Display with micro pockets

a technology of micro-pockets and displays, applied in the field of displays, can solve the problems of the amount of electro-optic material that needs to be filled between the electrode layer and the substrate, and achieve the effects of reducing the number of layers, cost-effective production methods, and robust display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] With reference to the figures, the following detailed description explains how the invention is obtained.

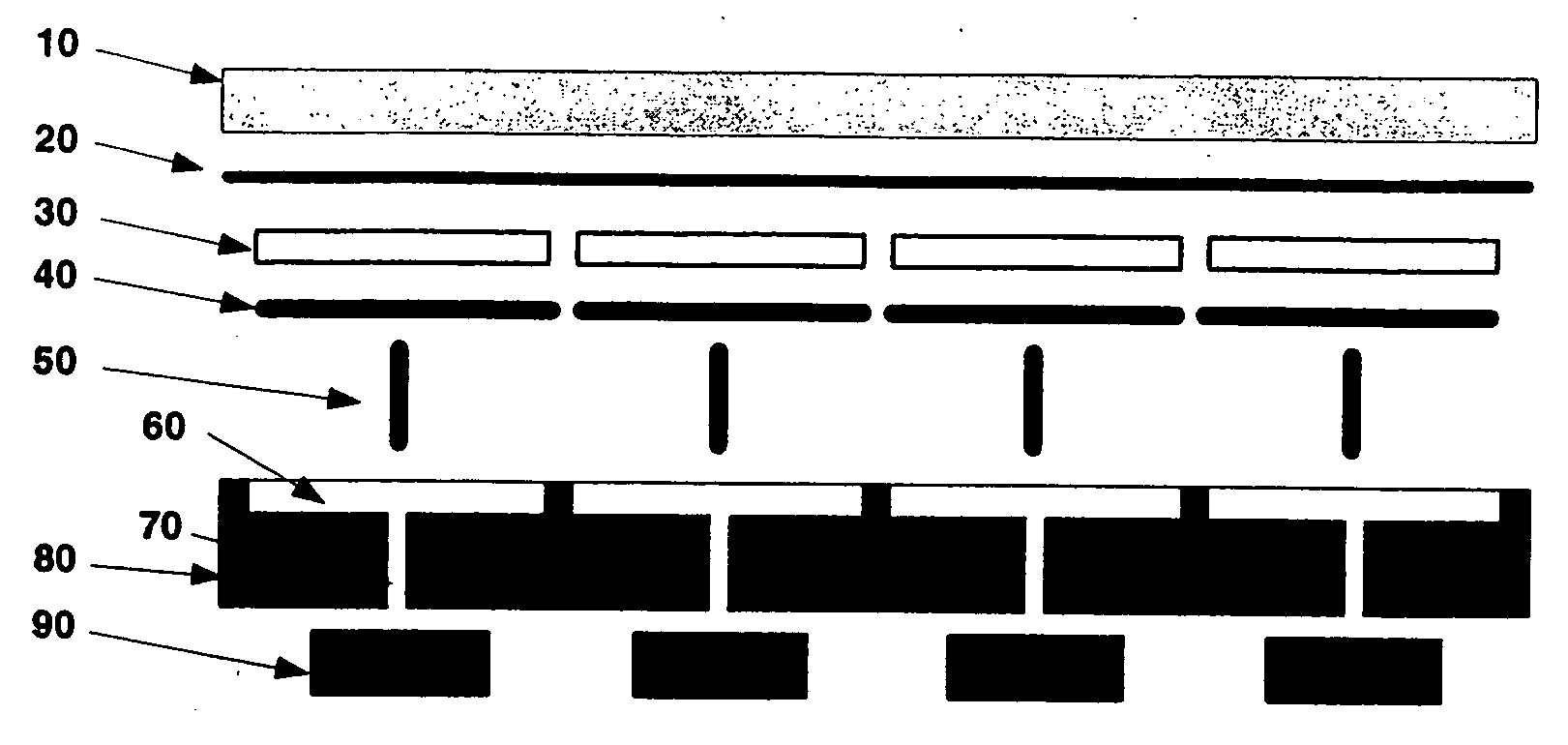

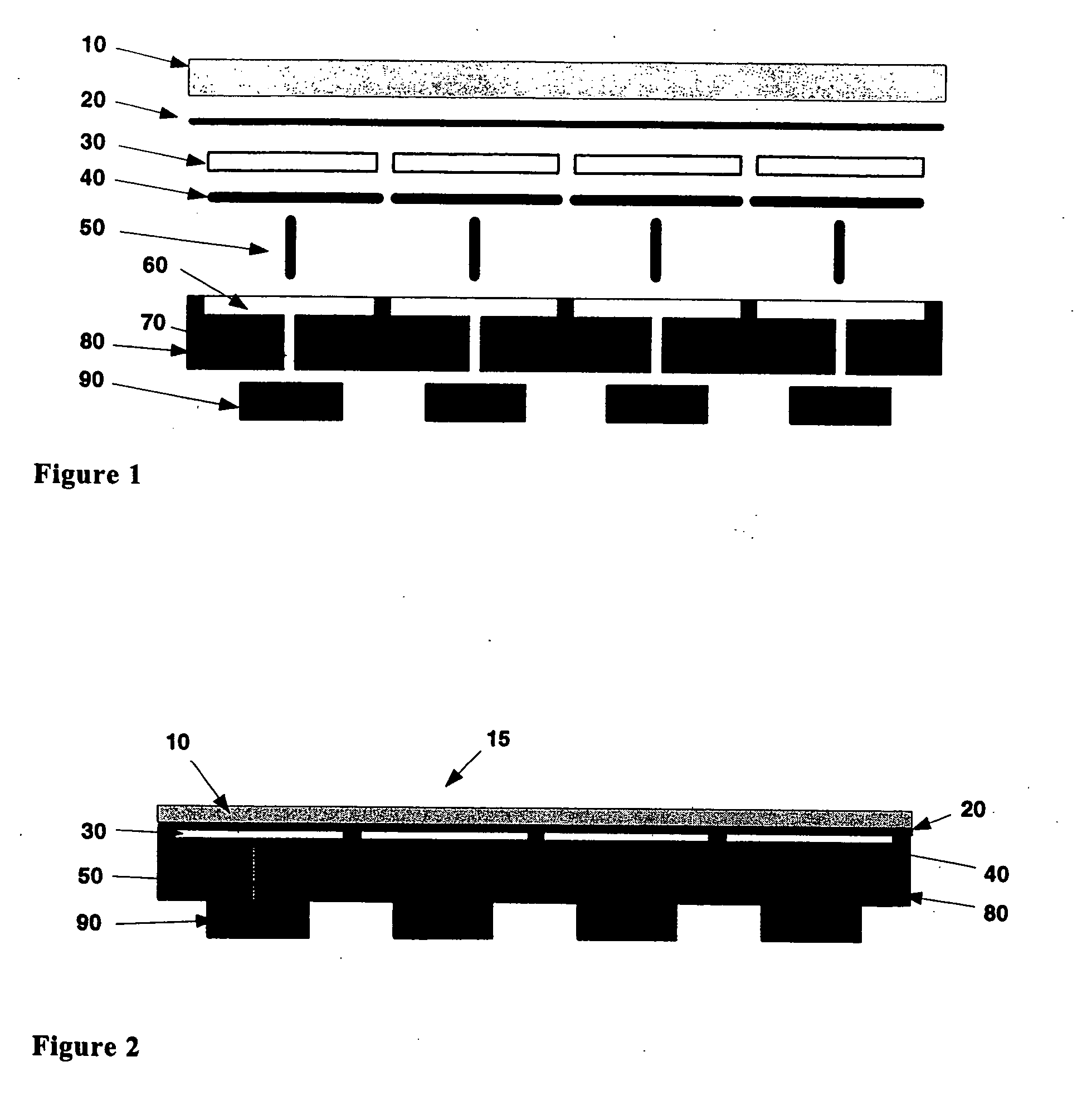

[0025]FIG. 1 shows a cross-section of the different components making the display.

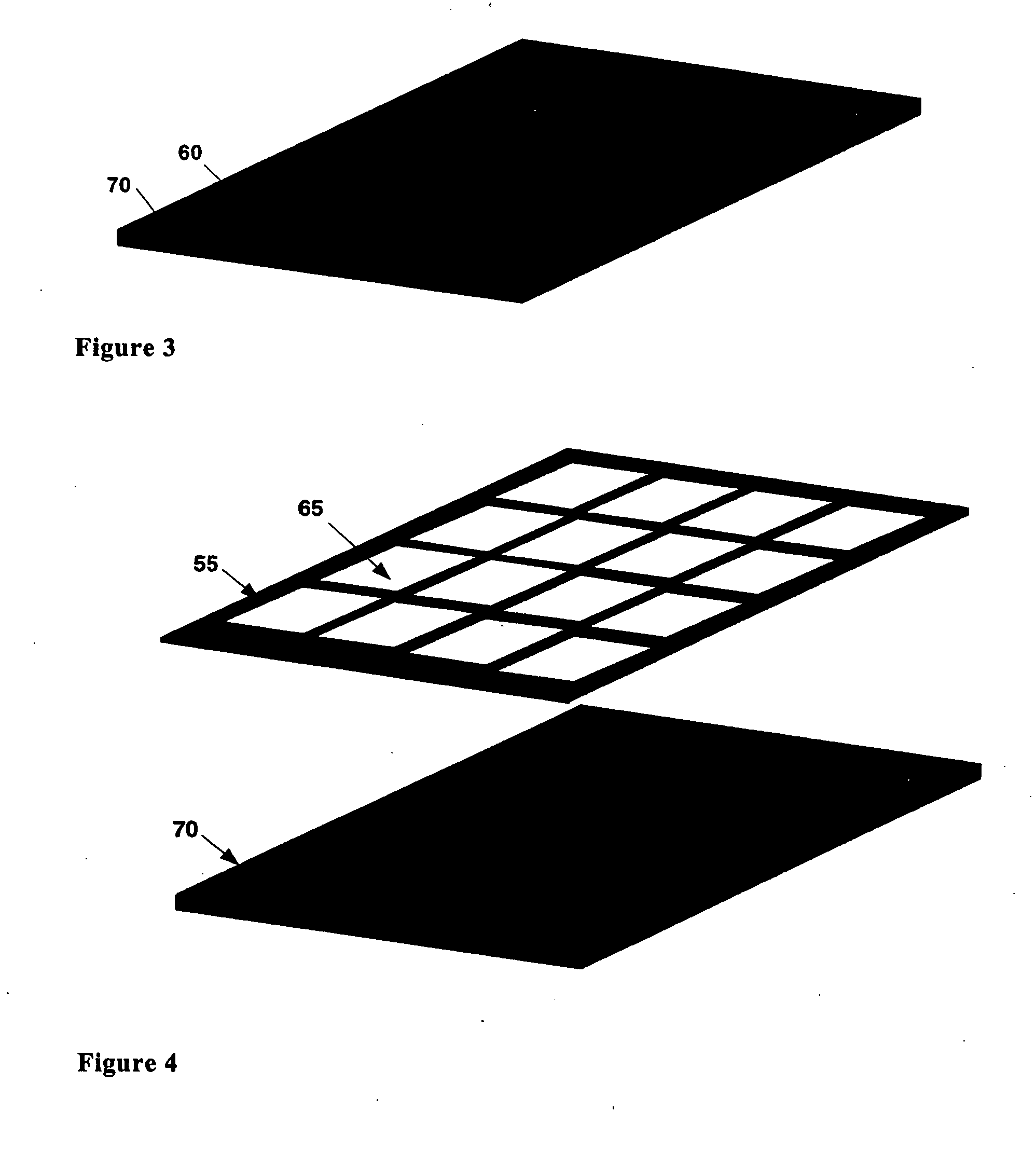

[0026] The base of the display is made of an isolating substrate 80 with small cavities 60 imprinted. These cavities 60 will make the picture elements or pixels of the assembled display. For further reference the cavities are referred to as micro pockets. The isolating substrate 80 can be made of a glassfibre composite, plastic, ceramics or another material with isolating characteristics. The micro pockets 60 may be formed by stamping, imprinting, engraving or etching in the substrate 80. After the micro pockets 60 are established, holes 70 in the centre of each micro pocket 60 are made. These holes 70 will in turn provide for an electrical connection between the underside of the substrate and each pocket 60. This connection will be established when a conductive material 40, 50 is applied t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparent conductive | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com