinforcement has greater strength to resist torques. Larger cages would use stouter rods and have more of them.

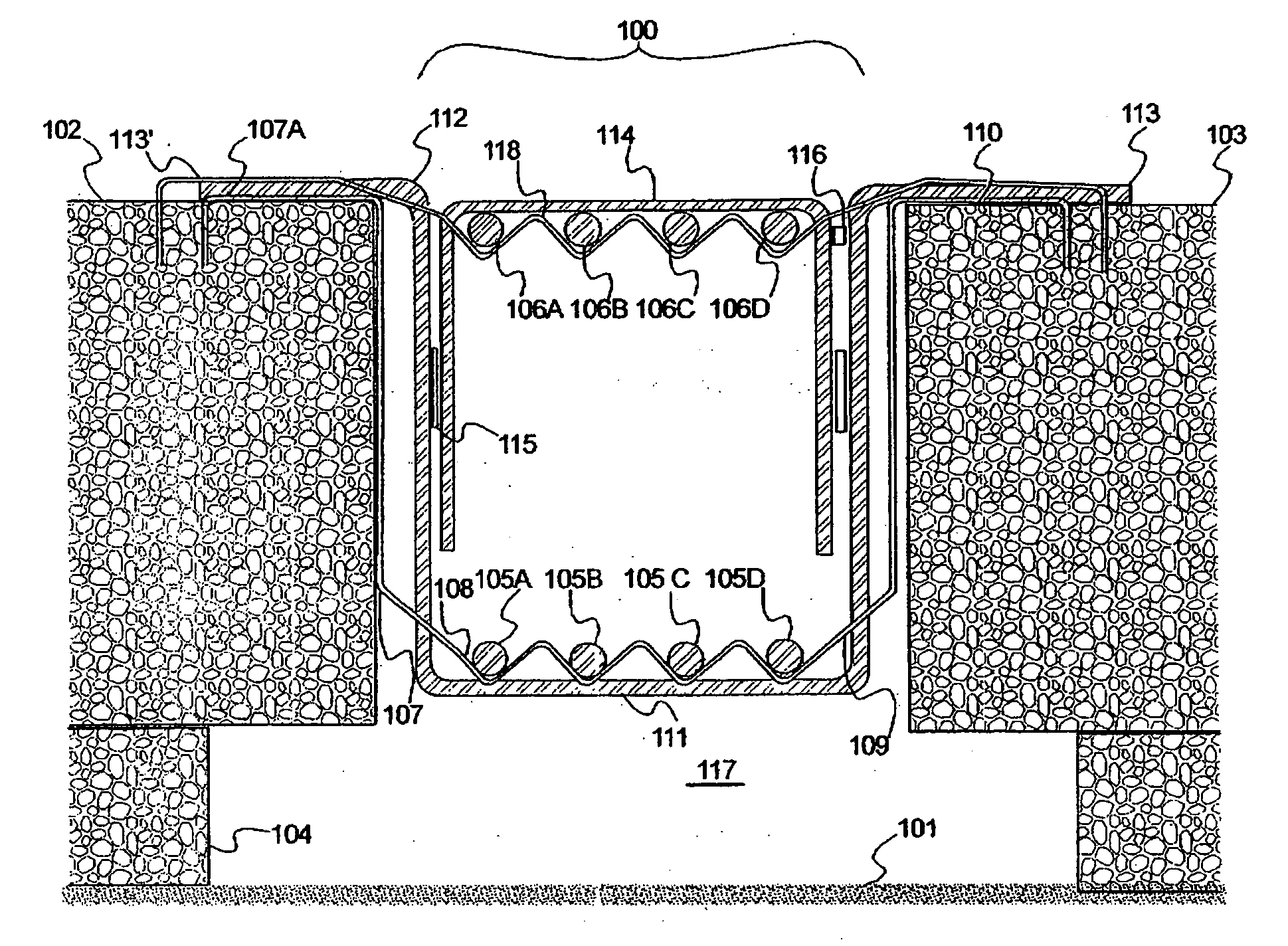

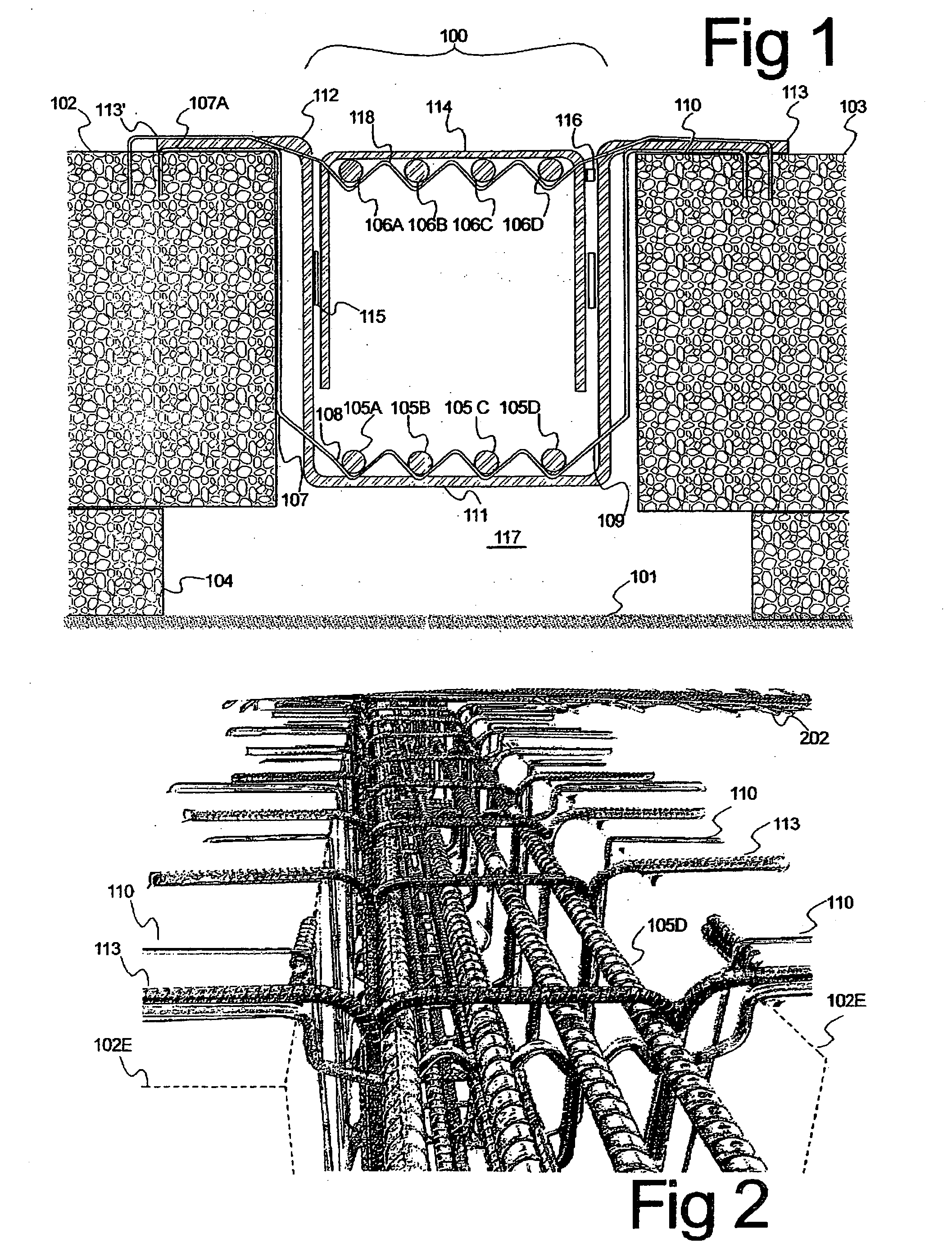

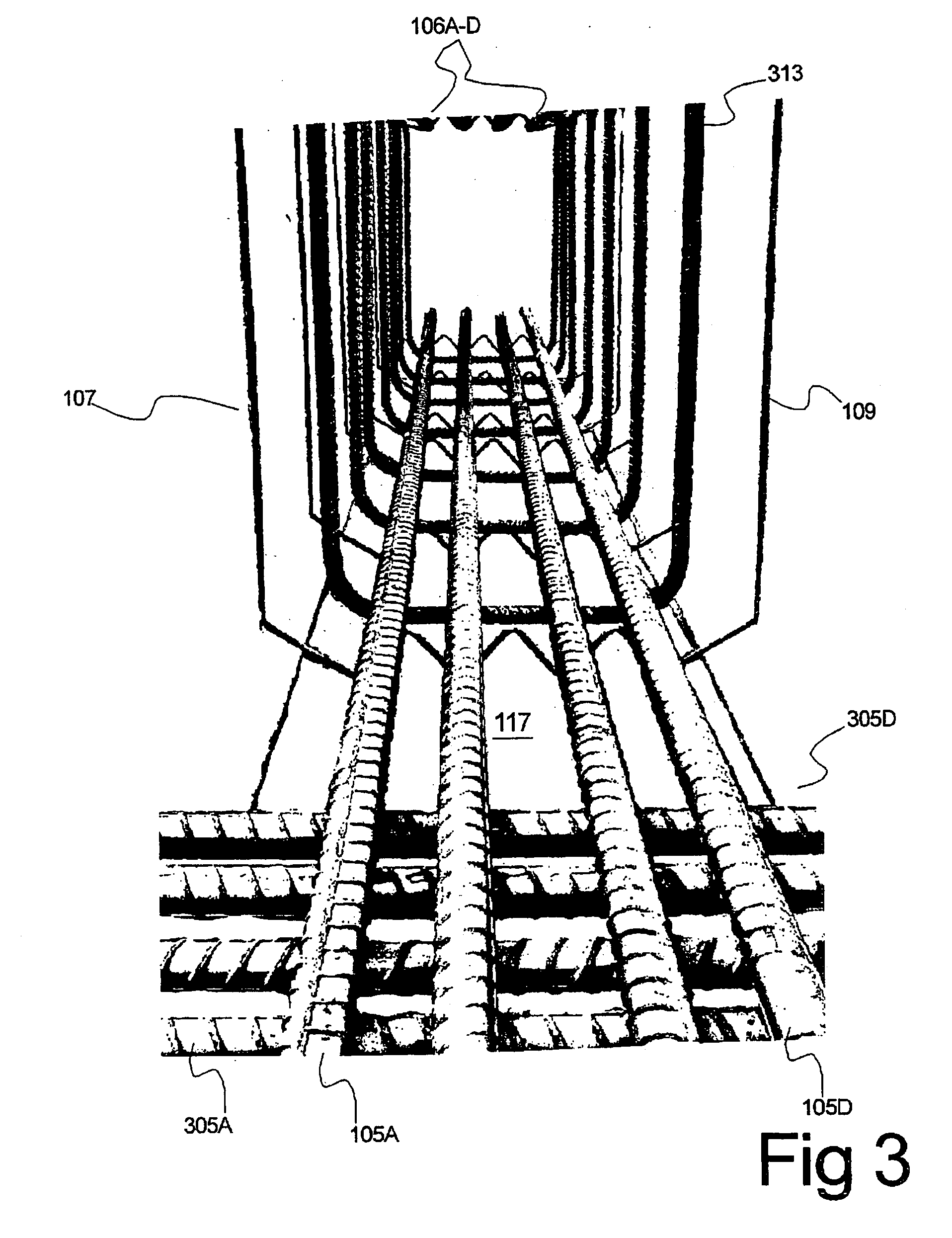

[0051] This description and these drawings are based on a specific prototype, show an eight-bar cage, and refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com