Method and system for cooling the clutch system of a transmission

a transmission and clutch technology, applied in the direction of couplings, manufacturing tools, gearing, etc., can solve the problems of high energy consumption, limited temperature resistance of the clutch, and high energy consumption of the components of the clutch, so as to achieve the effect of acoustic advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

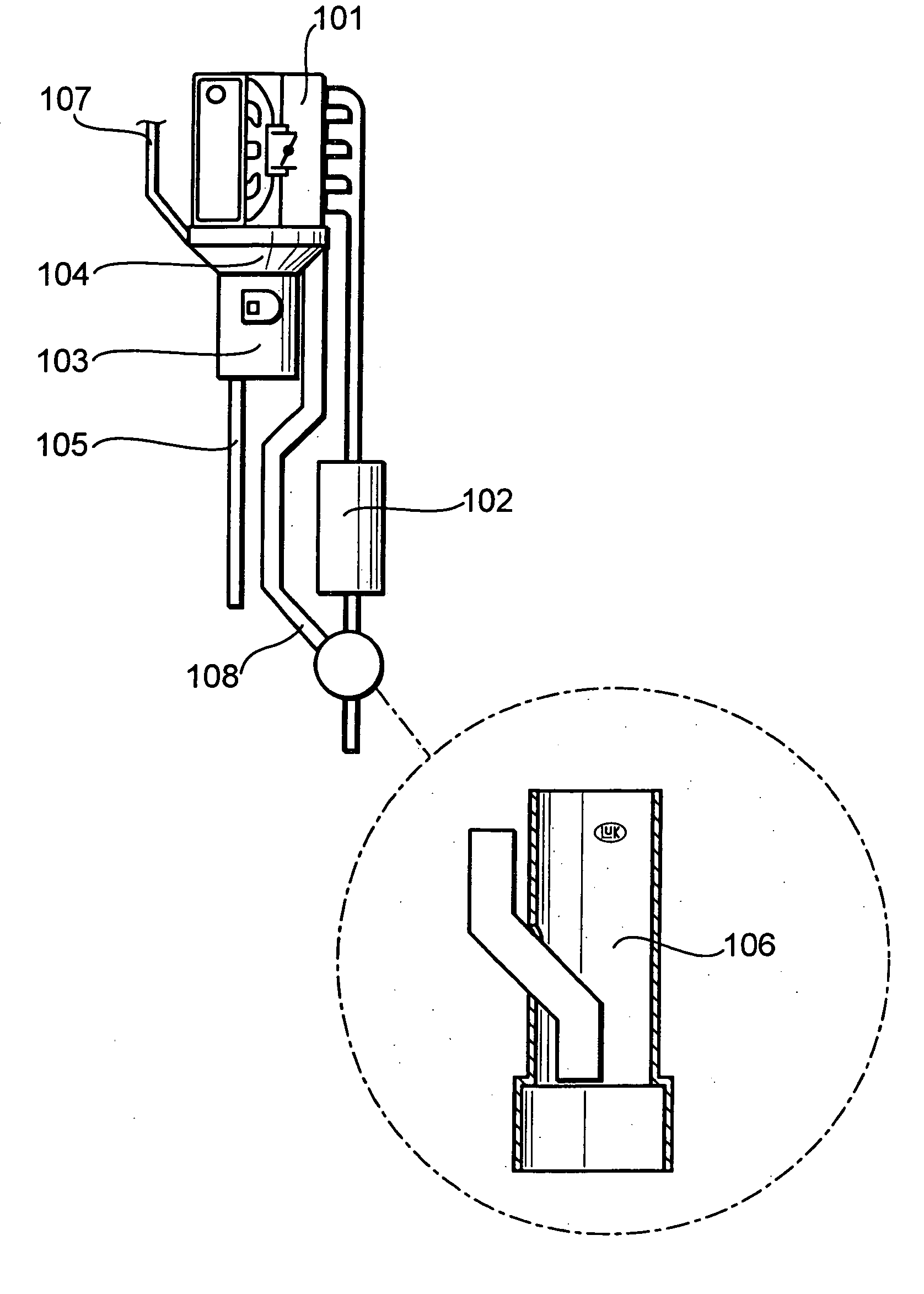

[0031] There is shown in FIG. 1 one possible embodiment of a system in accordance with the invention to cool a clutch, whereby an engine 101 with a connected exhaust gas system 102, and a transmission 103 with a clutch bell 104, as well as a drive shaft 105, are shown in schematically. In addition, there is shown in FIG. 1 an exemplary existing air inlet 107, for example for the windshield for ventilating the motor vehicle interior, which is utilized additionally for the cooling airflow in accordance with the invention. Other air inlets can also be provided for the cooling airflow.

[0032] The cooling airflow can be withdrawn from the clutch bell 104 by means of at least one air outlet 108 through a jet pump 106. The jet pump 106 is located in the exhaust system 102, and which is shown larger in the FIG. 1 enlargement portion.

[0033] The system in accordance with the invention, by interconnection with the existing air inlet system and exhaust gas system provided in the motor vehicle,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

| frictional torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com