Pneumatic vehicle tyre

A technology for pneumatic tires, vehicles, applied in vehicle parts, tire parts, tire tread/tread pattern, etc., to solve block cracks, high pull-out force, cracks at the bottom of the groove and/or block protrusions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

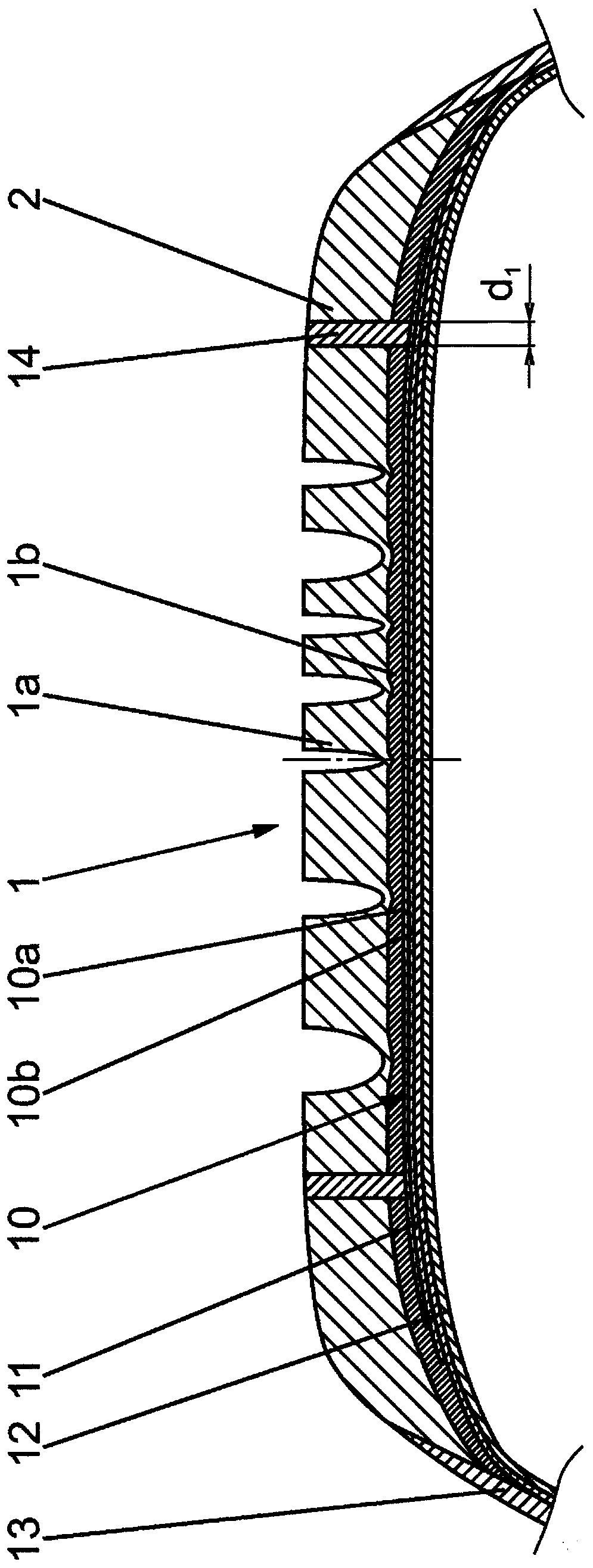

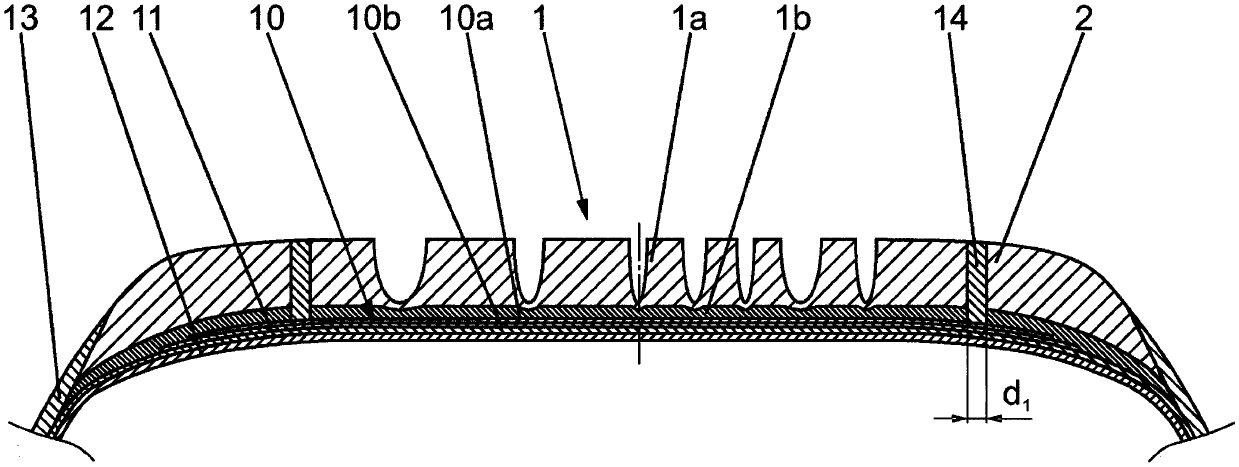

[0017] The pneumatic tire for vehicles embodied according to the invention is in particular a winter tire of the radial type for passenger cars, vans or light trucks. Hereinafter, the present invention is explained by way of example based on a winter tire provided for passenger cars.

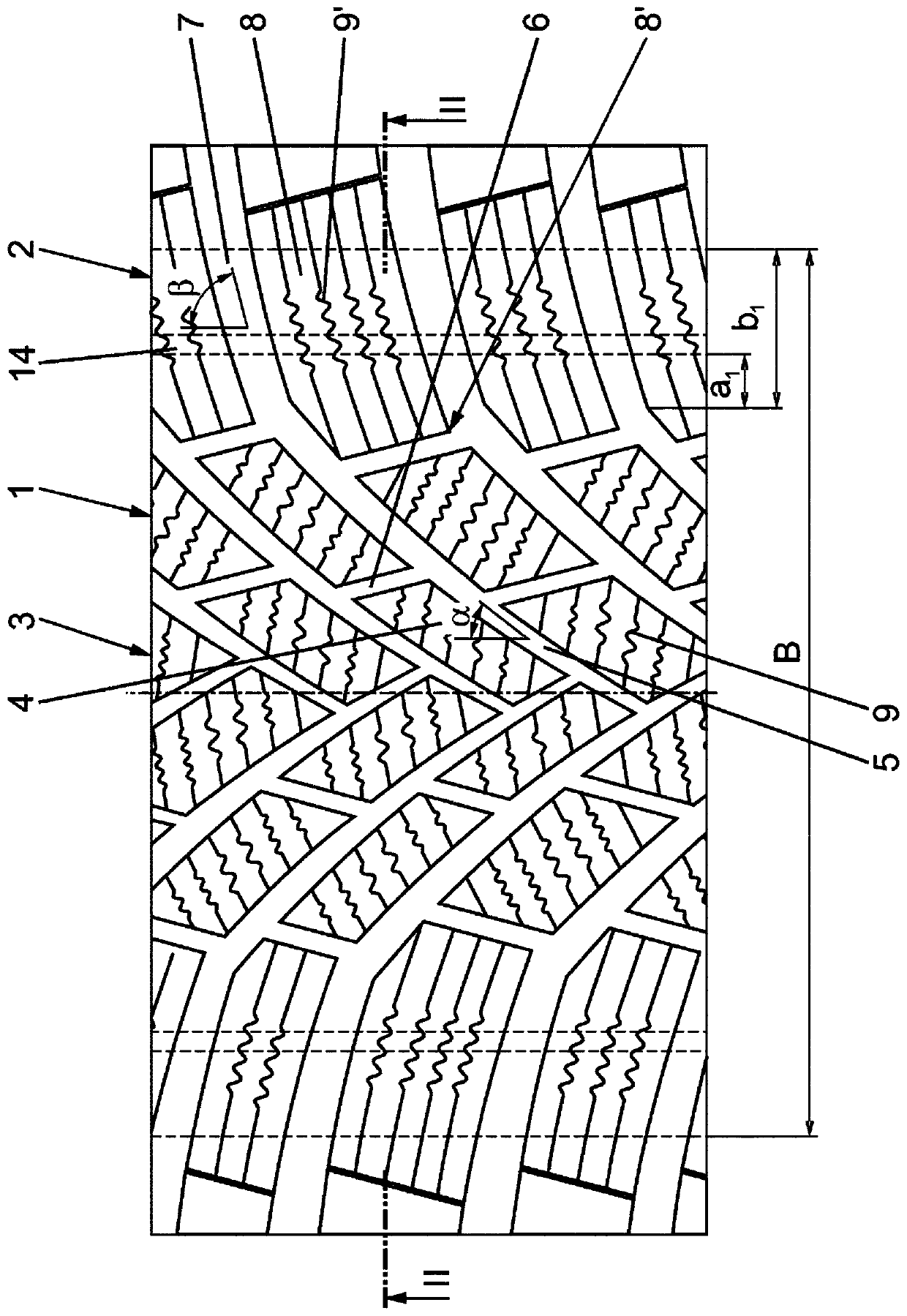

[0018] figure 1 The tread 1 shown is implemented in a directional manner and has a contact patch width B corresponding to the width of the resting footprint determined according to the E.T.R.T.O. The tread 1 has two shoulder-side block rows 2 and between the two shoulder-side block rows a central tread region 3 constructed of a plurality of blocks 4 .

[0019] In the embodiment variant shown, the central tread region 3 is provided with oblique sipe 5 and short sipe 6 extending between adjacent oblique sipe 5 in the circumferential direction, wherein , the oblique grooves 5 and the short grooves 6 together define the blocks 4 . The oblique grooves 5 run at an angle α of 30° to 60°, in particul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com