Wire feeder with non-linear speed control

a non-linear, wire feeder technology, applied in the direction of arc welding apparatus, welding tools, manufacturing tools, etc., can solve the problems of additional control switches, significant drawbacks, and confusion of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] While the present invention will be illustrated with reference to a particular front panel arrangement and a particular circuit diagram it should be understood at the outset that the wire feed speed control may be implemented with other components and lay-outs.

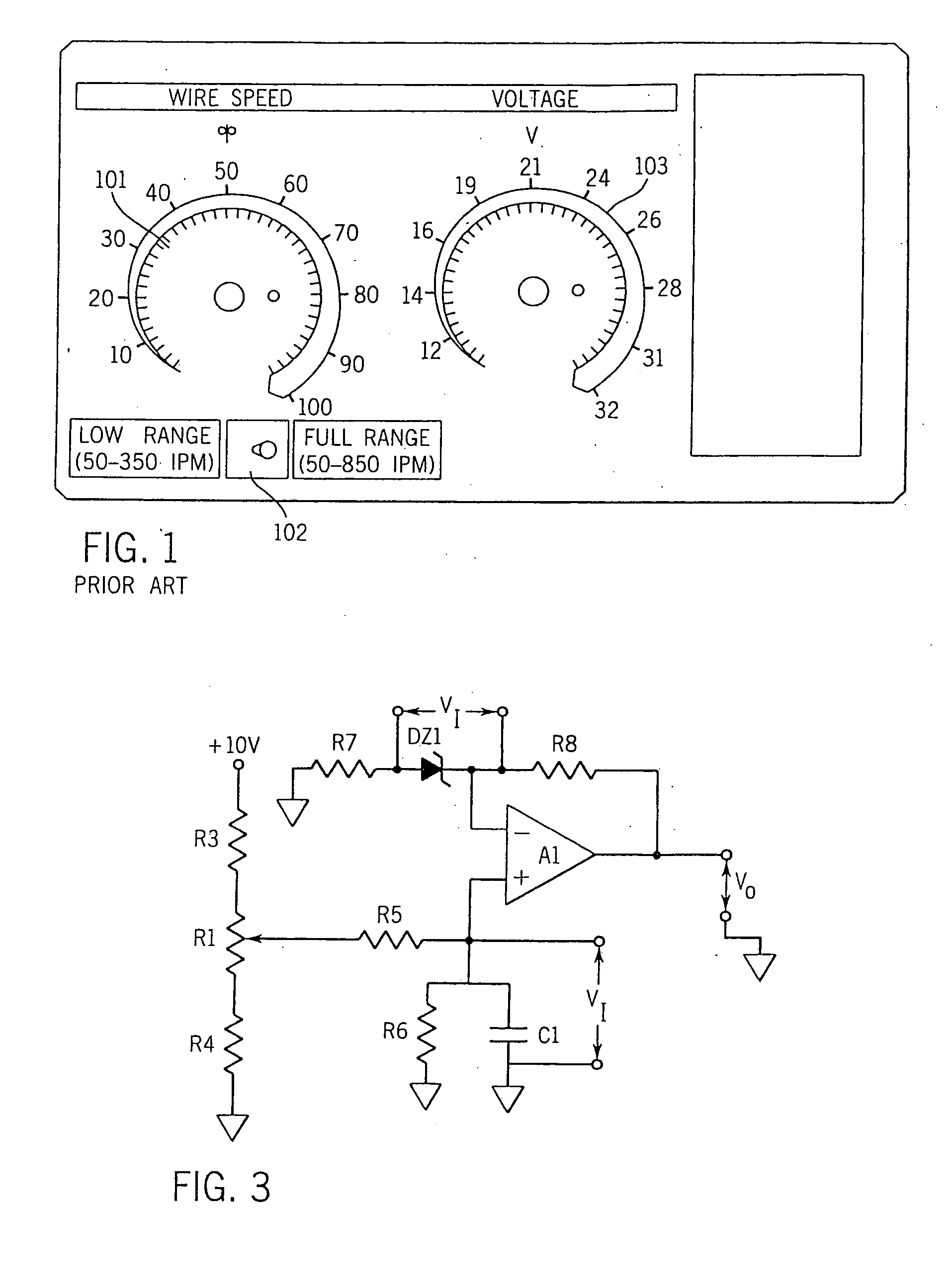

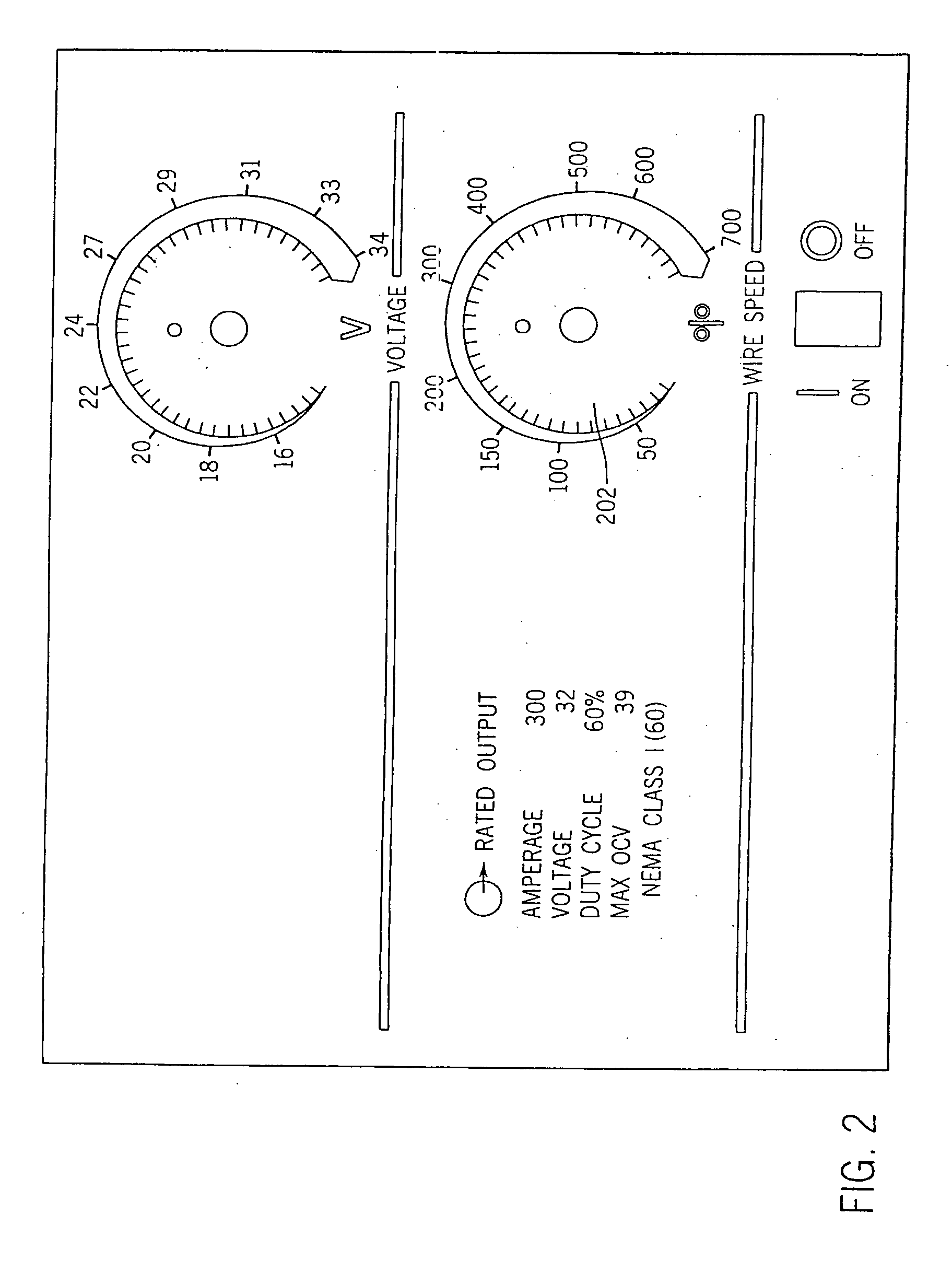

[0025] Generally, the present invention provides for a non-linear output of the wire feed speed control knob. The non-linear output voltage allows for greater sensitivity (per angular unit) at slower wire feed speeds, and lesser sensitivity (per angular unit) at faster wire feed speeds. This allows the wire feed speed to be displayed in inches per minute, and allows the user to effectively-select a wire feed speed over an entire range using a single potentiometer, without toggling a range switch.

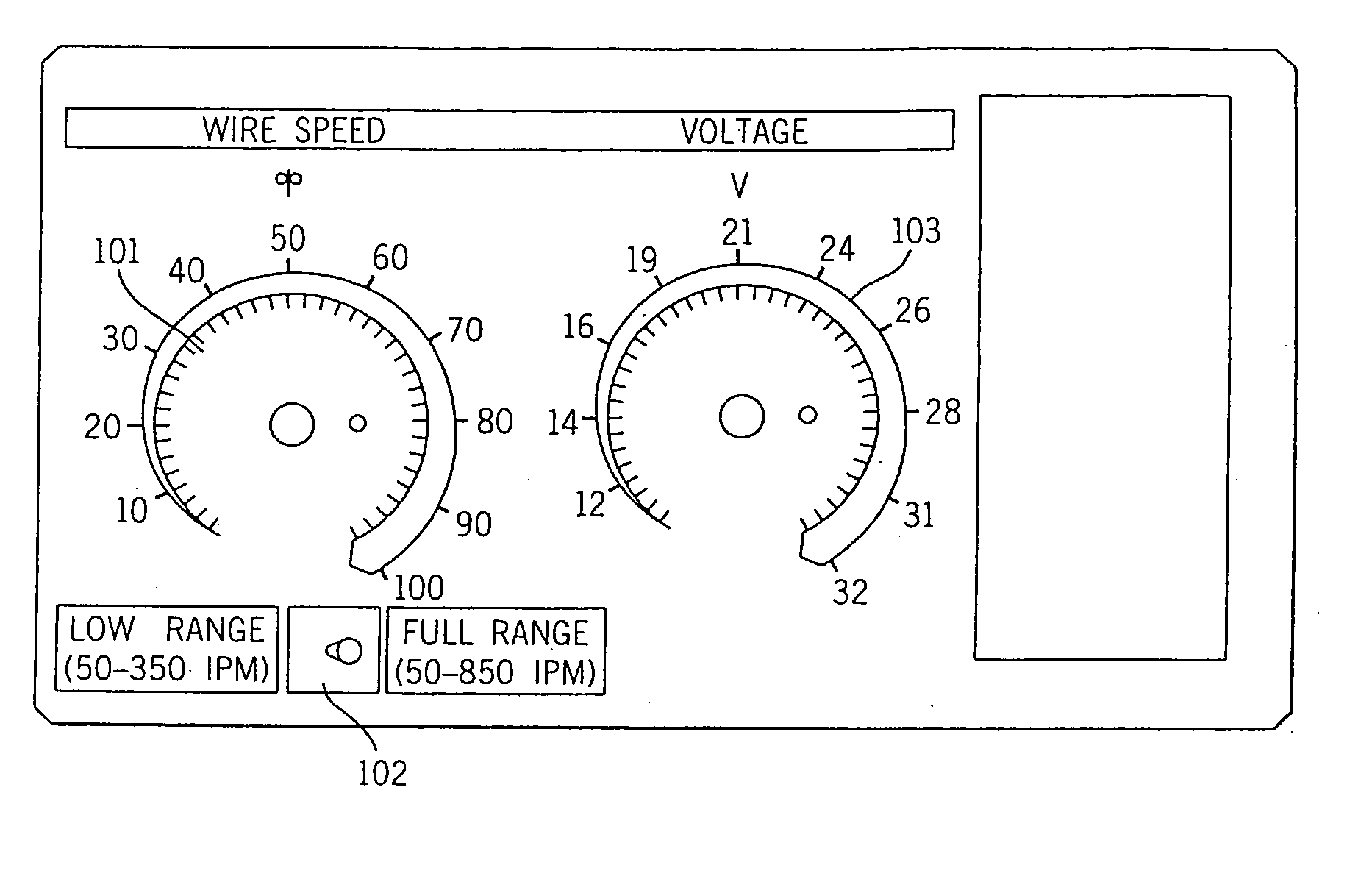

[0026]FIG. 2 shows a portion of a front panel of a wire feed speed controller (that corresponding to the portion of a prior art panel in FIG. 1) implementing the present invention. The wire feed speed is set using a knob 202 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com