Work Platform tool & material shelf

a technology for tools and materials, applied in the field of tool and material shelves, can solve the problems of limited size and use, tools and materials are stored on the floor, and the use of mobile lift machines is limited, so as to achieve convenient interchange, simple and inexpensive design, and the effect of increasing volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

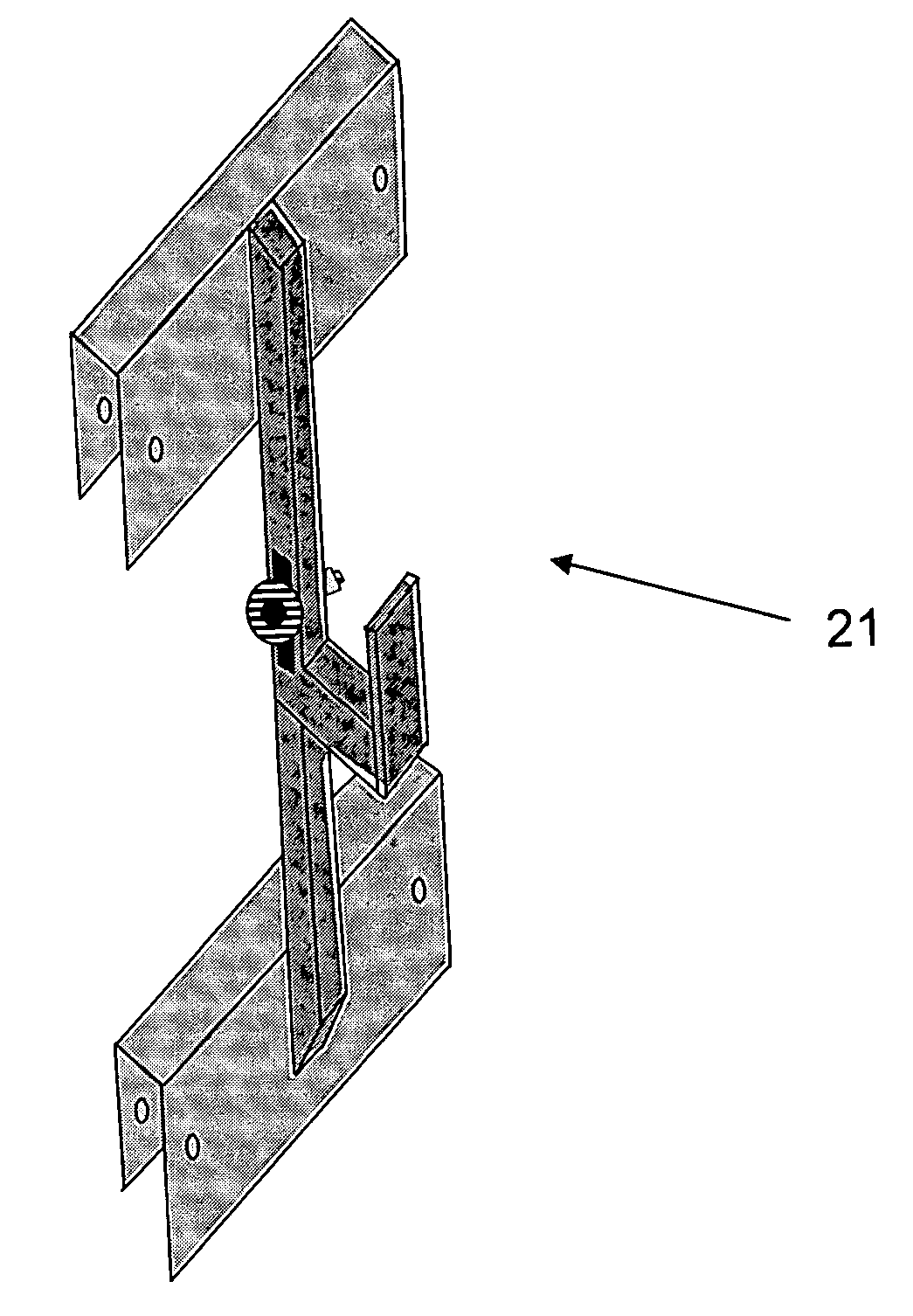

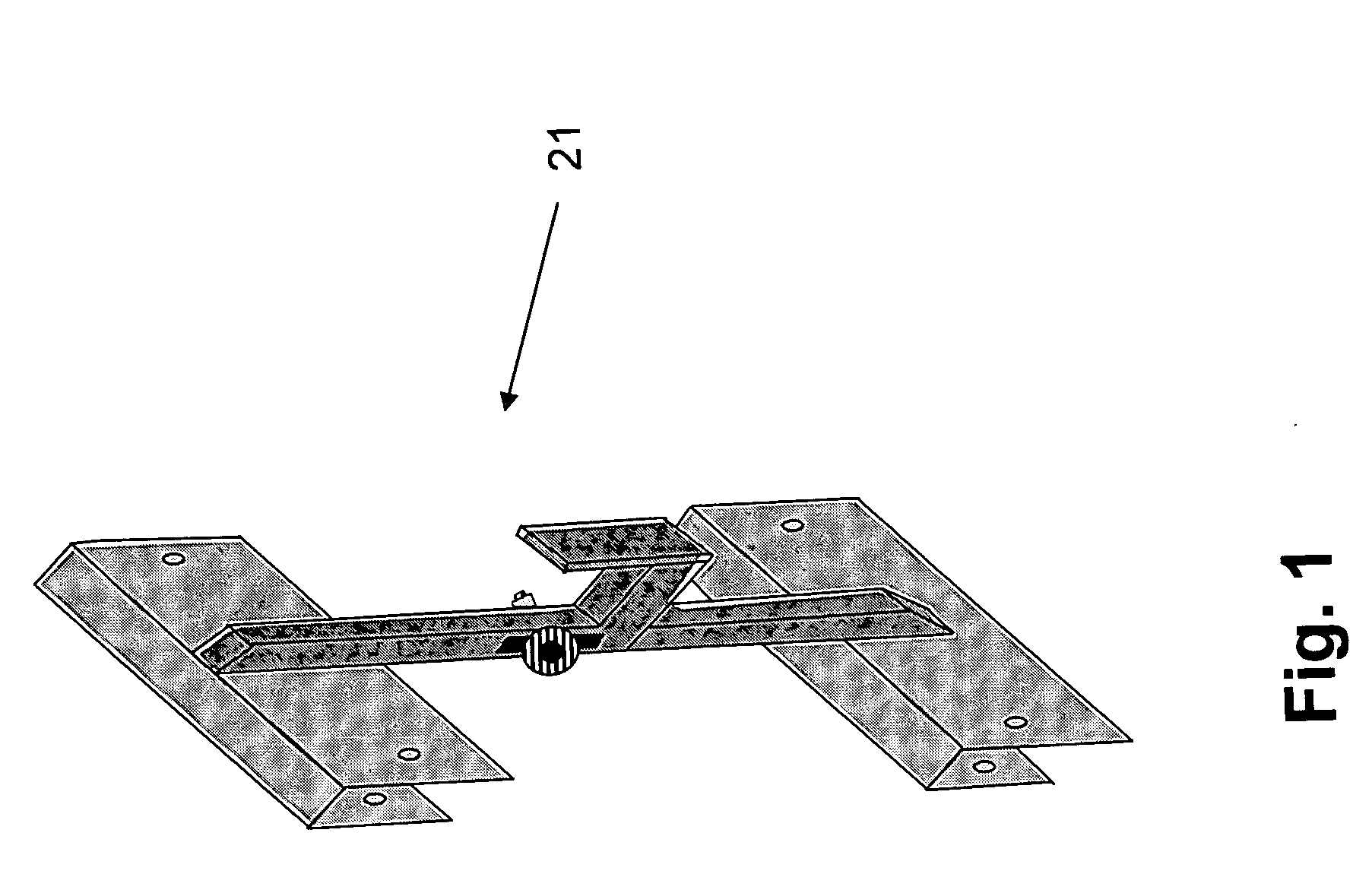

embodiment 21

[0099]FIG. 1 is a PERSPECTIVE View of the preferred embodiment of the adjustable support for the Tool and Material shelf for mobile work platforms. This is the Universal (flexible) embodiment 21 that may adjust to various lifts and work platforms from various manufacturers.

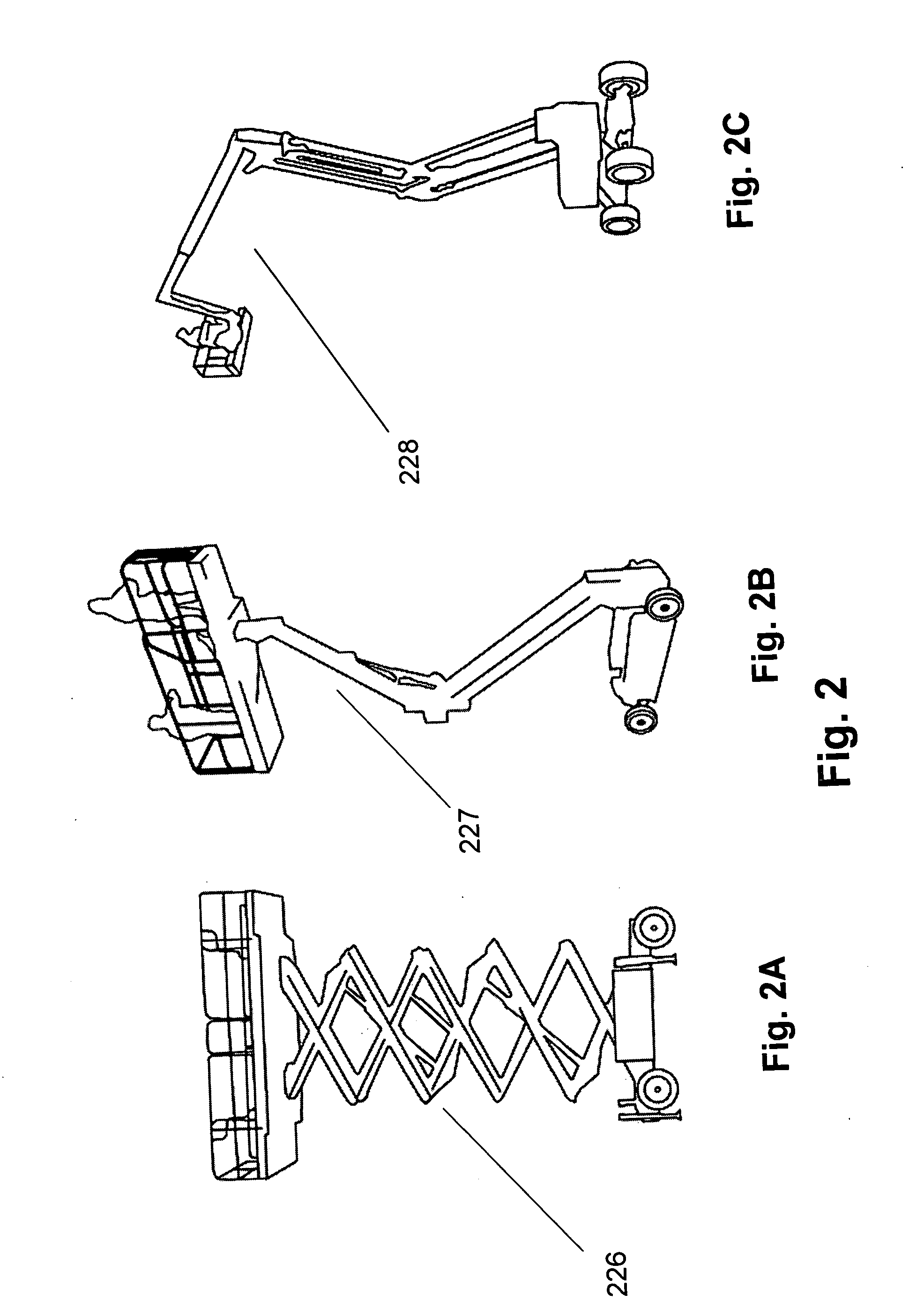

[0100]FIG. 2 is a series of perspective views of various types of lift machines with which the Tool and Material shelf is utilized. FIG. 2A is a PERSPECTIVE View of a mobile aerial lift machine that is commonly called a scissors lift 226. Next, shown as FIG. 2B is another mobile aerial lift machine, an articulated lift 227. In FIG. 2C an articulated lift machine is combined with a boom basket 228. All three pictures are to demonstrate the wide variation of work platforms and the need for a universal shelf device as the Present invention.

[0101]FIG. 3 shows a sketch of a typical work platform 312. Note that the width w and the height h vary between manufactures, between types of lifts, and between specific sizes or...

embodiment 45

[0119]FIG. 12 shows material holding device 45 similar to the ones in FIGS. 10 and 11. Here the connection is strictly a Pinned device as an Alternative Embodiment 45 and incorporates the fastening of the vertical support post 24 utilizing multiple lock pins and cotter keys 28. This is not the preferred way since this embodiment limits some of the vertical flexibility and adjustability of the device. It may be quicker to set-up with a custom-made lift machine and may be appropriate for some specific applications.

[0120]FIG. 13 shows a secure Alternative Embodiment for attaching the trays in a quickly removable manner. This is an assembly sketch similar to the one in FIG. 8, above, and includes the Isometric view FIG. 13A; Top view FIG. 13B; Front view (above rail line 51) FIG. 13C; the Side view (of above rail line 51) FIG. 13D; the Front view (below rail line 51) FIG. 13E; and the Side view (below rail line 51) FIG. 13F.

[0121] In this Alternative Embodiment the attachment of trays,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com