Electrical installation comprising a decompression channel

a decompression channel and electric installation technology, applied in the direction of switchgear arrangement, non-enclosed substation, substation, etc., can solve the problem that it is not possible for hot gases or pressure waves to enter the other functional modules, and neither the installation nor the person is harmed or damaged in any way, and achieves the effect of reliable dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

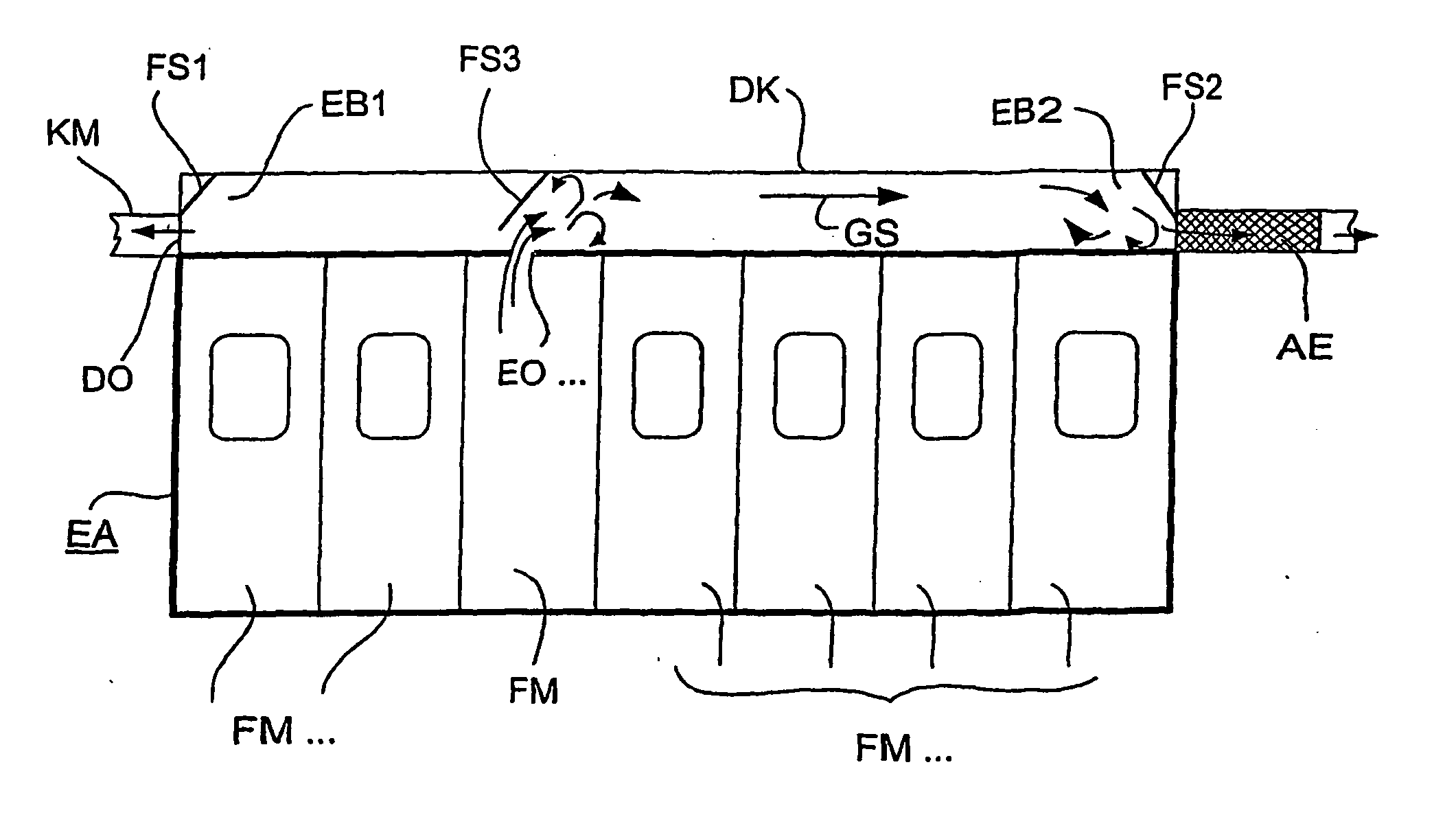

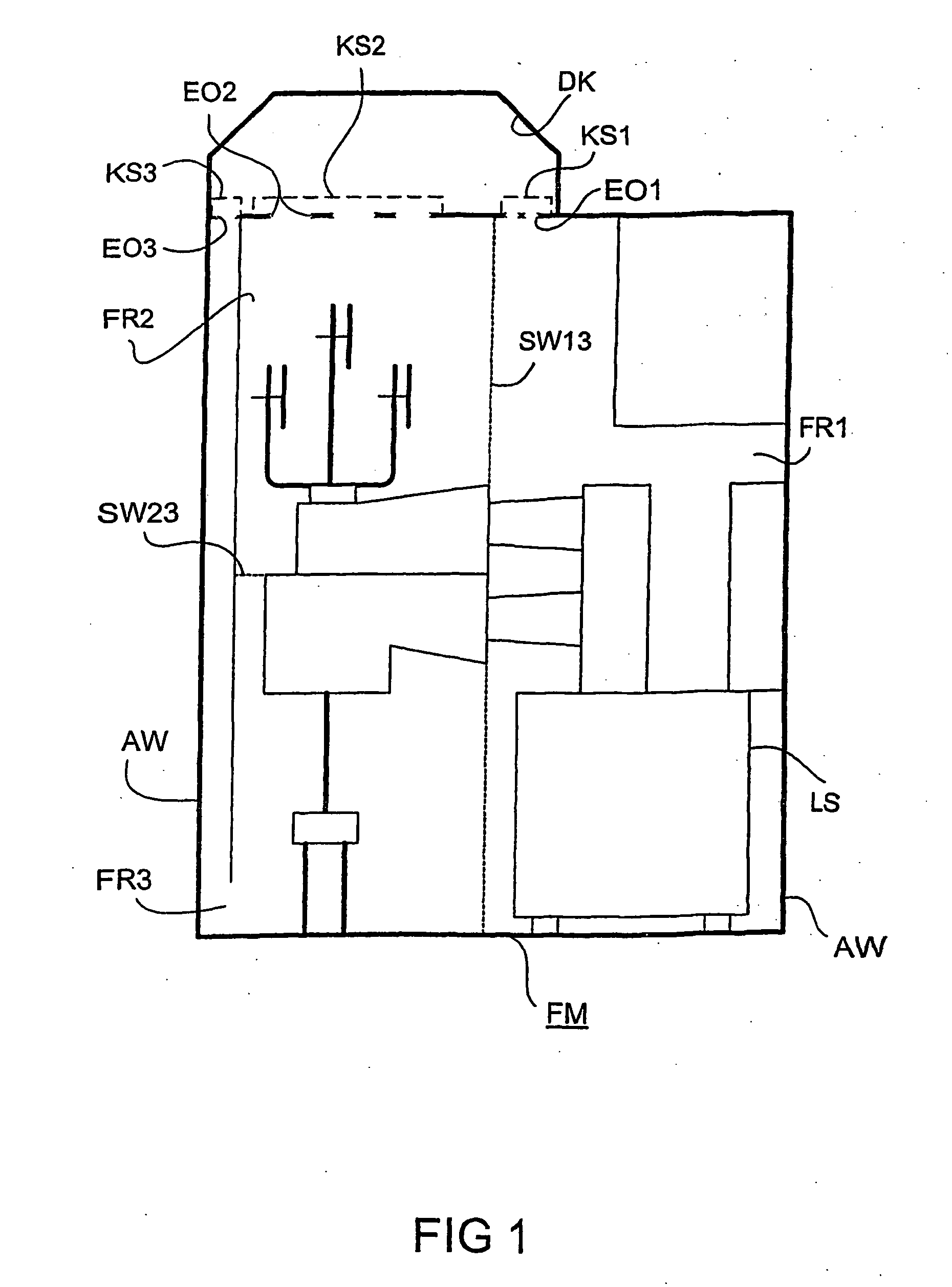

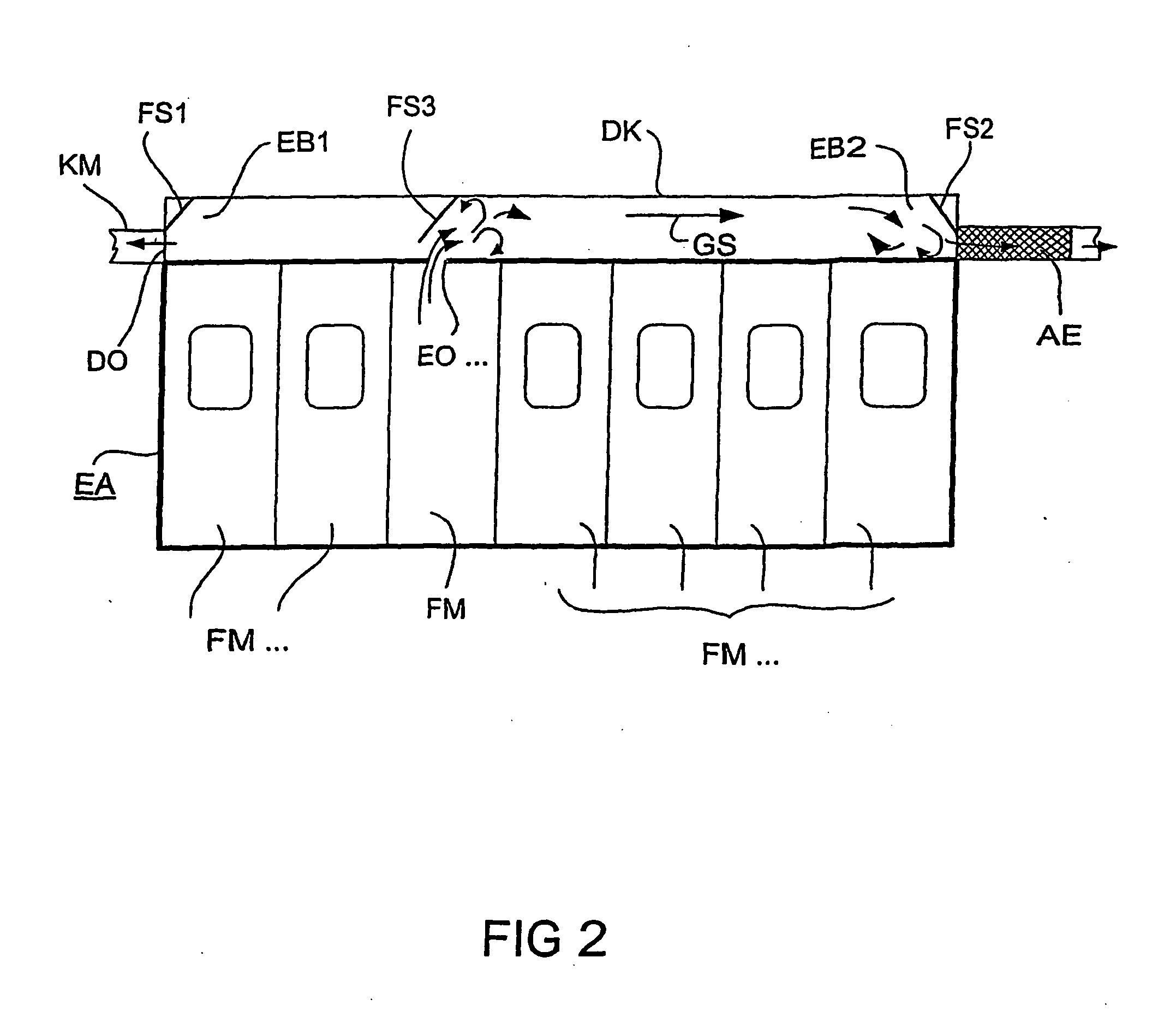

[0022] The functional module FM shown in FIG. 1 is divided up into a plurality of functional compartments FR 1, 2, 3. These compartments are separated from one another in a gas-permeable manner by partition walls SW 13, 23. In other designs, the partition walls SW . . . can also separate the individual functional compartments FR . . . from one another in a pressure-tight manner. The individual functional compartments FR . . . may be, for example, switching module compartments FR 1 having power breakers LS, connection compartments FR 3 or busbar compartments FR 2. The outer walls AW of the functional module FM shown are closed off in a pressure-tight manner both from the area surrounding the installation and from any further functional modules FM . . . which may be adjacent. In the exemplary embodiment shown, the inlet openings EO 1, 2, 3 to the pressure release duct DK are on the top face of the functional module FM. In this case, each functional compartment FR 1, 2, 3 has its own c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com