Double-layer stranded all-dry type optical cable

A fully dry, double-layer technology, applied in the field of communication optical cables, can solve the problems of reducing the water resistance of optical cables, the loss of filling grease, and reducing the splicing efficiency, so as to improve the construction splicing efficiency, reduce the weight, and increase the excess length of optical fibers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

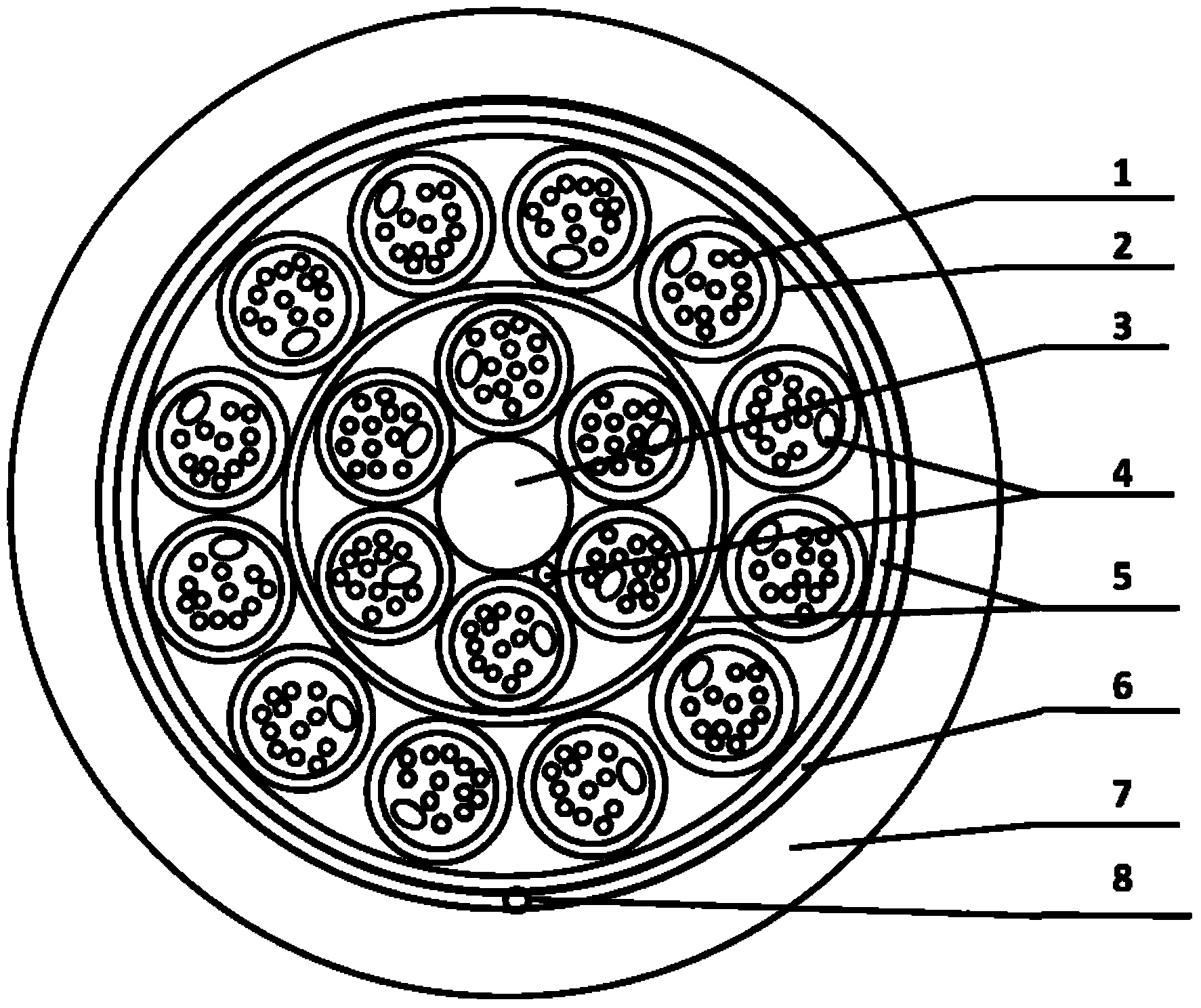

[0039] Example 1: 1+6+12 structure

[0040] see figure 1 As shown, the double-layer stranded fully dry optical cable in Embodiment 1 includes a central strengthening component, a double-layer stranded cable core, a water blocking tape 5, a reinforcing yarn 6 and an outer sheath layer 7, and the central strengthening component includes a strengthening core 3, The reinforcing core 3 is made of glass fiber reinforced plastic rod GFRP. The outer surface of the central reinforcing component is helically wrapped with a water-blocking yarn 4 with a linear density of 3000dtex. The stranded cable core is composed of two layers of loose tubes inside and outside by SZ twisting: 6 loose tubes 2 in the inner layer, 12 loose tubes 2 in the outer layer, and the loose tubes 2 are all dry loose tubes, made of PBT Each loose tube 2 contains 12 optical fibers 1 and 1 water-blocking yarn 4 with a linear density of 1000dtex, and does not contain ointment; the inner layer of 6 loose tubes 2 is wou...

Embodiment 2

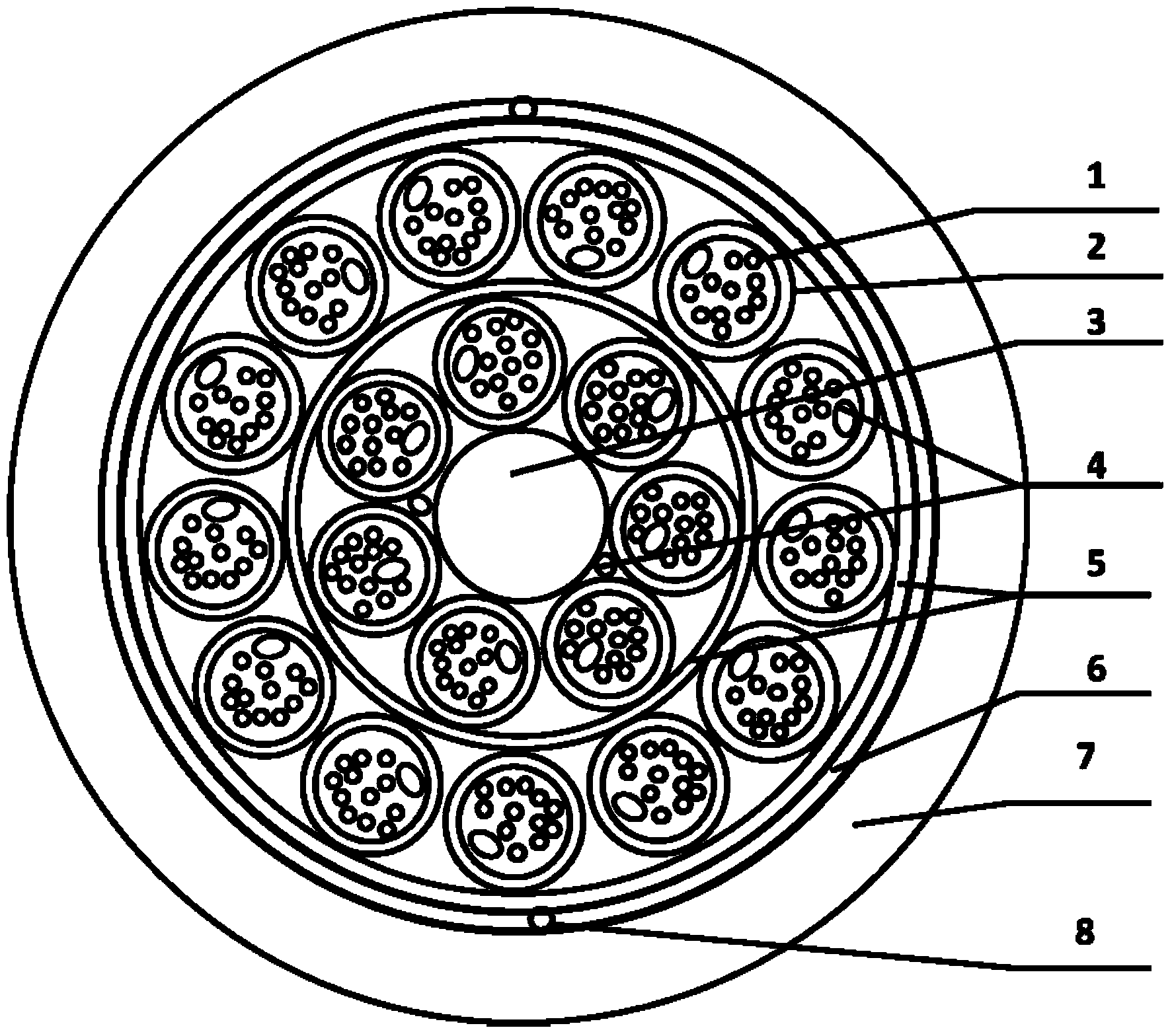

[0041] Example 2: 1+7+13 structure

[0042] see figure 2As shown, the double-layer stranded fully dry optical cable in Embodiment 2 includes a central strengthening component, a double-layer stranded cable core, a water blocking tape 5, a reinforcing yarn 6 and an outer sheath layer 7, and the central strengthening component includes a strengthening core 3, The reinforcement core 3 is made of aramid fiber reinforced plastic rod KFRP. The outer surface of the central reinforcement component is spirally wrapped with two water-blocking yarns 4 with a linear density of 4000dtex. The central reinforcement component is equipped with a double-layer twisted cable core. The layer stranded cable core is composed of two layers of loose tubes inside and outside by SZ stranding: 7 loose tubes 2 in the inner layer, 13 loose tubes 2 in the outer layer, and the loose tubes 2 are all dry loose tubes. Made of non-toxic polypropylene, each loose tube 2 contains 12 optical fibers 1 and 1 water-...

Embodiment 3

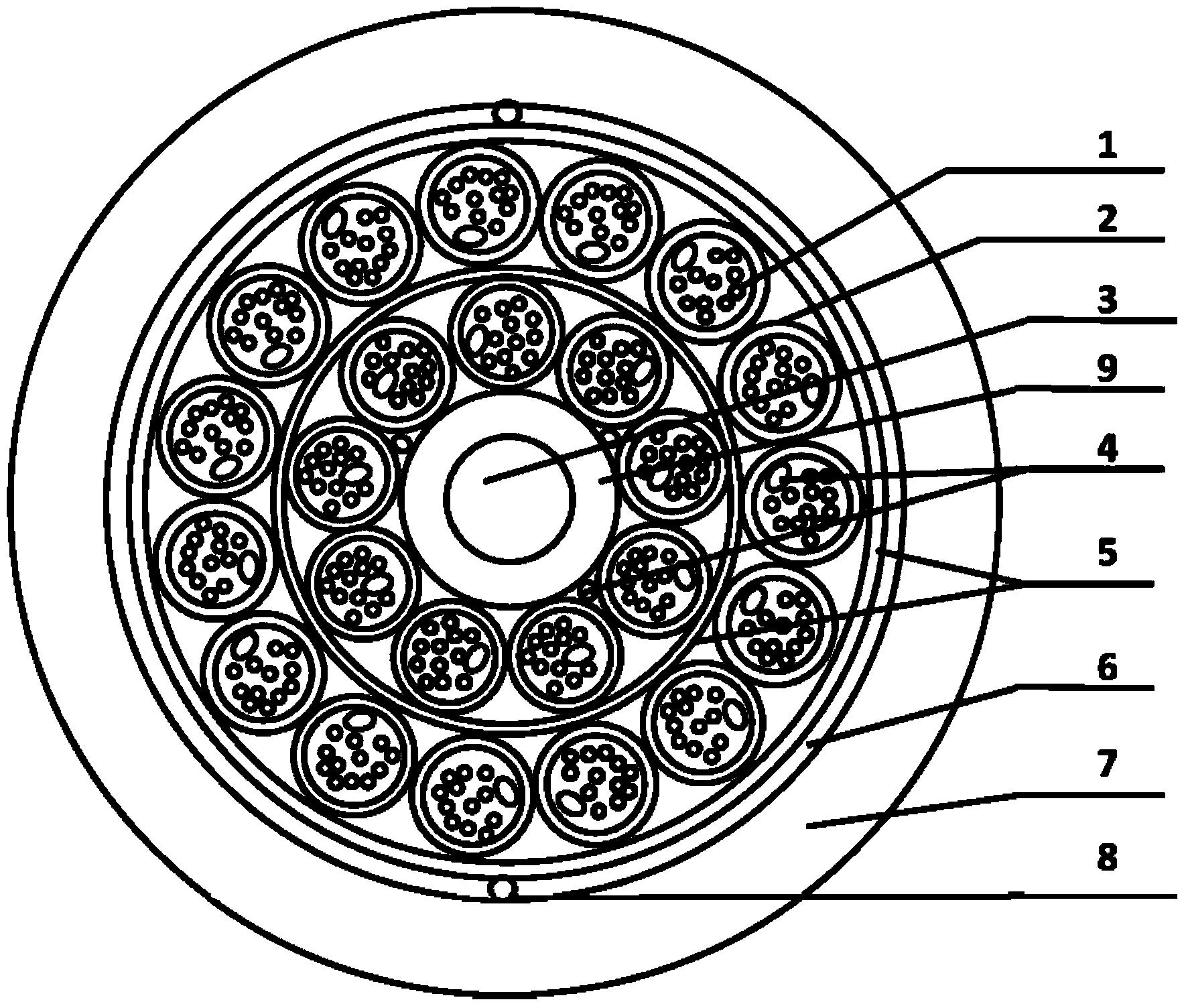

[0043] Embodiment 3: 1+9+15 structure

[0044] see image 3 As shown, the double-layer stranded fully dry optical cable in embodiment 3 includes a central strengthening component, a double-layer twisted cable core, a water blocking tape 5, a reinforcing yarn 6 and an outer sheath layer 7, and the central strengthening component includes a strengthening core 3 and The plastic cushion 9 and the reinforcing core 3 are made of phosphating steel wire, and the outer surface of the reinforcing core 3 is wrapped with a plastic cushion 9 made of polyethylene. The outer surface of the plastic cushion layer 9 of the central reinforcement component is spirally wrapped with three water-blocking yarns 4 with a linear density of 5000dtex. The loose tubes are stranded by SZ: 9 loose tubes 2 in the inner layer, 15 loose tubes 2 in the outer layer, and the loose tubes 2 are all dry loose tubes, made of modified polypropylene, each loose tube The sleeve 2 contains 12 optical fibers 1 and 1 wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com