Electronic transformer/inductor devices and methods for making same

a technology of electric transformers and transformers, applied in the field of inductive components, can solve the problems of windings not being insulated by electric wires, and achieve the effects of improving magnetic performance, simplifying electrical connections, and superior heat removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

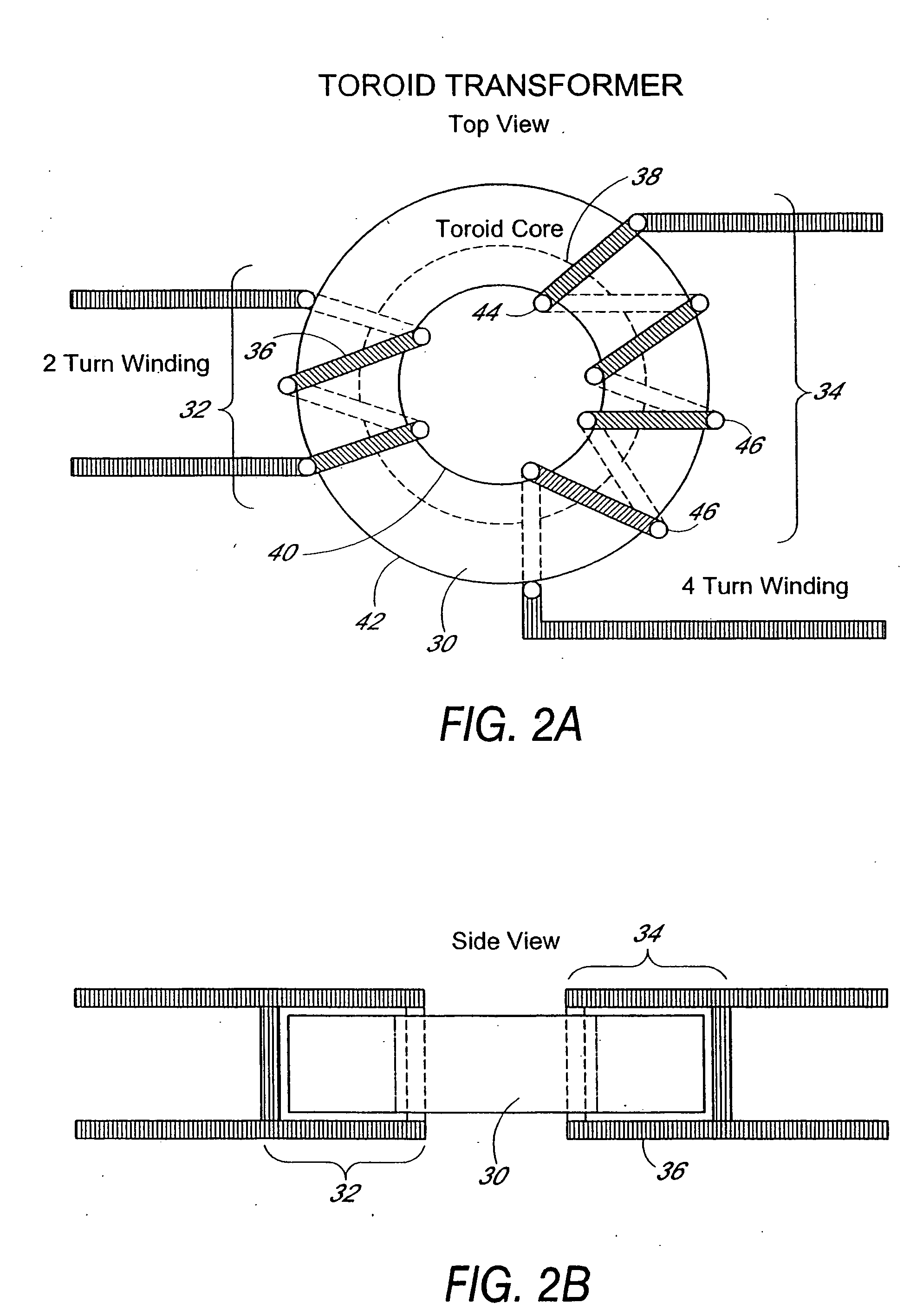

[0035]FIG. 2 illustrates a typical prior art transformer with a toroidal core 30. For simplicity this transformer has two windings of insulated wire: a two-turn winding 32 and a four-turn 34 winding. Each turn 36 encircles the material of the core 30 such that when electrical current is passed through one winding an encircling magnetic flux path 38 flows within the core 30. FIG. 2A illustrates the windings 32, 34 passing through the center of the core 30, and around the outside of the core 30.

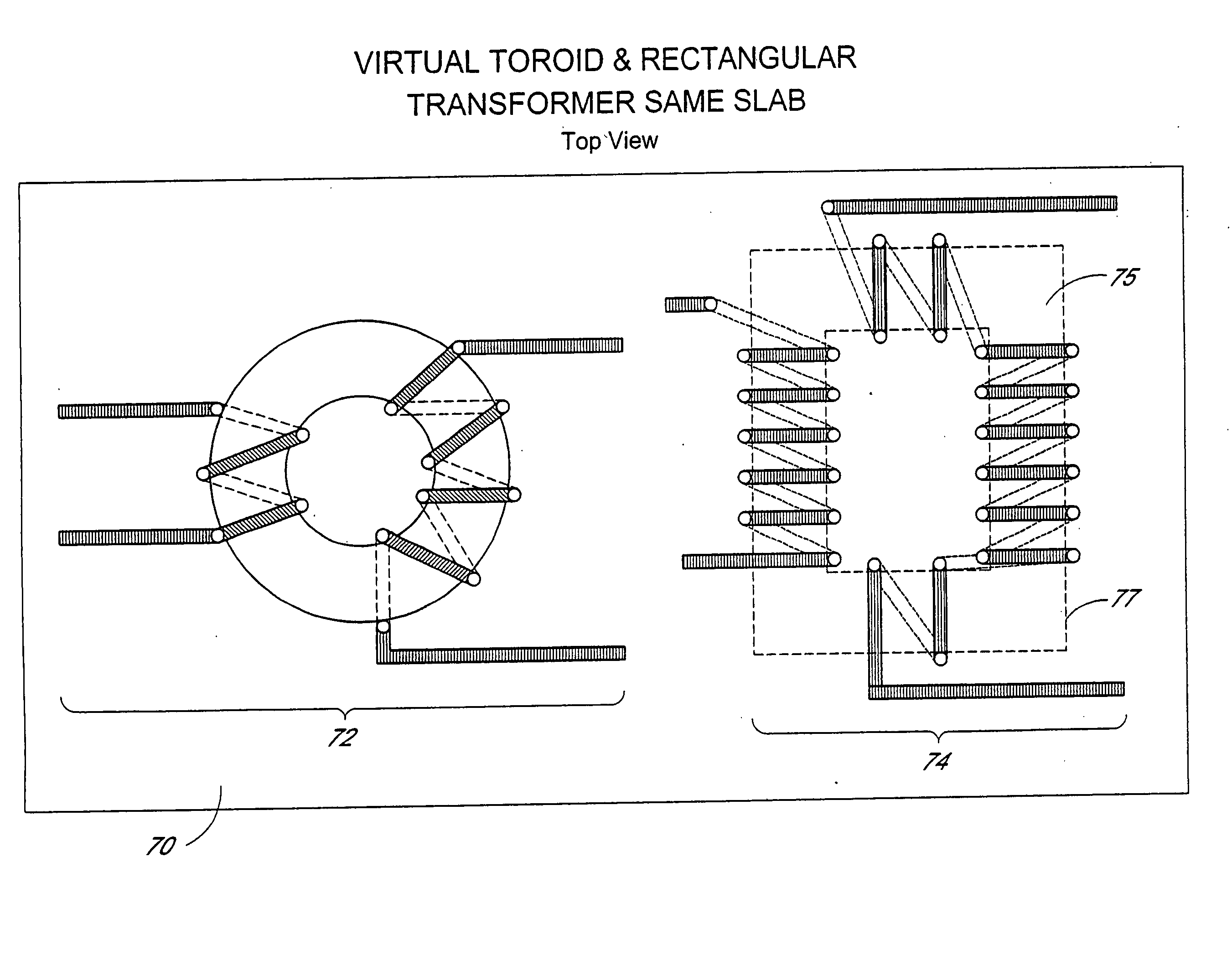

[0036] Preferred embodiments of the present invention have a very different core and winding arrangement. In one of these preferred embodiments shown generally in FIG. 3, slab 50 of ferromagnetic material has a top surface 52 and bottom surface 54, and, shown in cross-sections, two outer holes (vias) 56 and one inner hole (via) 64 within the slab 50. As described below, for miniature inductors and transformers, the slab 50 is advantageously a thin layer of ferrite having a relatively high resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com