Self-assembling peptide surfaces for cell patterning and interactions

a peptide surface and cell patterning technology, applied in the field of self-assembling peptide surfaces for cell patterning and interactions, can solve the problems of sams, can be difficult and/or expensive to manufacture, and achieve the effect of convenient manufacture and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

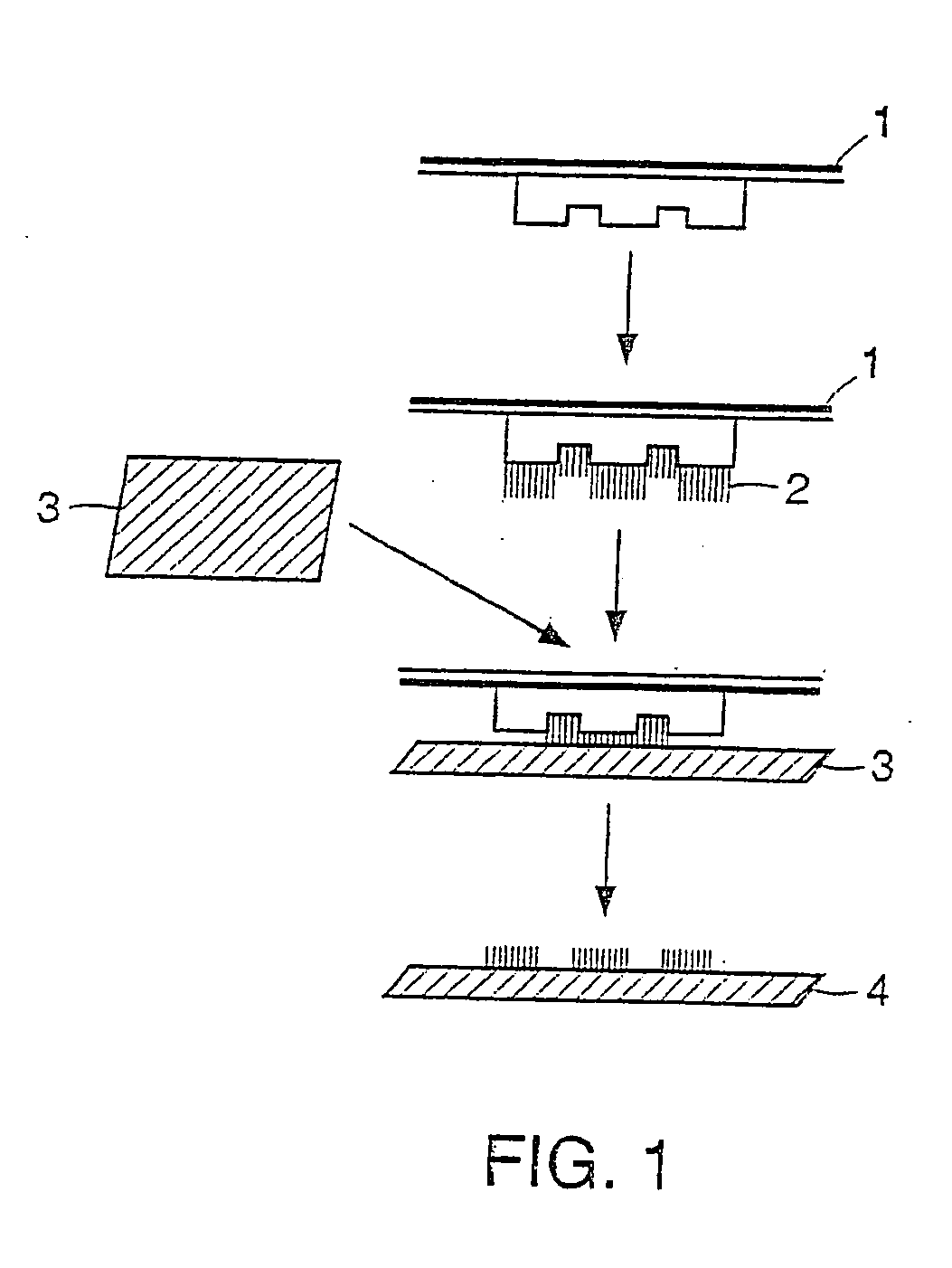

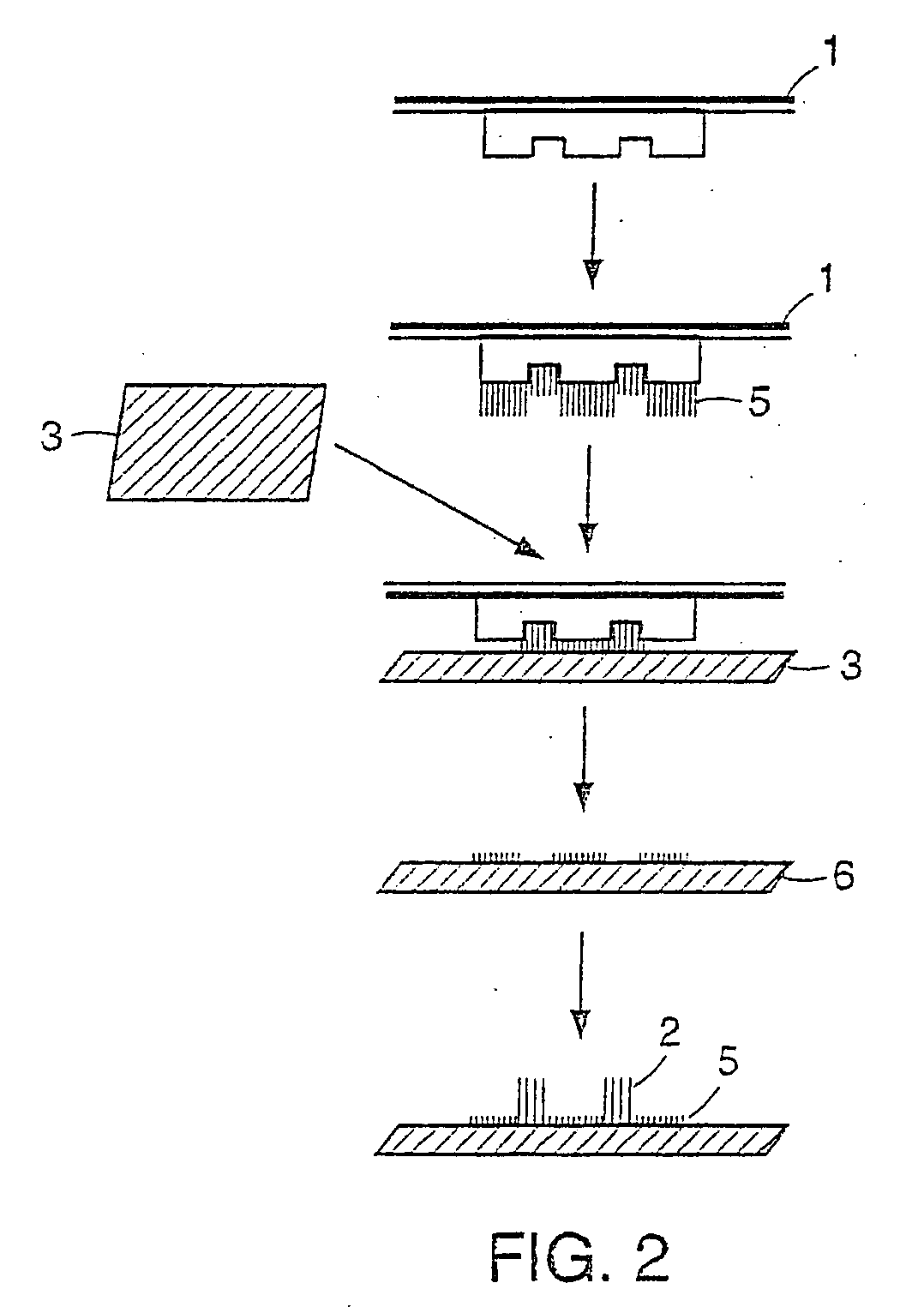

Preparation of Patterned SAMs Glass Chip

[0069] A 10:1 (w:w) mixture of Sylgard Silicone Elastomer 184 and Sylgard Curing Agent 184 (Dow Corning Corp., Midland, Mich.) was casted over a master, which was generated by photolithography, and pressure degassed. After sitting at room temperature for 1 hour, the PDMS was cured at 60° C. for 2 hours. The stamp was carefully peeled off the master after cooling to room temperature and rinsed with ethanol. The PDMS stamp was inked by a cotton swab which has been moistened with a 5 mM solution of (1-mercaptoundec-11-yl)hexa(ethylene glycol) (HO(CH2CH2O)6(CH2)11SH) in ethanol. The resulting stamp was placed on the gold substrate (125 ★ gold on a titanium-primed 24×50-2 microscope cover glass) and gentle hand pressure was applied to aid in complete contact between the stamp and the glass chip. After 1 minute, the stamp was peeled off the glass chip and the resulting substrate was immersed directly in a 2 mM solution of (RADC)3 AAAC (SEQ ID NO: 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com