Atomic layer deposition reactor

a technology of atomic layer and reactor, which is applied in the direction of chemical vapor deposition coating, metal material coating process, coating, etc., can solve the problems of contaminating the film, affecting the film quality, and exhibiting such ideal or near ideal behavior of precursors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

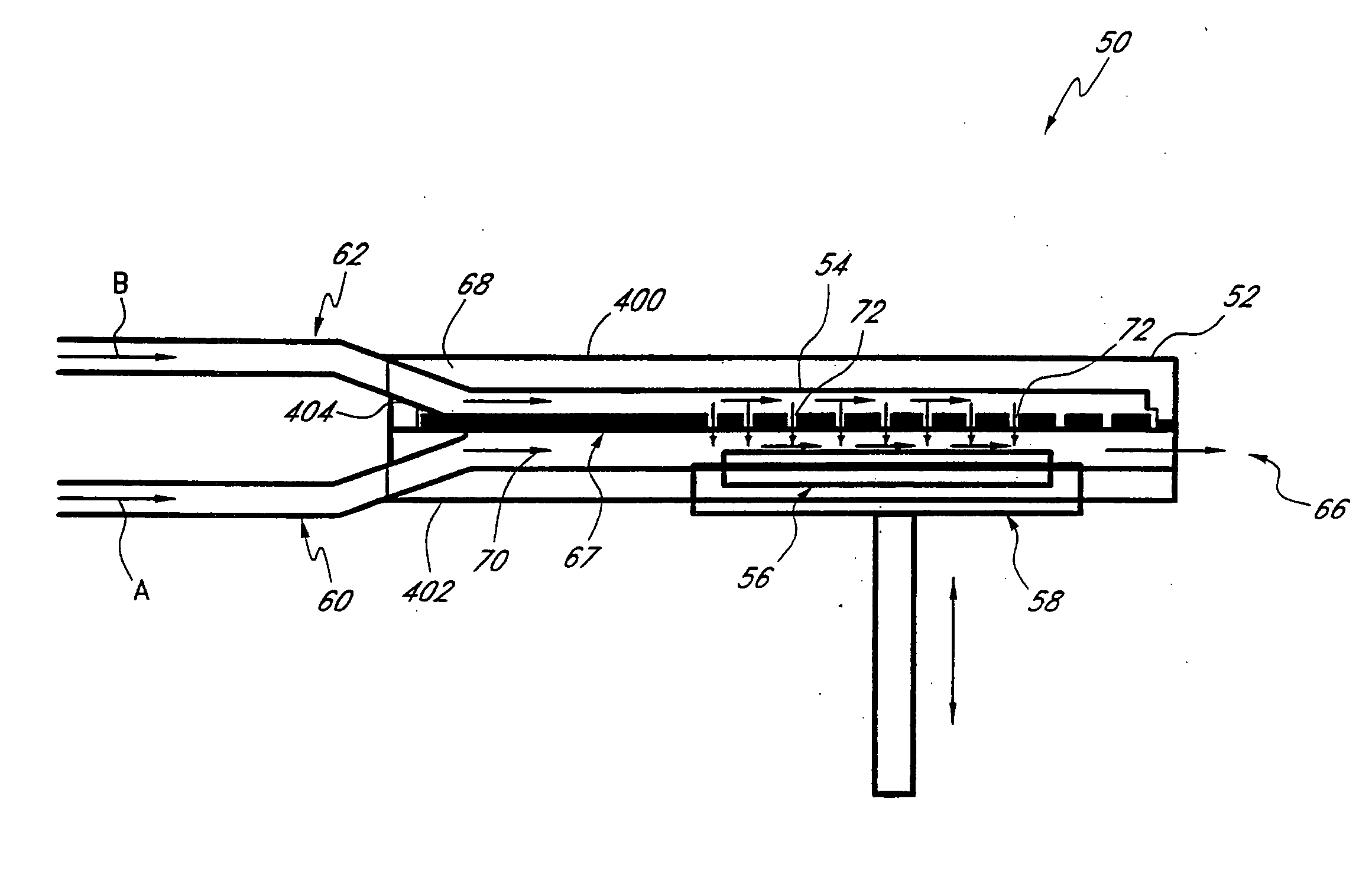

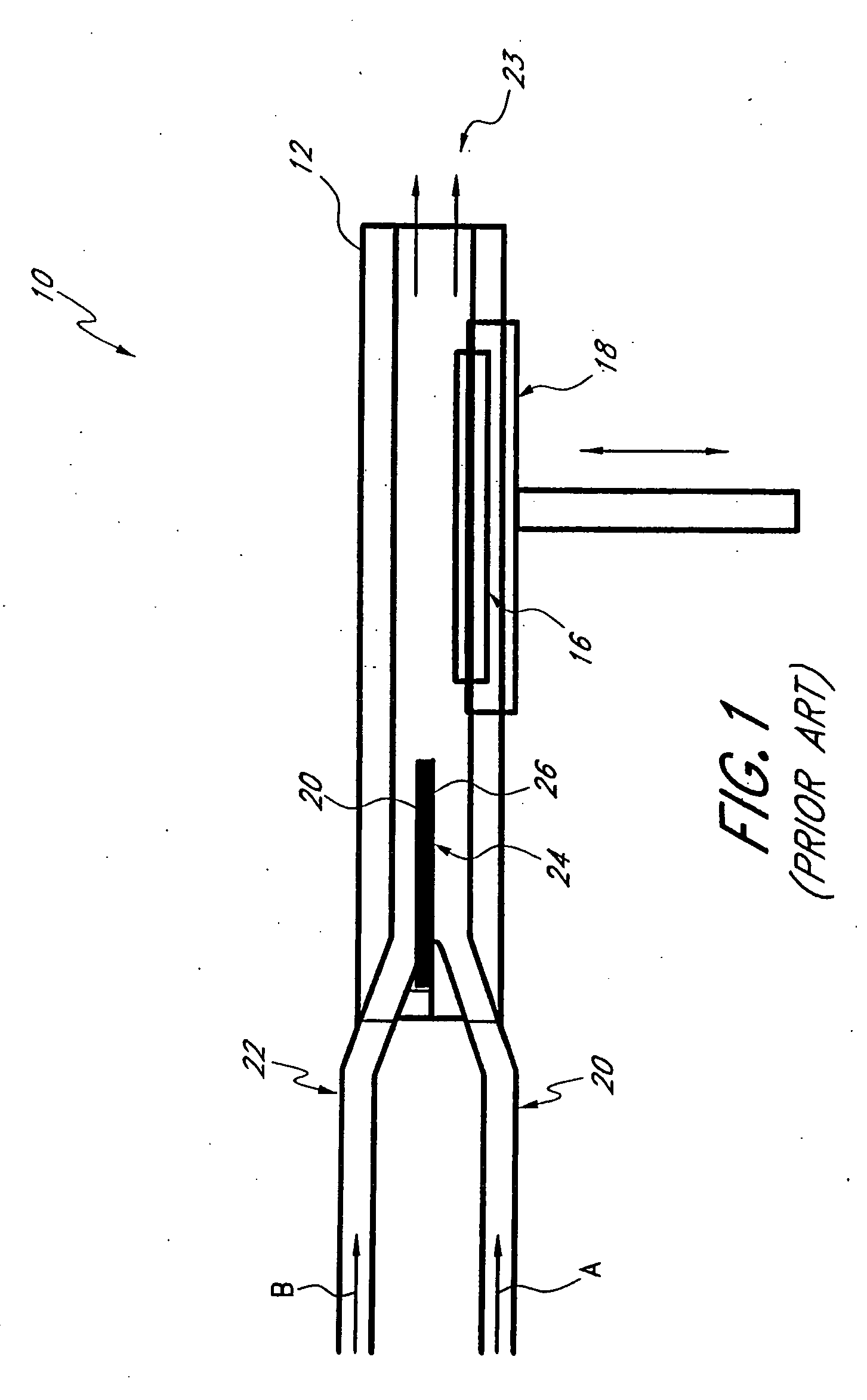

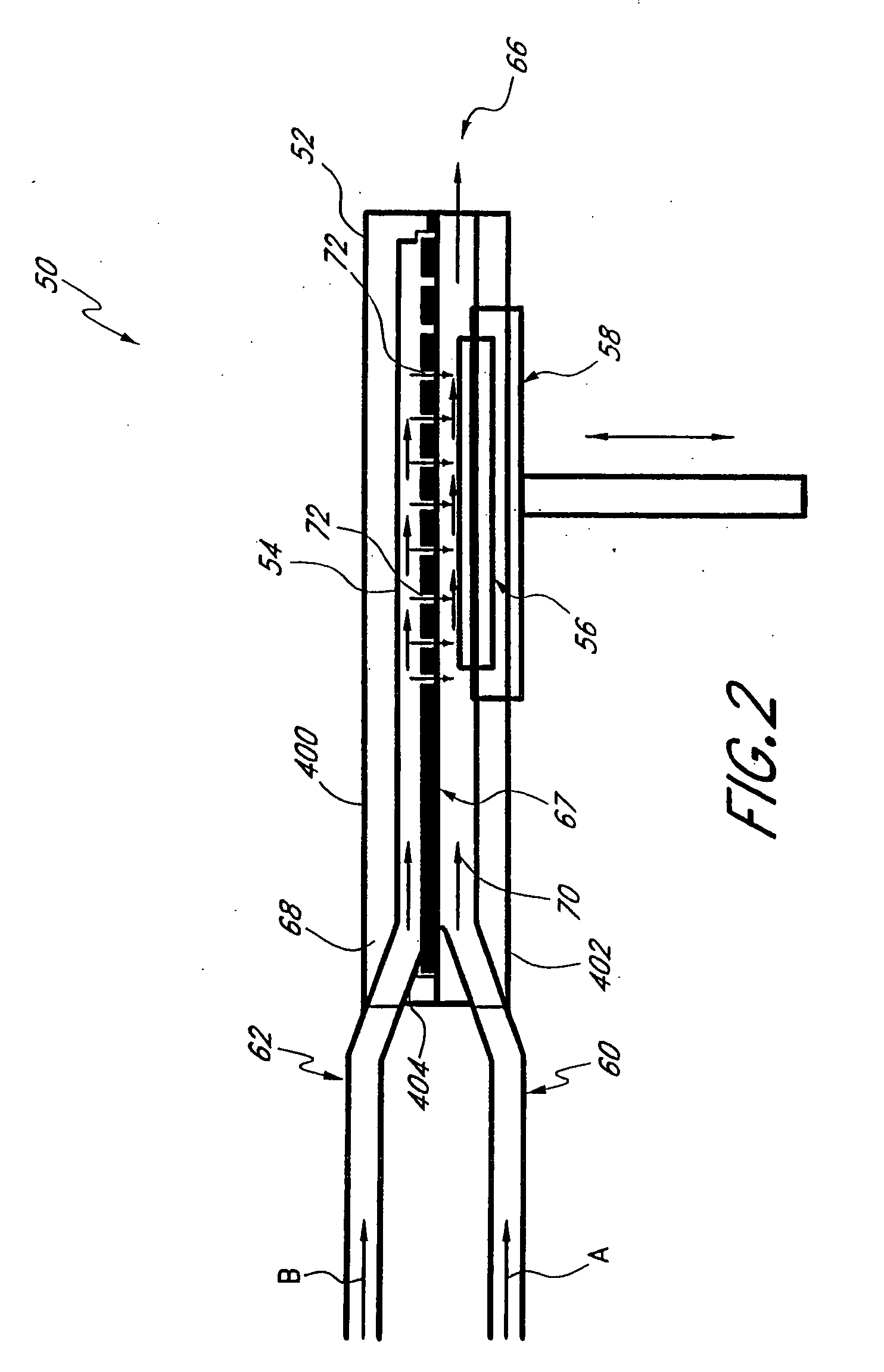

[0035]FIG. 1 schematically illustrates an exemplary prior art ALD reactor 10. The reactor 10 includes a reactor chamber 12, which defines, at least in part, a reaction space 14. A wafer or substrate 16 is disposed within the reaction chamber 14 and is supported by a pedestal 18. The pedestal 18 is configured to move the wafer 16 in and out of the reaction chamber 14. In other arrangements, the reactor can include an inlet / outlet port and an external robot with a robotic arm. The robot arm can be configured to (i) move the substrate into the reactor through the inlet / outlet port, (ii) place the substrate on the pedestal, (iii) lift the substrate from the pedestal and / or (iv) remove the substrate from the reactor through the inlet / outlet port.

[0036] In the illustrated reactor 10, two precursors, A and B, are supplied to the reaction space 14. The first precursor A is supplied to the reaction chamber 14 through a first supply conduit 20. In a similar manner, the second precursor B is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Plasma power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com