Rapidly assembled finishing-free modular house with single-boards

a modular house and assembly technology, applied in the field of housing technologies, can solve the problems of not only long construction time, high cost, and large amount of manpower, and the houses built with these types of constructions cannot be reused, and cannot be removed and re-assembled, so as to achieve convenient and quick construction, easy transportation, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

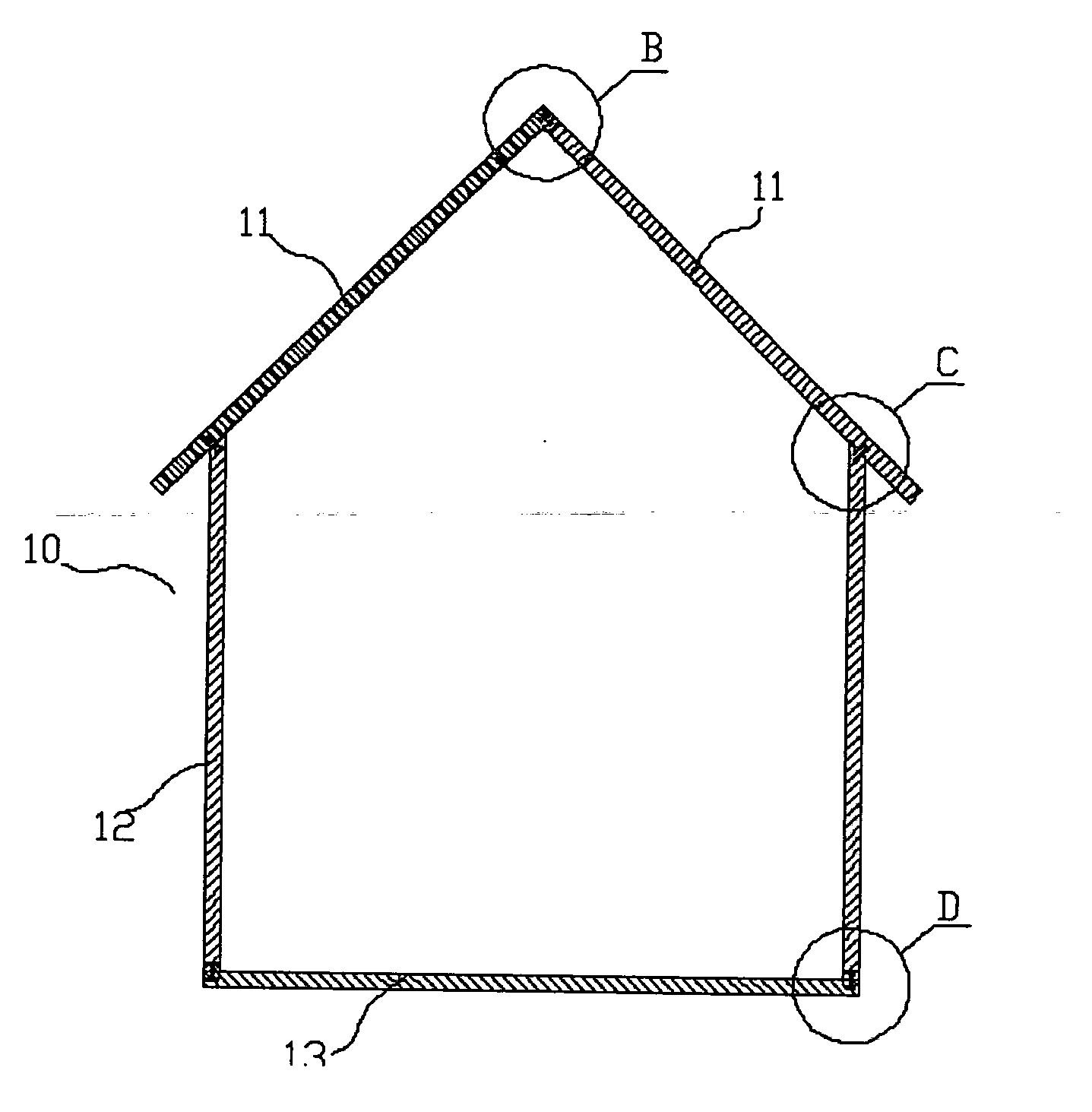

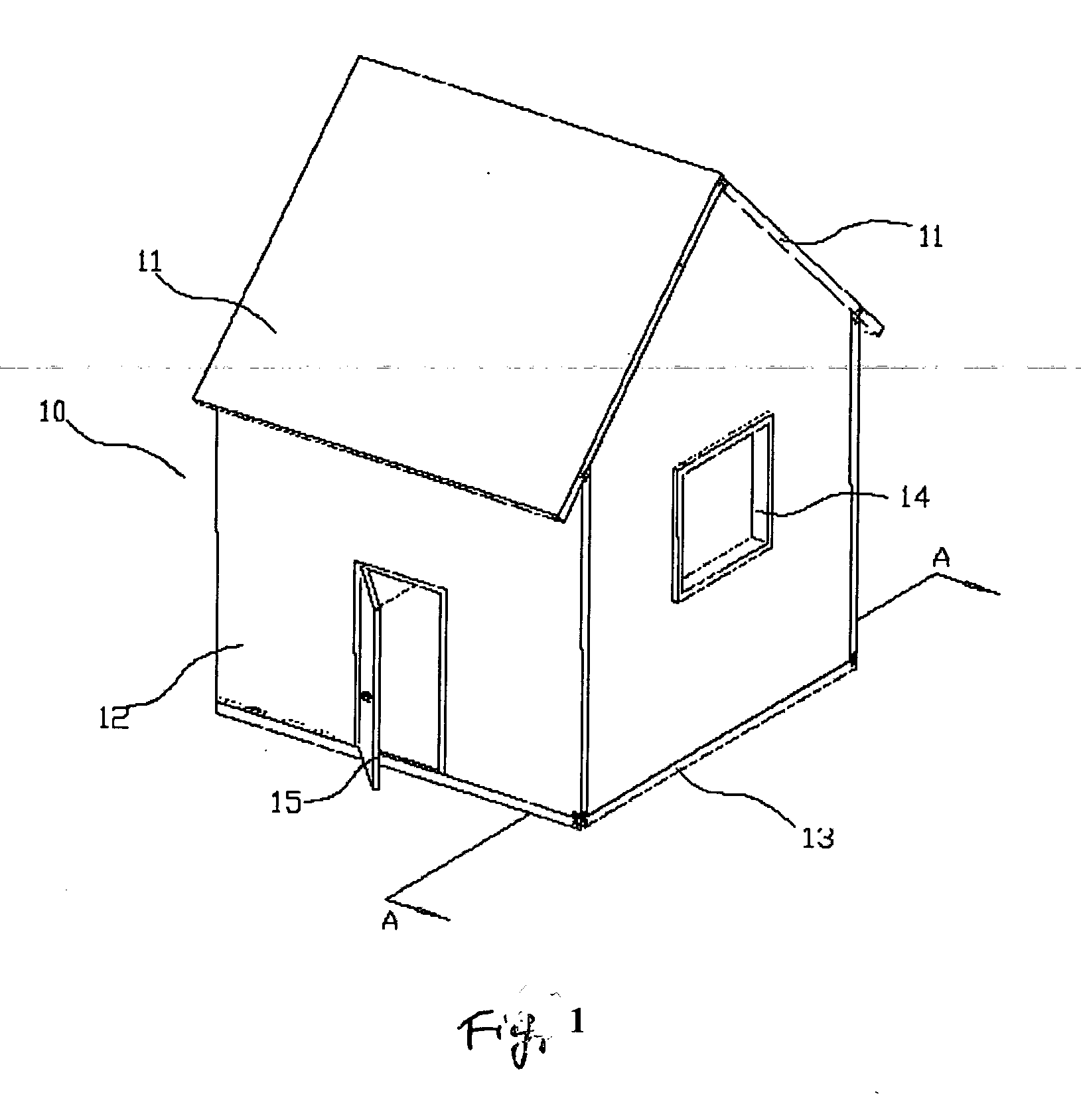

[0019] FIGS. 1 to 7 illustrate the embodiment 1 of this invention. In this embodiment, a house 10 comprises top 11, side 12 and base 13. Each panel of top 11, side 12 and base 13 of a house 10 is a single board 1 that has a groove 5. The boards 1 of top 11, side 12 and base 13 are firmly embedded together via channel adapters 2. In this embodiment, the top is in an inverted “V” shape that is formed by two boards 1. The side 12 is surrounded with four boards 1 that are assembled in sequence. The base 13 uses a single board 1.

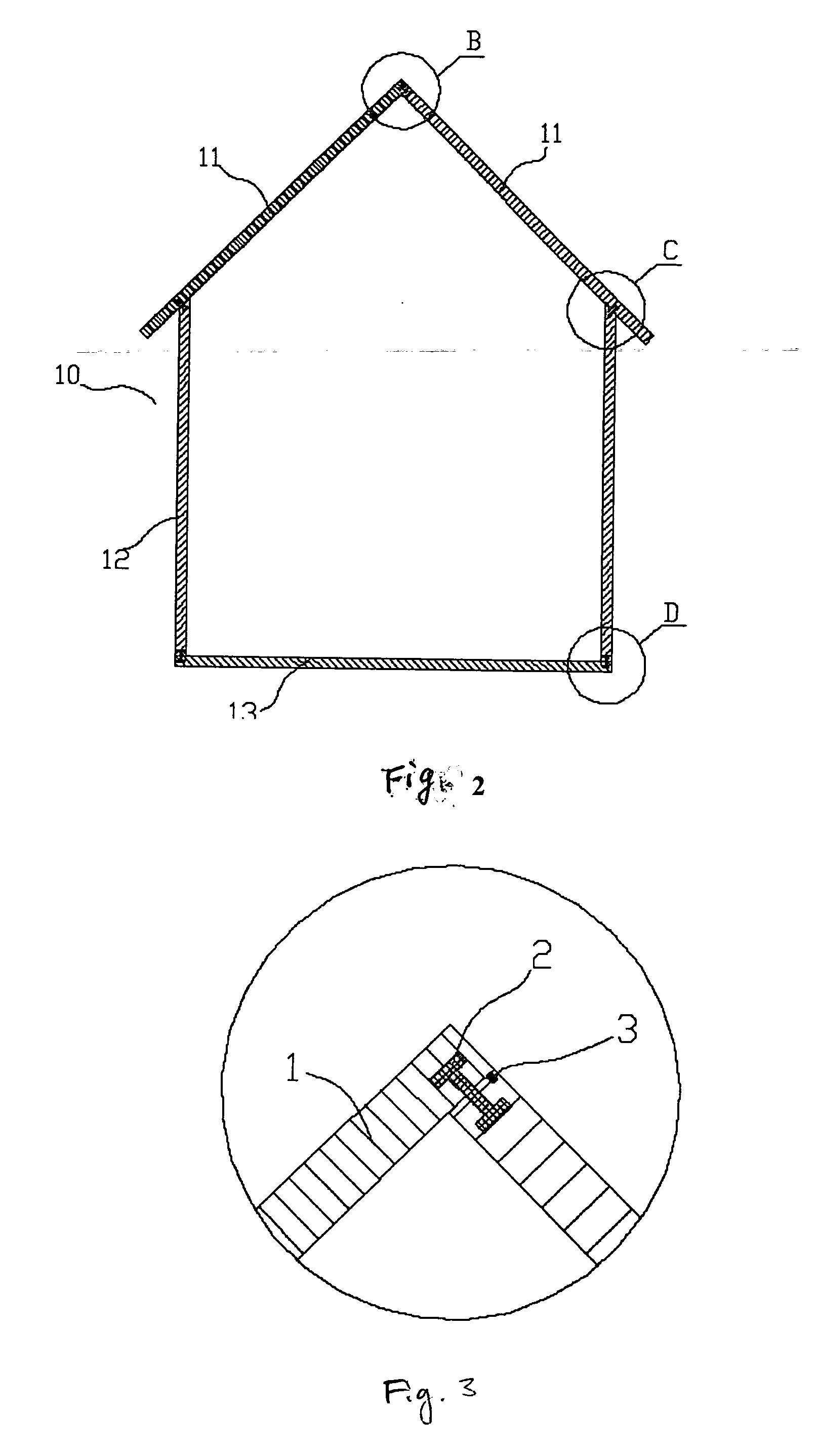

[0020] The channel adapter 2 used in house 10 is in “H” shape. The two side edges of a channel adapter 2 are embedded respectively in the two adjacent boards 1 that have “T” shape grooves 5. In other words, the connecting surface of each board has a “T” shape groove 5. The two edges of an H-channel adapter 2 are inserted separately into the groove 5 of each board 1 to tighten and fix two adjacent boards.

[0021] Two boards 1 can be connected vertically as shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com