Fabric membrane texture and manufacturing method thereof

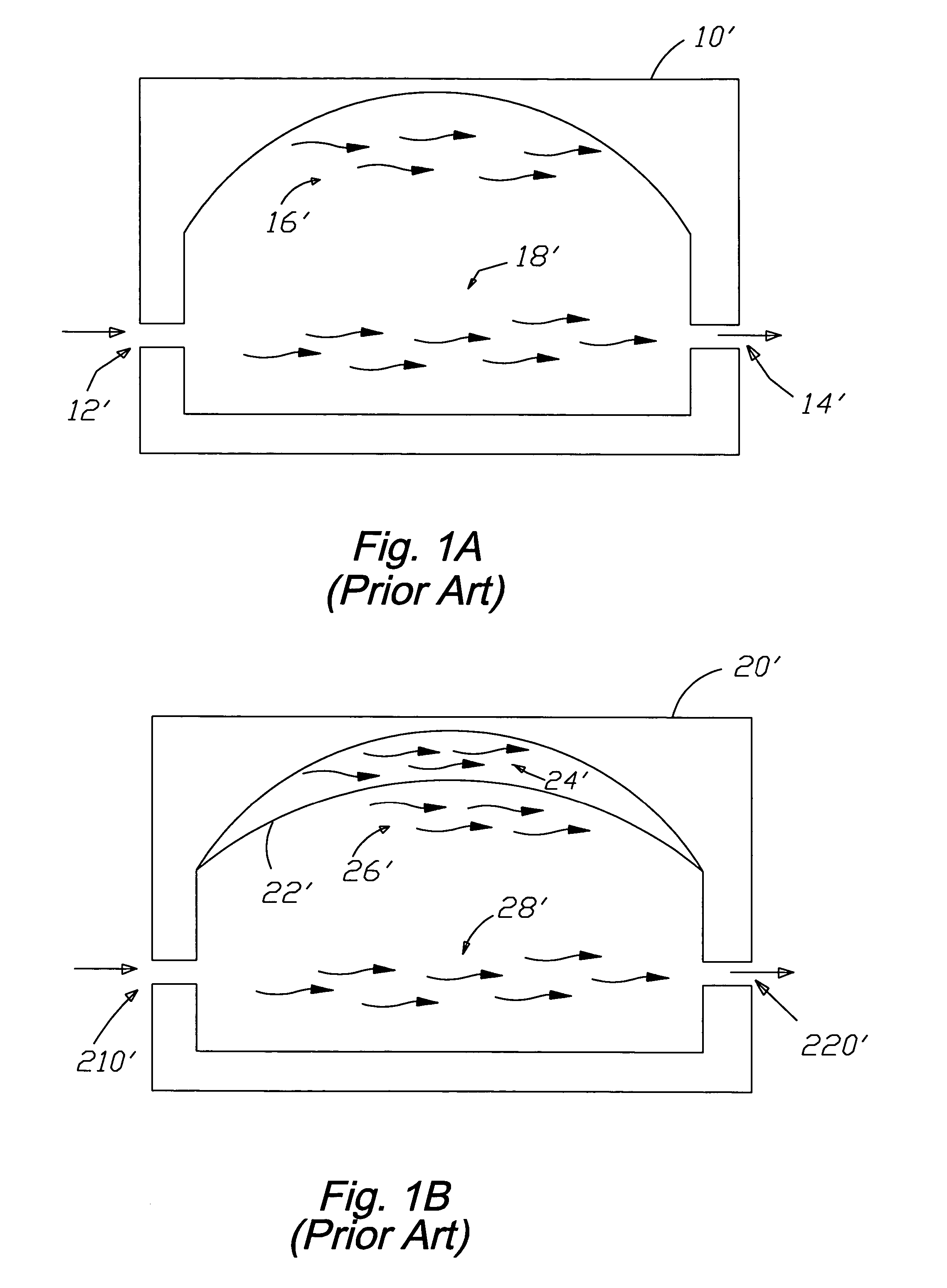

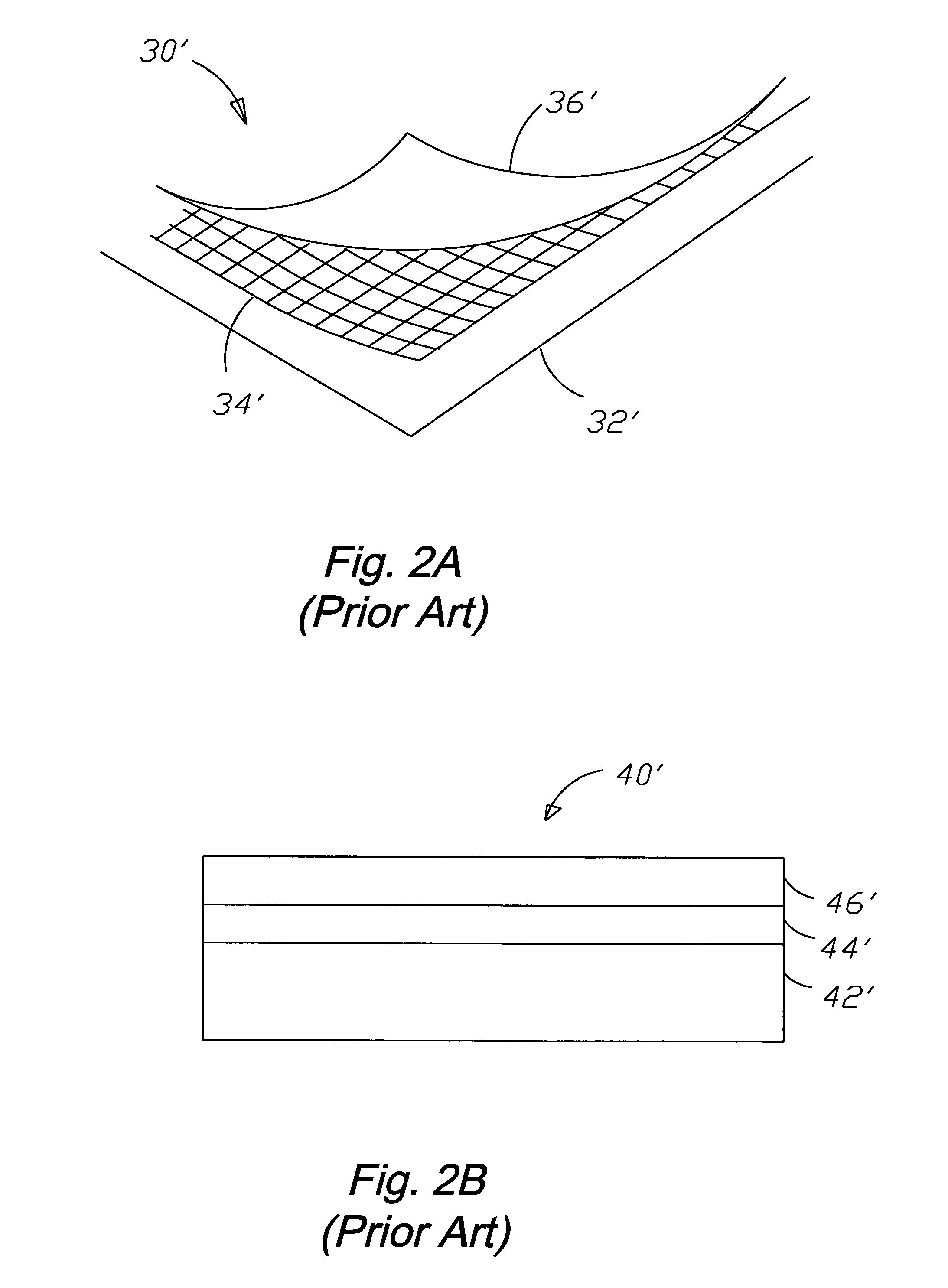

a technology of fabric membrane and manufacturing method, which is applied in the direction of knitting, ornamental textile articles, weaving, etc., can solve the problems of lack of impedance and insulation effect of light, heat and dynamics on the direction of thickness, and increase thickness, so as to improve the efficiency of high lightweight, shorten processing time, and stabilize the ability to obtain the best control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to clearly express and explore the feature characteristics and efficiency of the present invention for the committee of patent, the preferred embodiment and detailed description is as below.

[0023] The method of low-pressure fixation can evade the high temperature and high pressure resulting from the conventional roll adhesion used in the known art for fabric membranes and eliminate the crush damage to the middle connecting fibers which causes the serious impact of the development of size and characteristics of spacer.

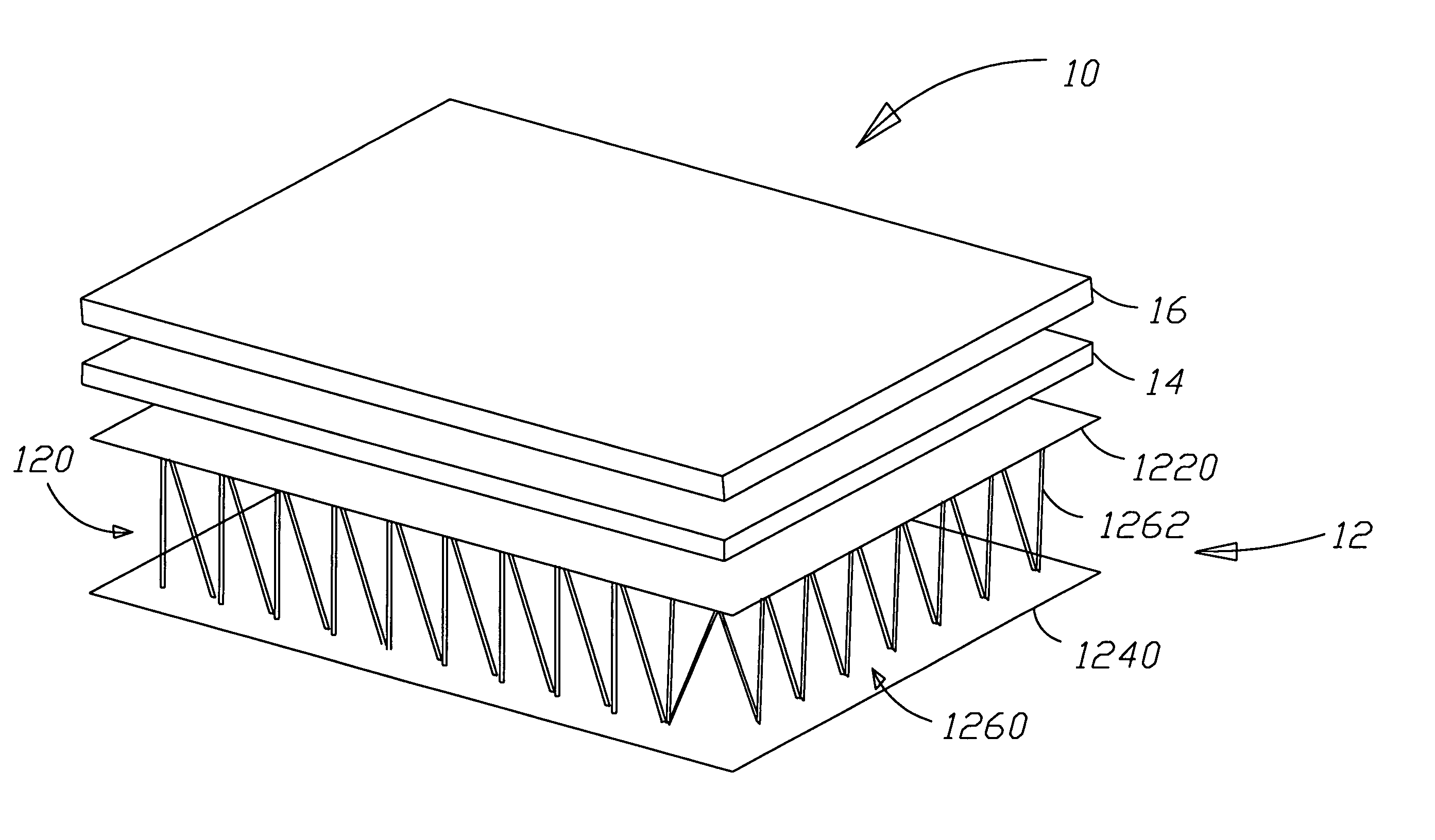

[0024] Refer to FIG. 3 is manufacturing flow chart of space fabric membrane for the preferred embodiment of the present invention that illustrates a manufacturing method of a space fabric membrane texture comprising the steps of: [0025] Step S10: adding an adhesive powder to at least one surface of a 3D fabric and preheating; [0026] Step S12: adhering at least a polymer membrane onto at least a surface of the 3D fabric using a low-pressure fixation pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal reflectance | aaaaa | aaaaa |

| thermal reflectance | aaaaa | aaaaa |

| specific distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com