Apparatus and method for reducing electrical noise in a thermally controlled chuck

a technology of electrical noise reduction and thermal control, which is applied in the field of apparatus and methods for reducing electrical noise in thermal control chucks, can solve the problems of degrading the performance accuracy of testing, one source of electrical noise, and continuing to decrease the cost of individual integrated circuit chip dies in comparison to ic package costs, so as to achieve the effect of reducing the electrical noise introduced by the fluid and carrying out more accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

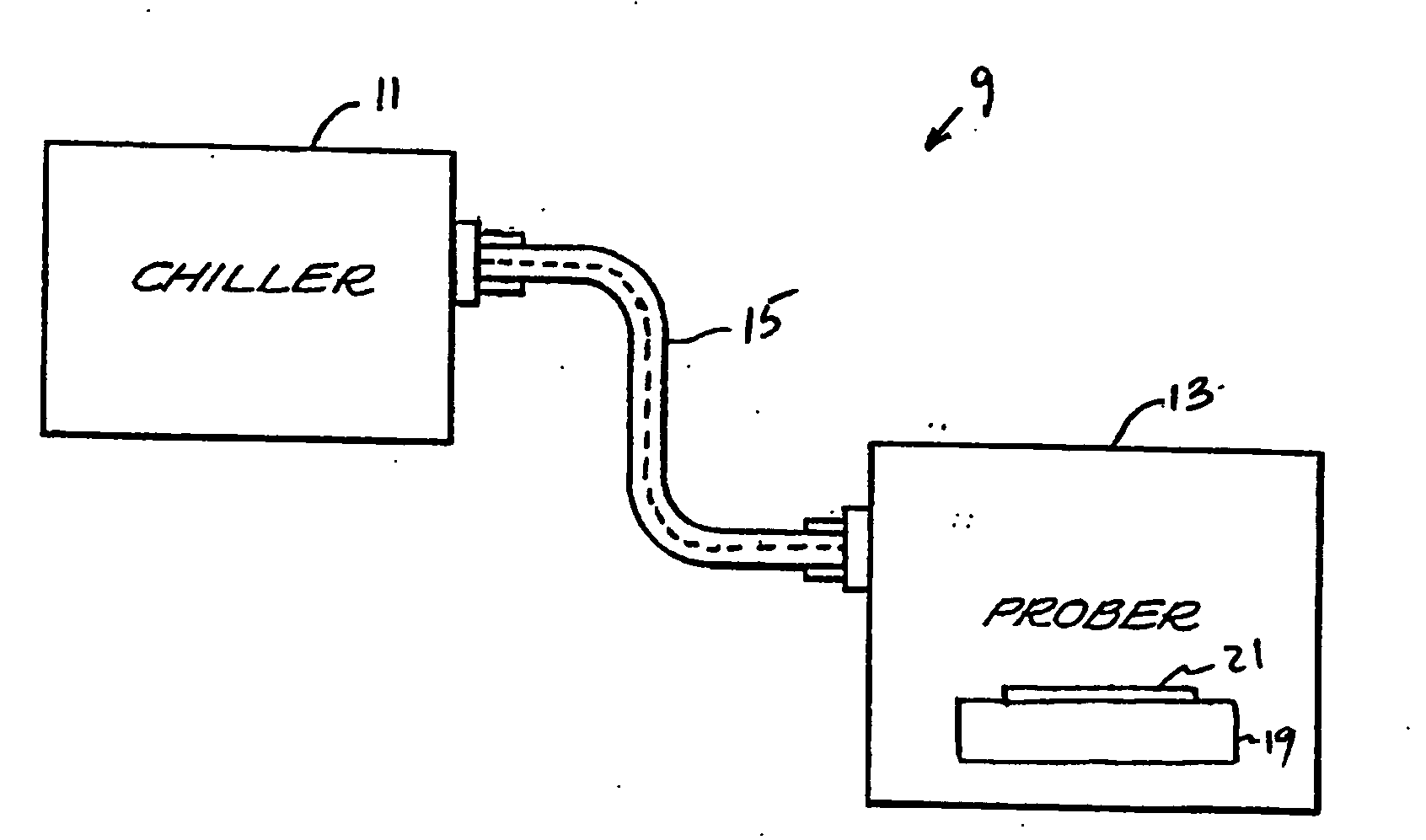

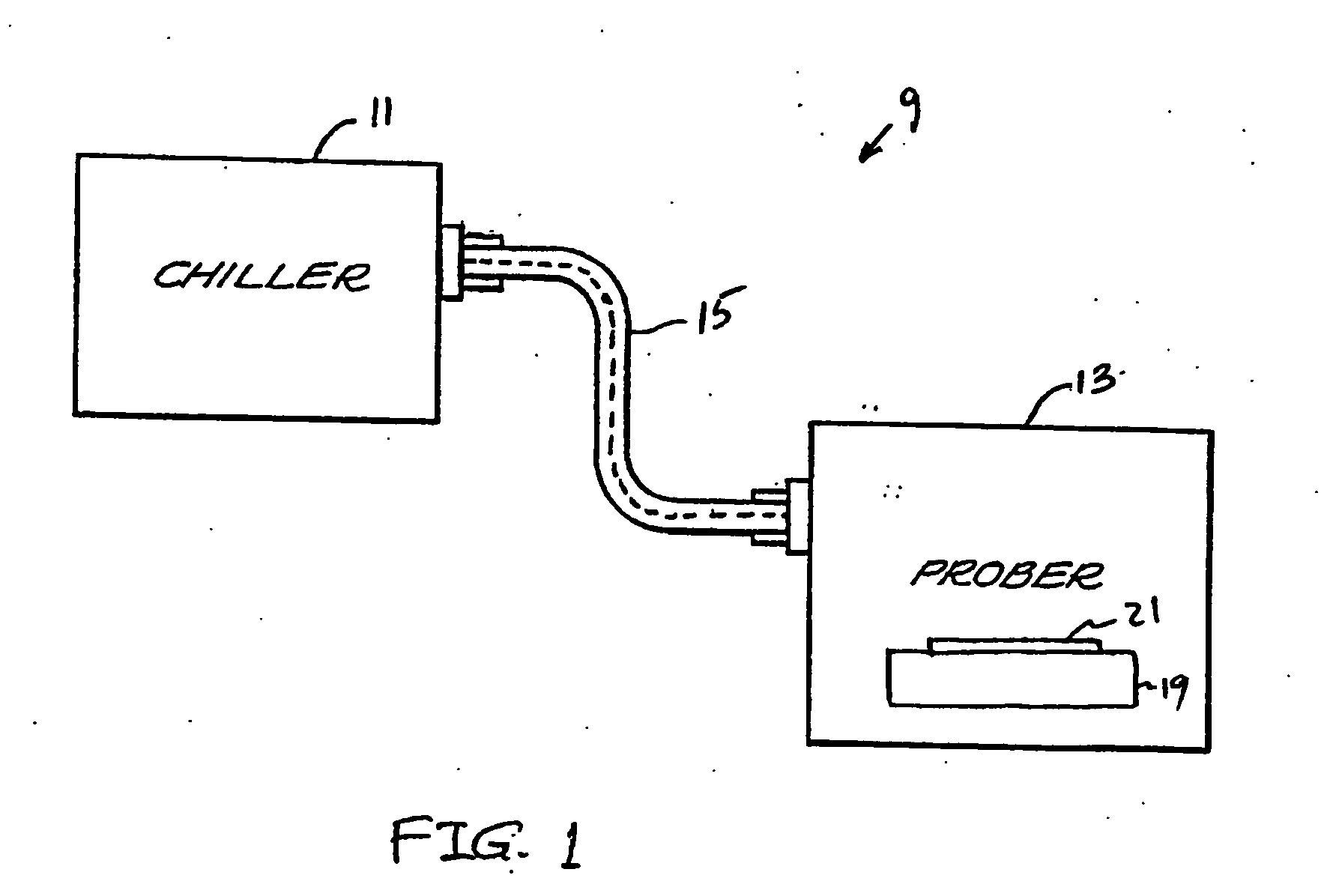

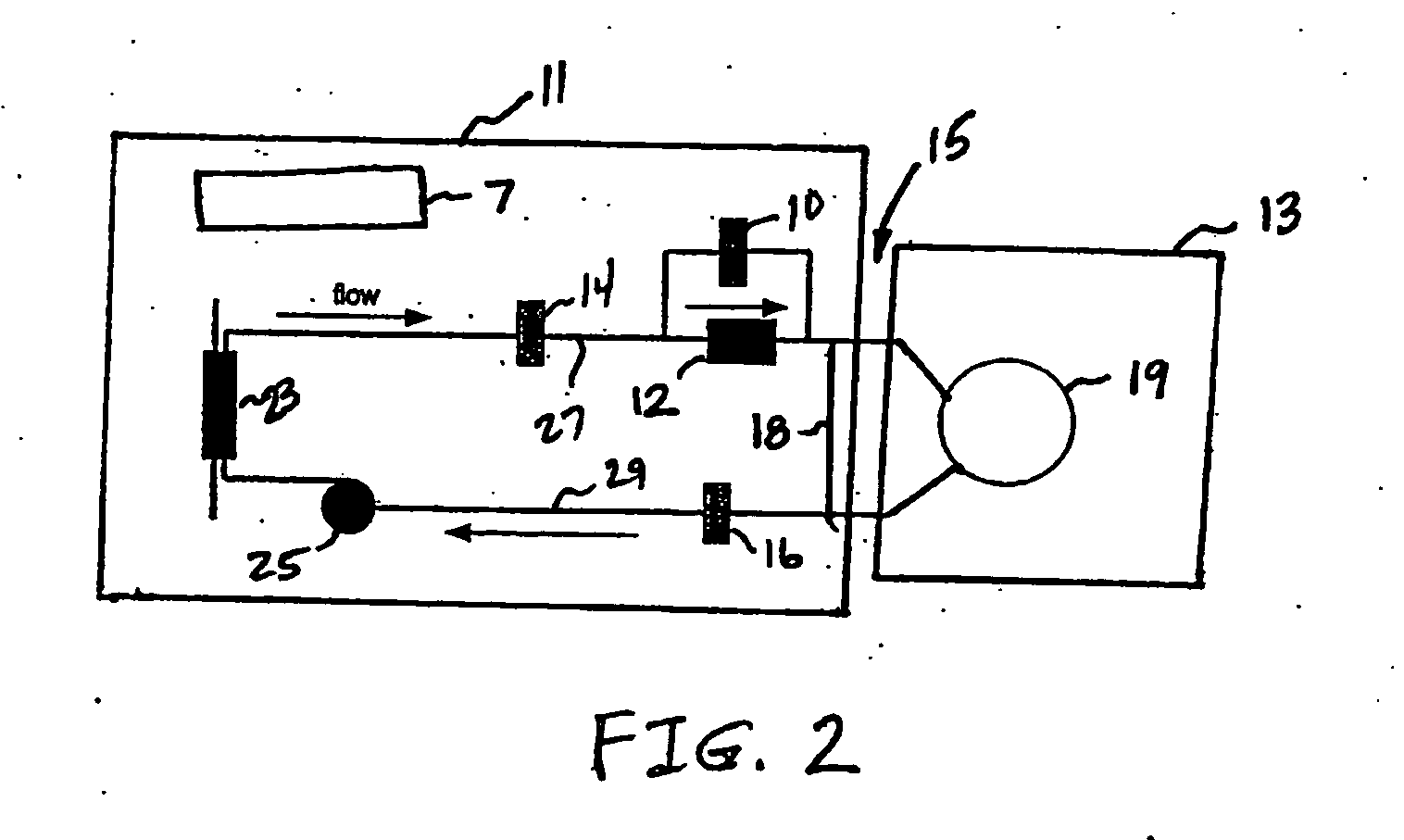

[0020]FIG. 1 contains a top-level schematic block diagram of a temperature control system and workpiece chuck connected to control temperature of a workpiece such as a semiconductor wafer mounted on the workpiece chuck. The system 9 includes a temperature control system such as a chiller 11, which controls the temperature of a temperature control fluid. The chiller 11 can be of the type manufactured and sold by Temptronic Corporation of Sharon, Mass., the assignee of the present application. Specifically, the chiller can be a Model Number TP03500A Atlas Chiller, or similar system, which is modified to include features of the invention used to reduce electrical noise as described herein.

[0021] The temperature control fluid is routed to and from a test system, such as, for example, a wafer prober 13, along a hose or pipe 15. The hose or pipe 15 can be of the type described in U.S. Pat. No. 6,070,413, assigned to Temptronic Corporation of Sharon, Mass., and incorporated herein in its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com