Heat transfer catheters and methods of making and using same

a technology of heat transfer catheter and catheter body, which is applied in the field of heat transfer catheter equipment, can solve the problems of simple approach, clear contrary to the intent, and treatment fluid certainly could not contain toxic substances which would poison or harm the body, and achieve the effect of convenient collapsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

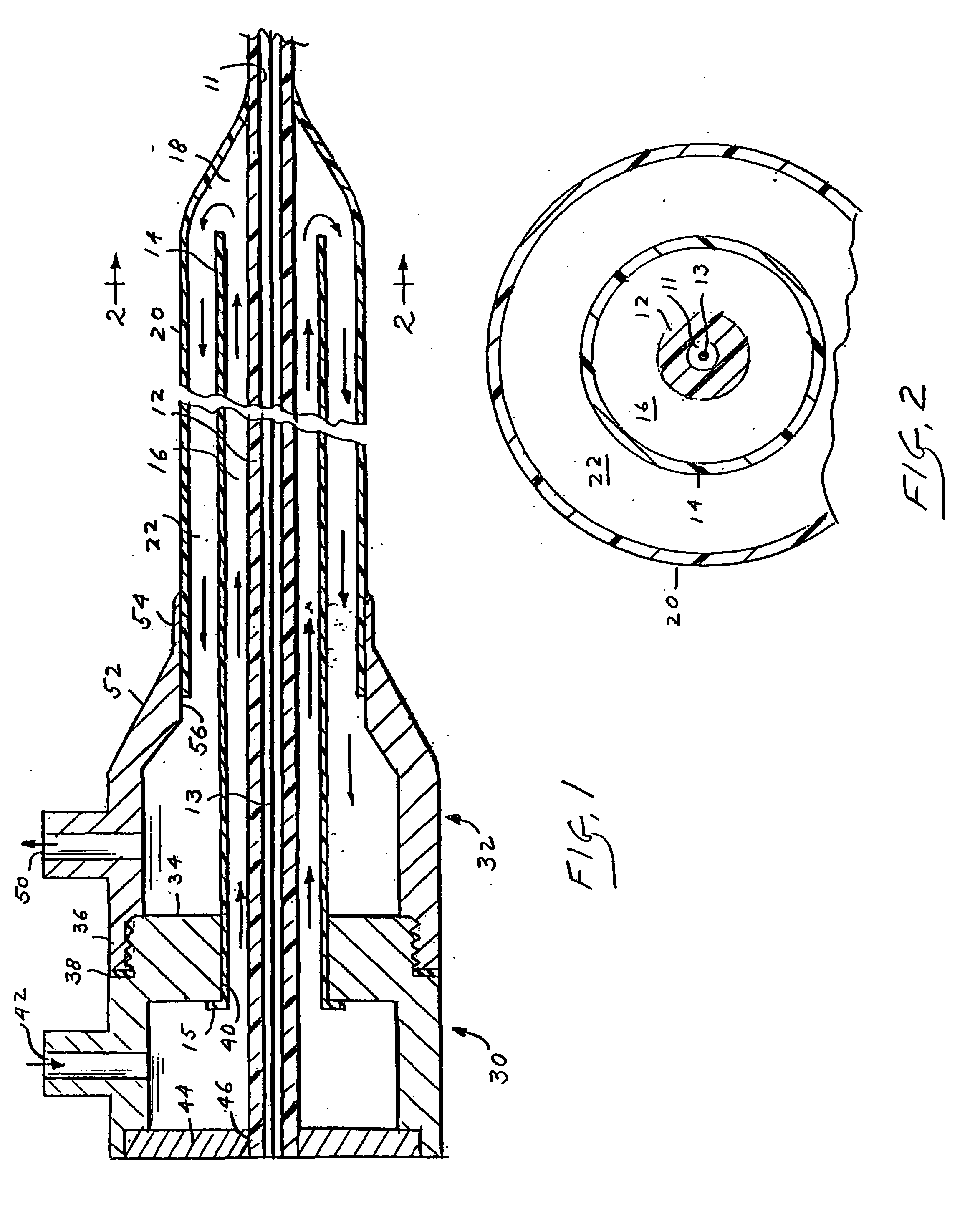

[0042] In each of the drawings, as described below, it should be understood that the wall thicknesses of the catheter and balloon lumens have been greatly exaggerated relative to other elements and to other dimensions for purposes of illustration.

[0043]FIG. 1 shows a schematic longitudinal sectional view of a heat transfer catheter apparatus 10 according to the present invention comprising a substantially concentric, coaxial configuration of multiple lumens or channels. The concentric, coaxial arrangement of the multiple lumens can be better understood by reference to FIG. 2, a cross-sectional view taken along the line 2-2 of FIG. 1. Returning to FIG. 1, a first, inner catheter tube 12 defines a central conduit 11 receiving a guide wire 13. Catheter tube 12 may be of conventional, thick-walled construction or, alternatively, comprise very thin sidewalls. For purposes of this invention, the terms “very thin walls” or “very thin-walled” refer to elongated sleeves or catheters having ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com