Adjuster for elevated floor

a technology for adjusting devices and floors, applied in the direction of screws, threaded fasteners, mechanical equipment, etc., can solve the problems of inability to reduce the floor, inconvenient adjustment for use of the floor, and waste of spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

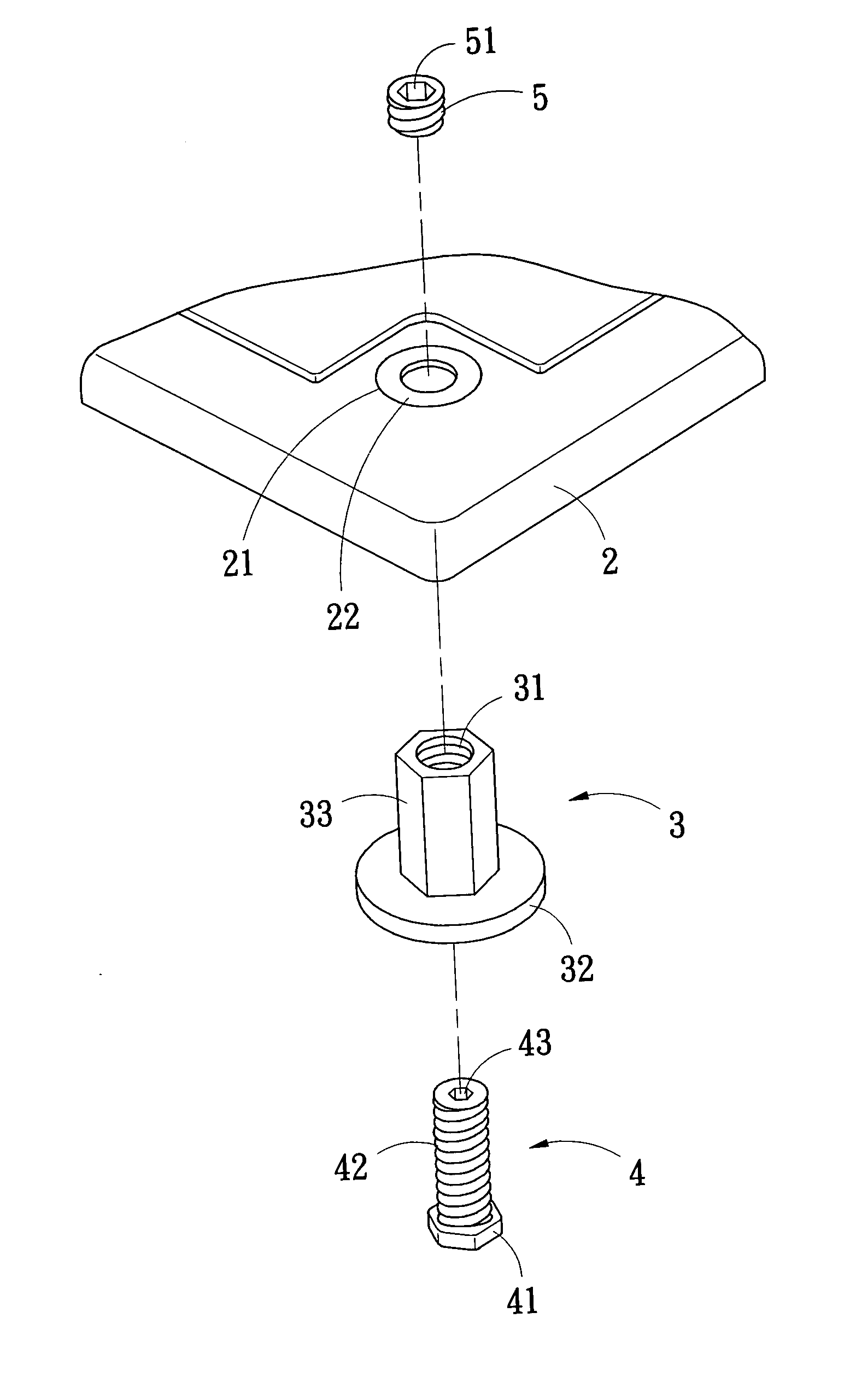

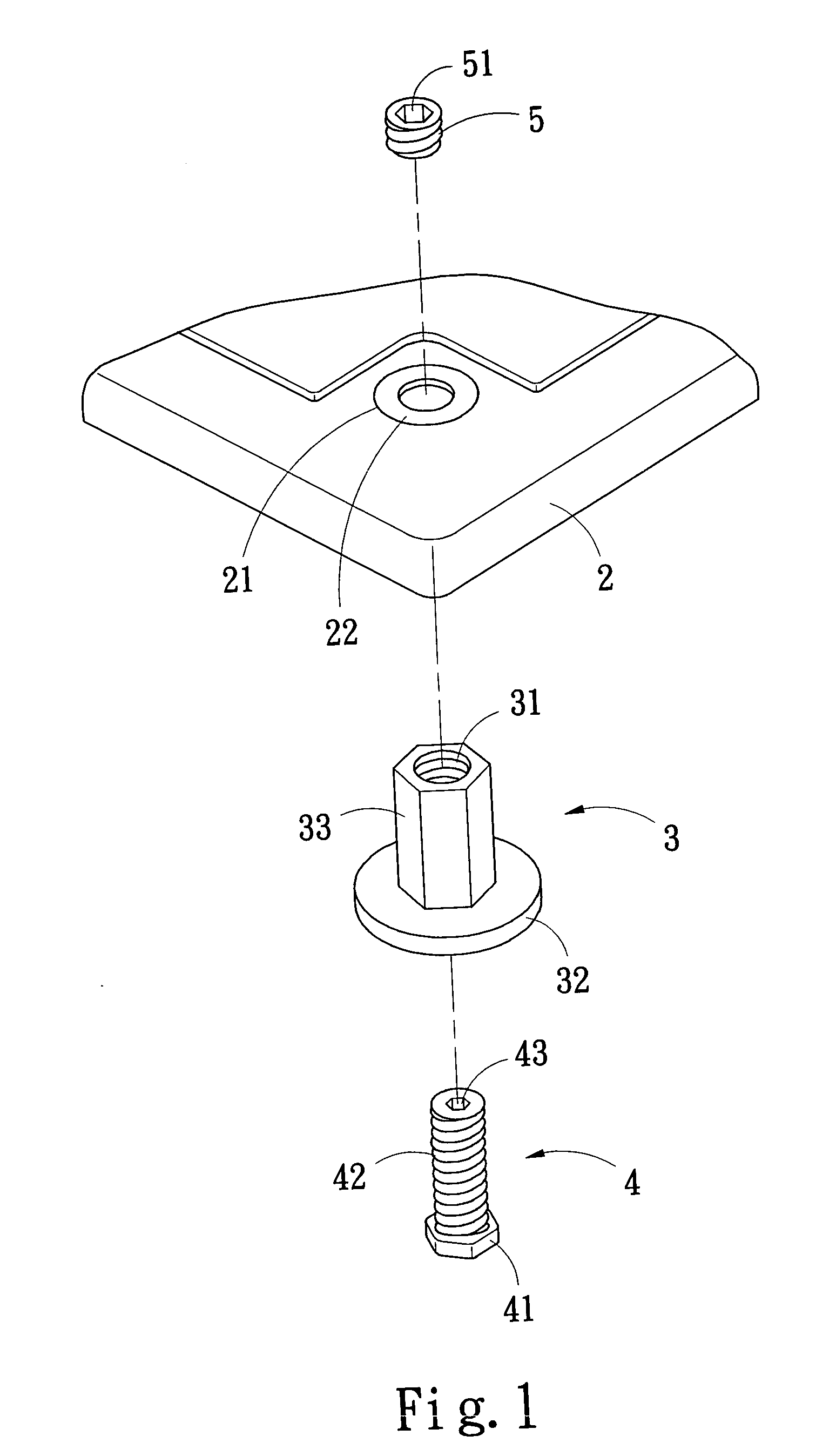

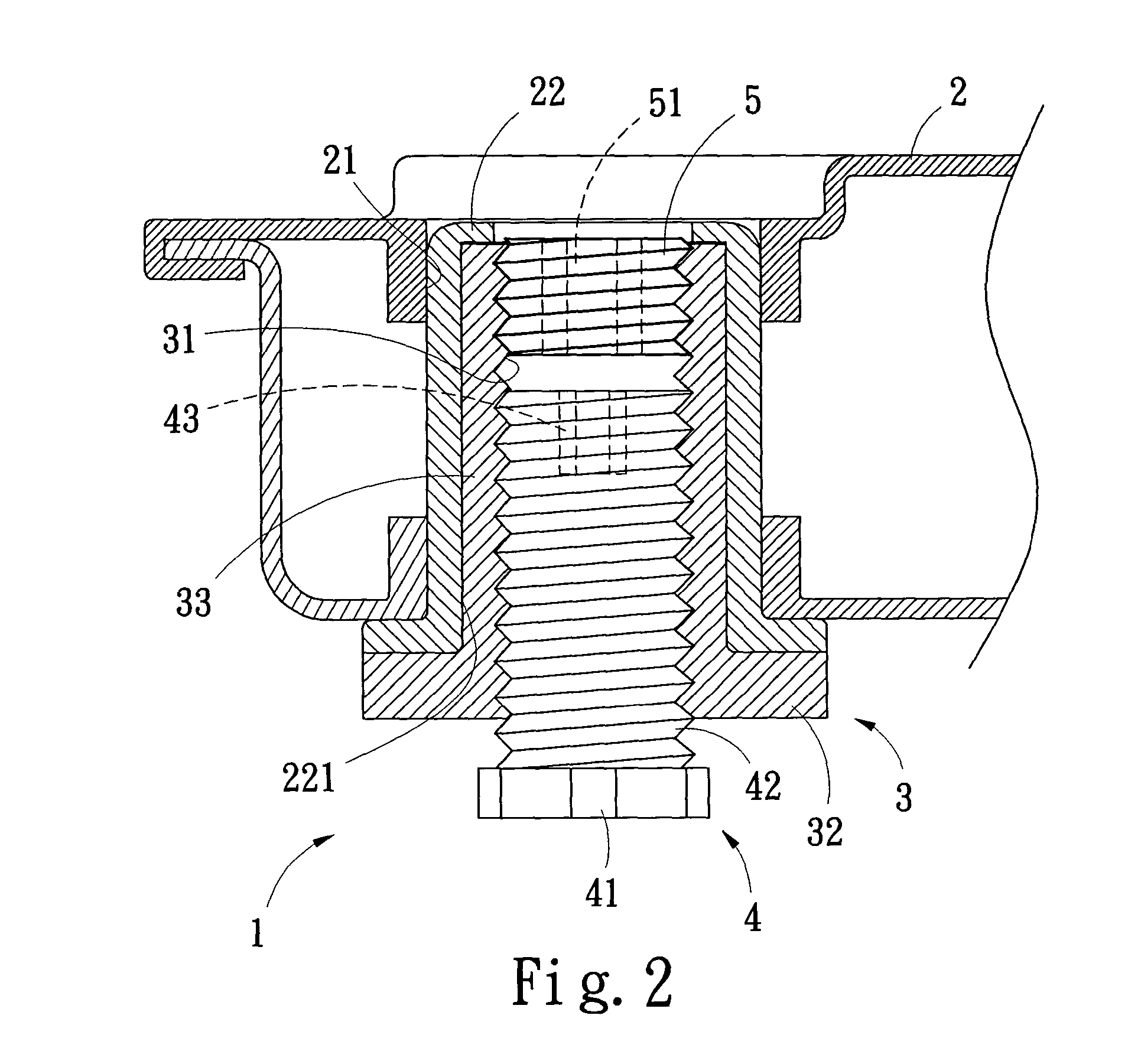

[0019] Referring firstly to FIGS. 1 and 2 showing a preferred embodiment of an adjuster 1 for an elevated floor 2 of the present invention, the adjuster 1 is connected with a connecting hole 21 provided on the elevated floor 2. It comprises mainly: a threaded pipe 3, a footing seat 4 and a fixing screw 5.

[0020] A bush 22 is provided between the threaded pipe 3 and the connecting hole 21 on the elevated floor 2, and has an inner hexagonal hole 221. The threaded pipe 3 is in the form of an inversed “T” and has an inner thread 31, and has on the bottom end thereof a circular base 32. The upper portion of the threaded pipe 3 is a hexagonal stub 33 for connecting with the inner hexagonal hole 221 of the bush 22.

[0021] The footing seat 4 has a base 41 for standing on the ground, the footing seat 4 is provided on the external upper end thereof with an external thread 42 for threading and connecting with the threaded pipe 3, and the footing seat 4 further has an hexagonal adjustment hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com