Roofing system and roofing tile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

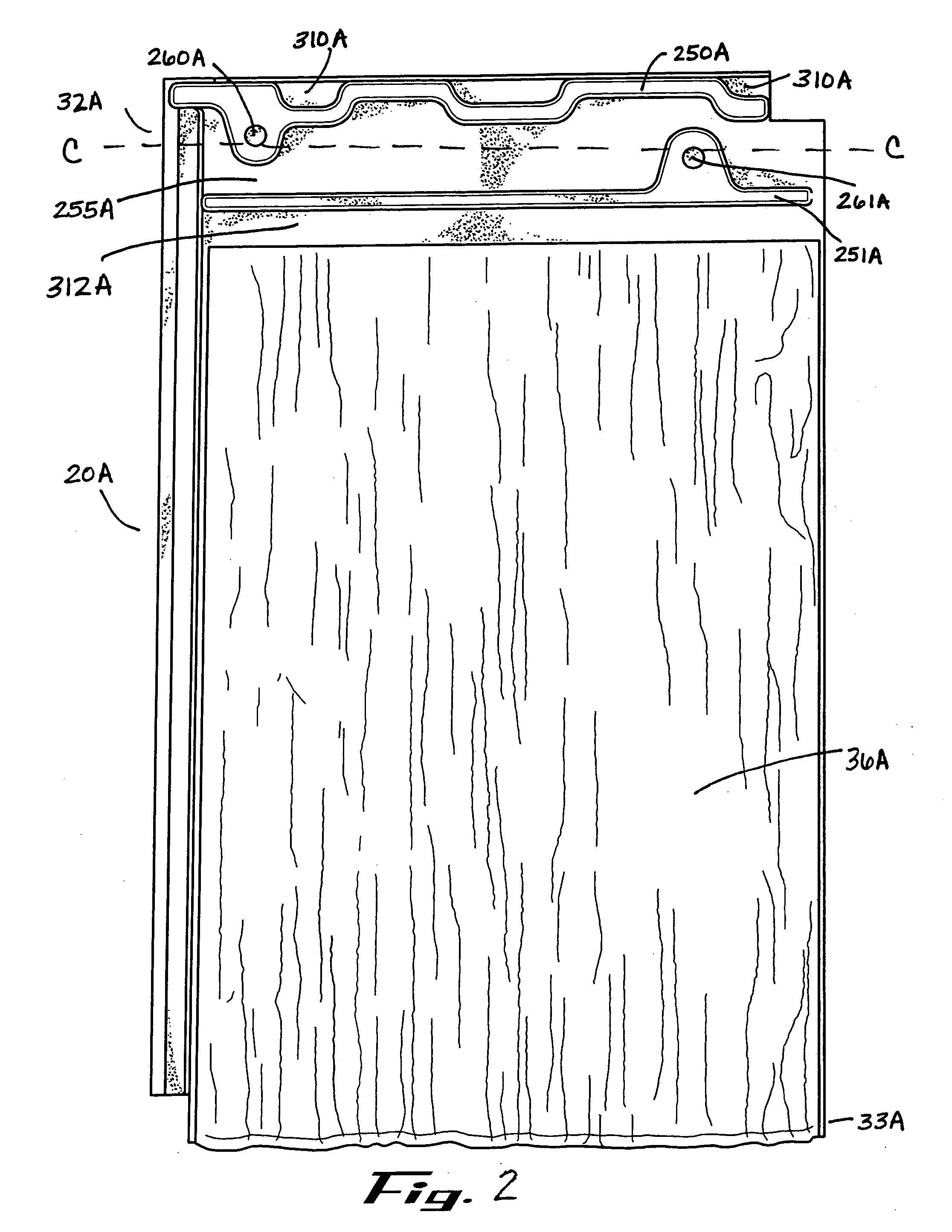

[0032] The present invention addresses the above needs and achieves other advantages by providing a roofing system that includes roofing tiles that have one of at least two profiles. In one embodiment, a portion of the tiles has an “A” profile, and a portion of the tiles has a “B” profile. When the tiles having an “A” profile are installed alternately or in a random fashion with tiles having a “B” profile, the tiles simulate the appearance of a wood shake roof, as shown in FIG. 21. The structures of each of the profiles according to one embodiment are described below in the section “Tile Structure,” and exemplary methods of manufacturing the tiles and installing the tiles are described below in the sections “Method of Manufacturing the Tiles” and “Method of Installing the Tiles,” respectively.

[0033] Tile Structure

[0034]FIGS. 1 through 8 illustrate an embodiment of a singe roofing tile having an “A” profile. The “A” profile tile 20A includes an upper face, a lower face, a “head” en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com