Supply recycling system and valuable-metal recovering system

a recycling system and valuable metal technology, applied in the field of toner product recycling technology, can solve the problems of inability to semi-permanently continue recycling processing, no longer economical value of recycling by that means, and means that must be abandoned, so as to achieve low powdering ratio, reduce production costs, and high molding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Exemplary embodiments of the present invention will be explained in detail below with reference to the accompanying drawings.

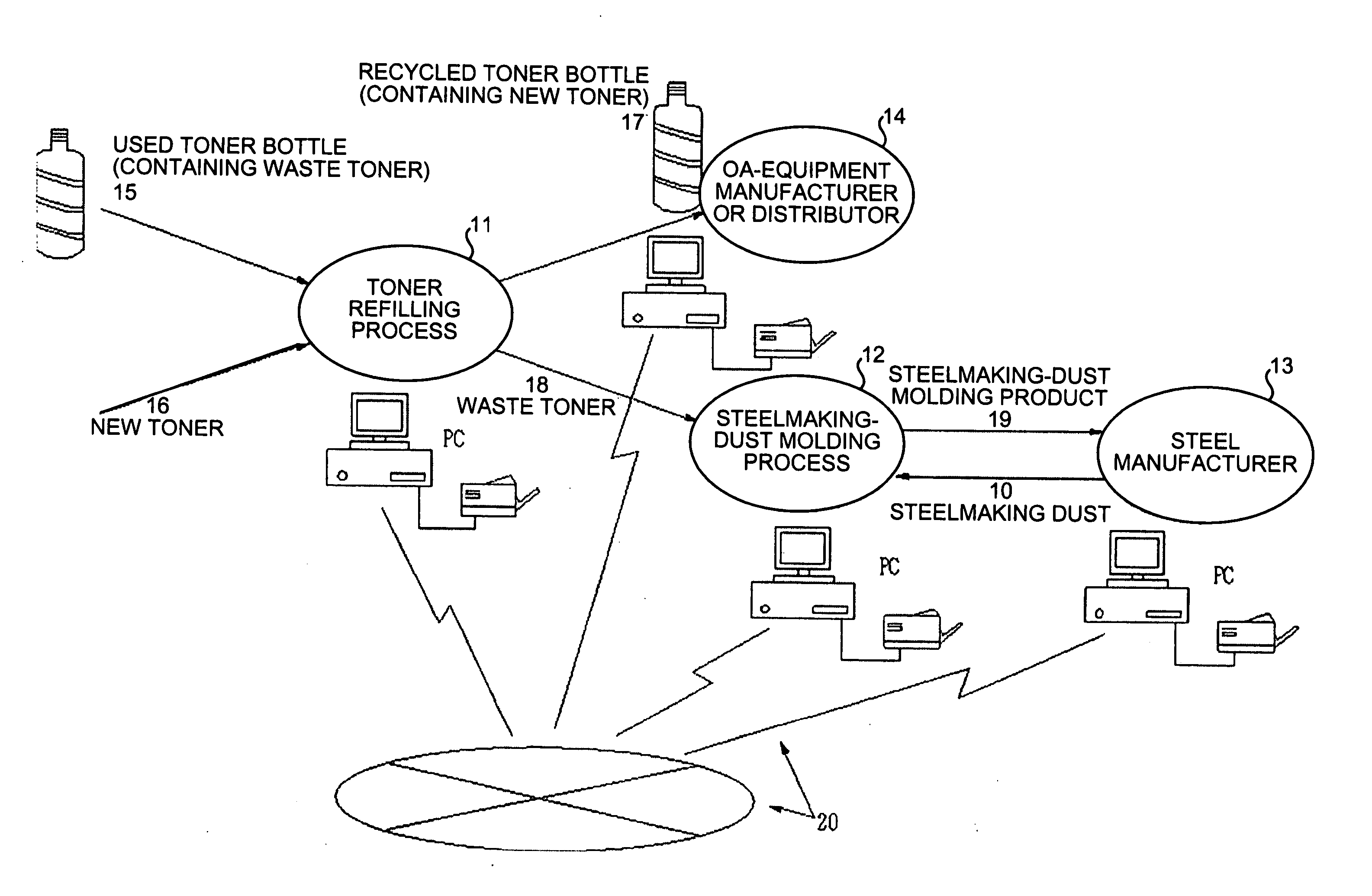

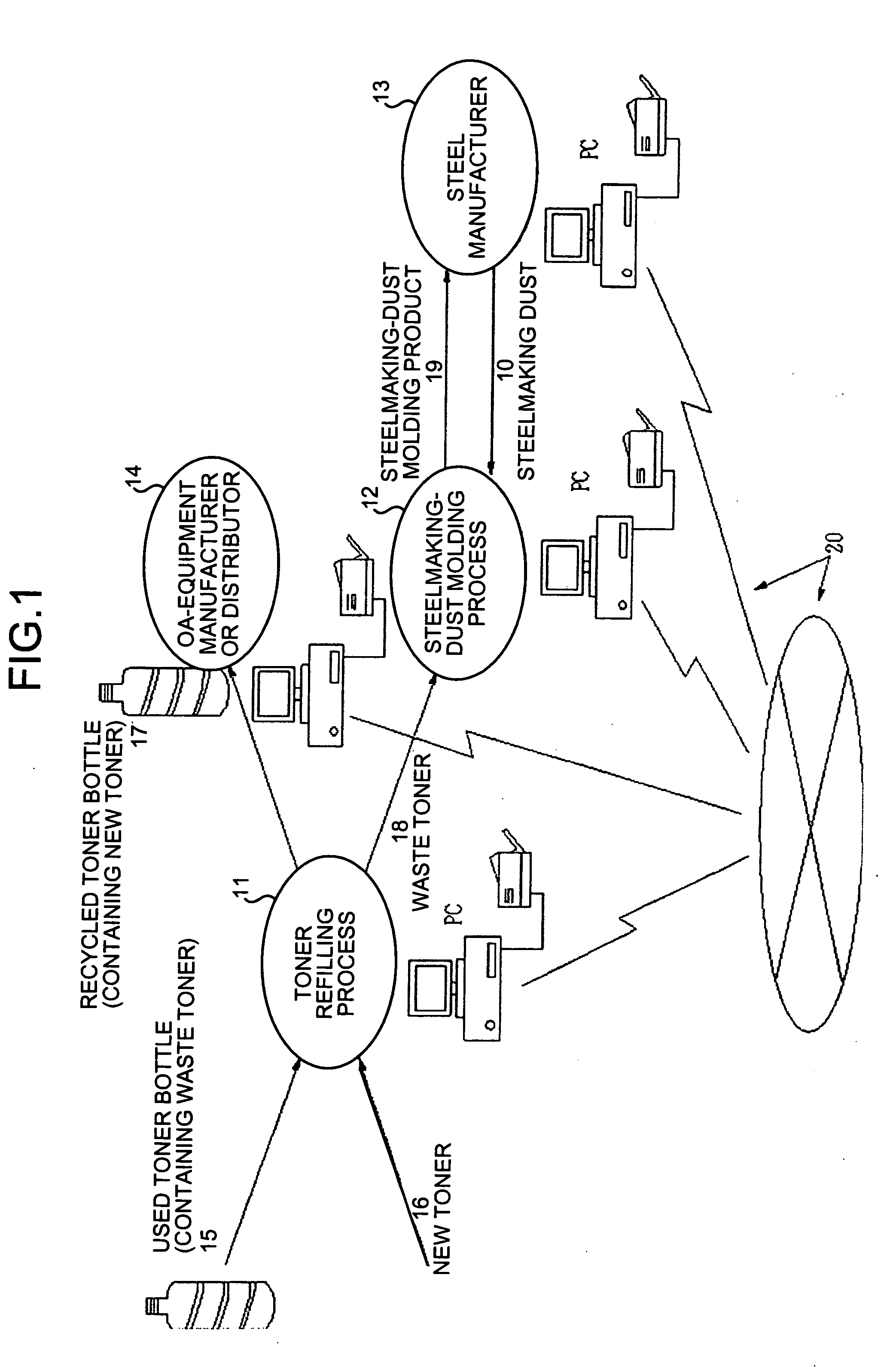

[0049]FIG. 1 is a schematic diagram of a supply recycling system according to an embodiment of the present invention. According to the present embodiment, a network 20 is used, which can be any of various types of networks including the Internet, an intranet, or the like. The PCs in FIG. 1 are terminal devices such as a personal computer used in respective processes and peripheral equipment thereof (e.g., a functional part such as a board having a communication function, or equipment such as a printer). Any known structure and any type thereof can be employed for the terminal device PC.

[0050] As shown in FIG. 1, a used toner bottle 15 is collected from the market in a toner refilling process 11. There are two types of forms in recovering the used toner bottle 15. A first form is that the toner bottle 15 is recovered per product main body as is in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| colors | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com