Bowler's Positive Control System And Method

a control system and positive technology, applied in the field of bowllers, can solve the problems of not being solved by any device, and the difficulty of giving the combined rotation to the ball in any consistent manner, and achieve the effect of positive control over the alignment of the ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

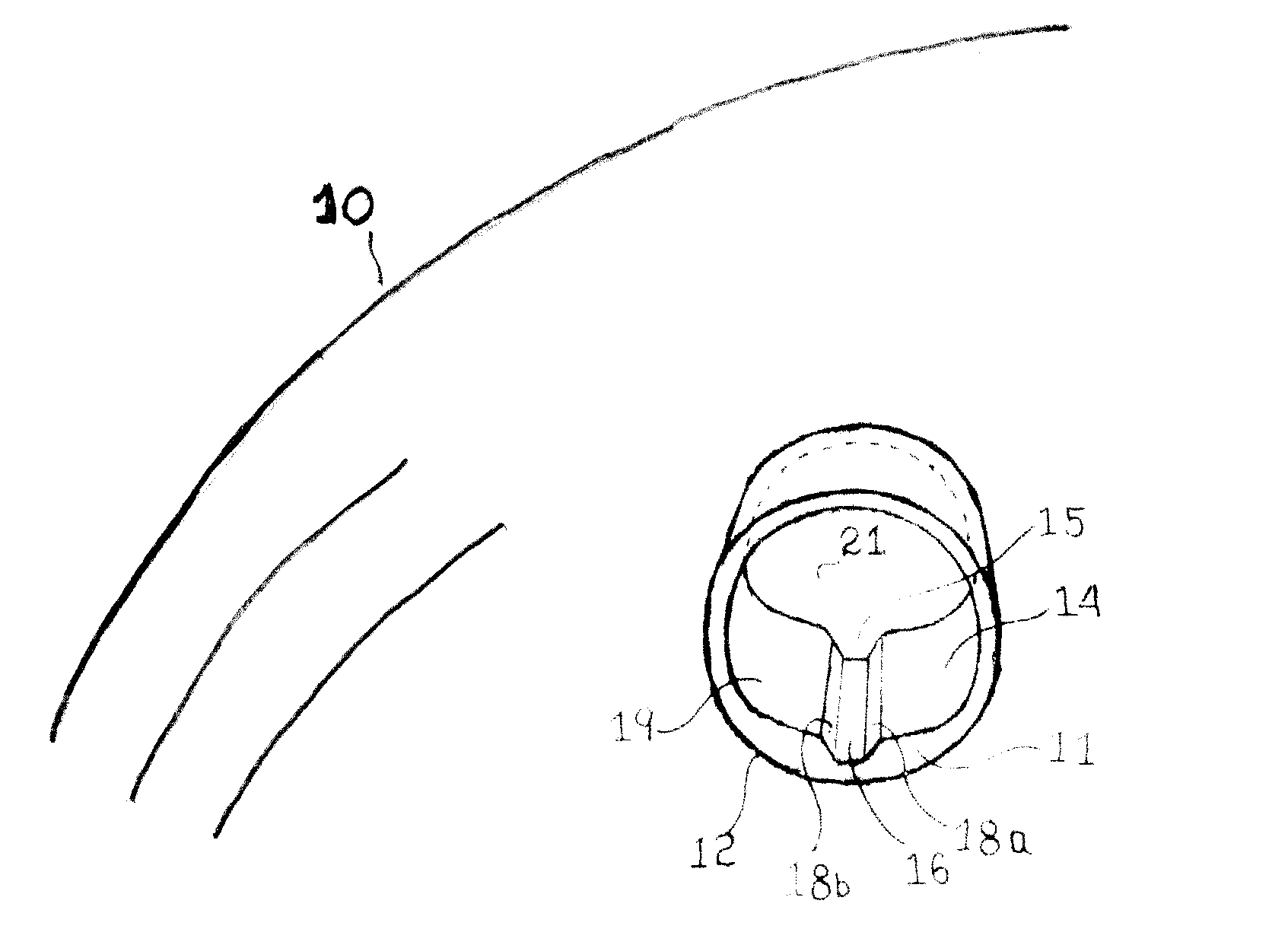

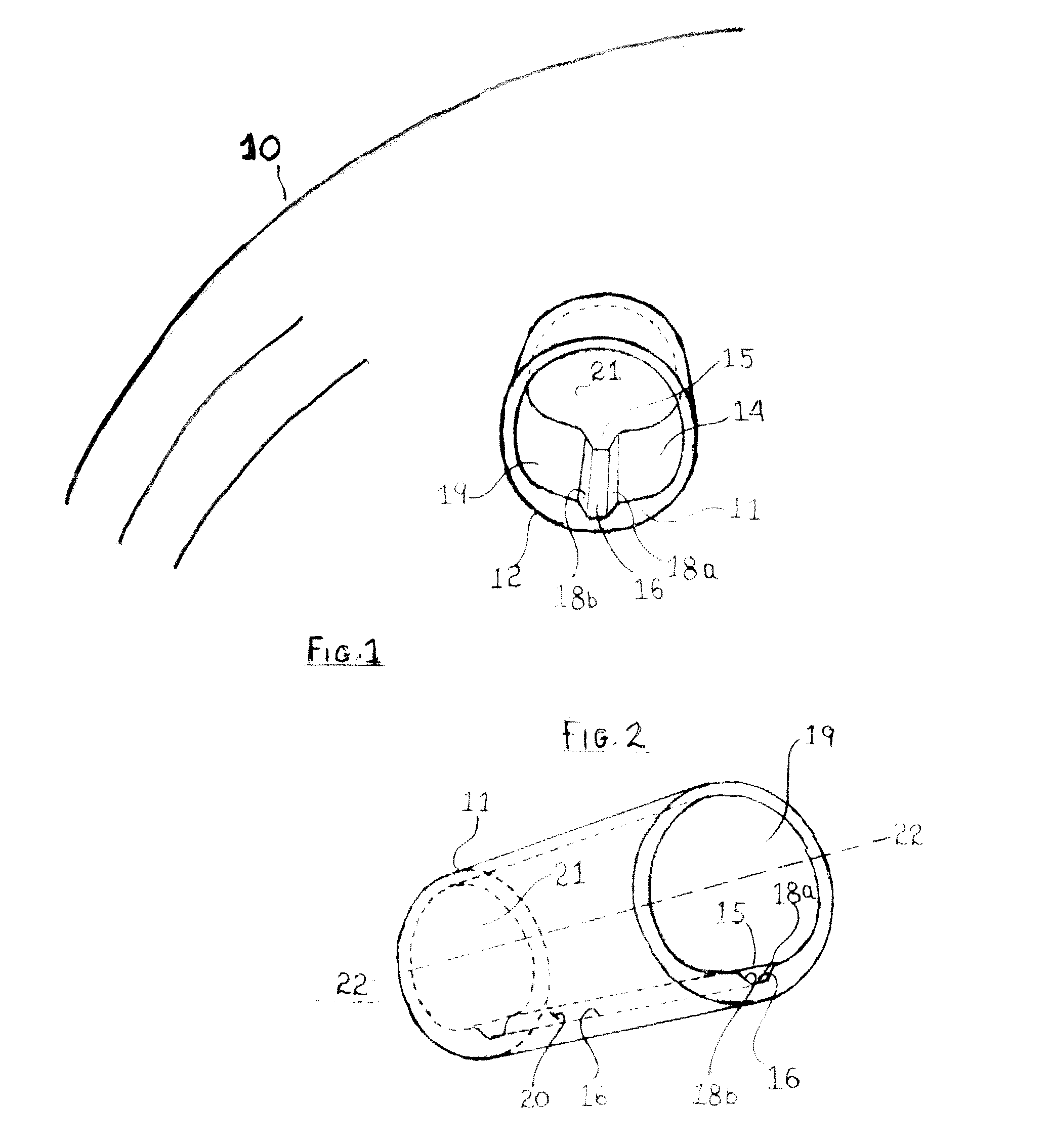

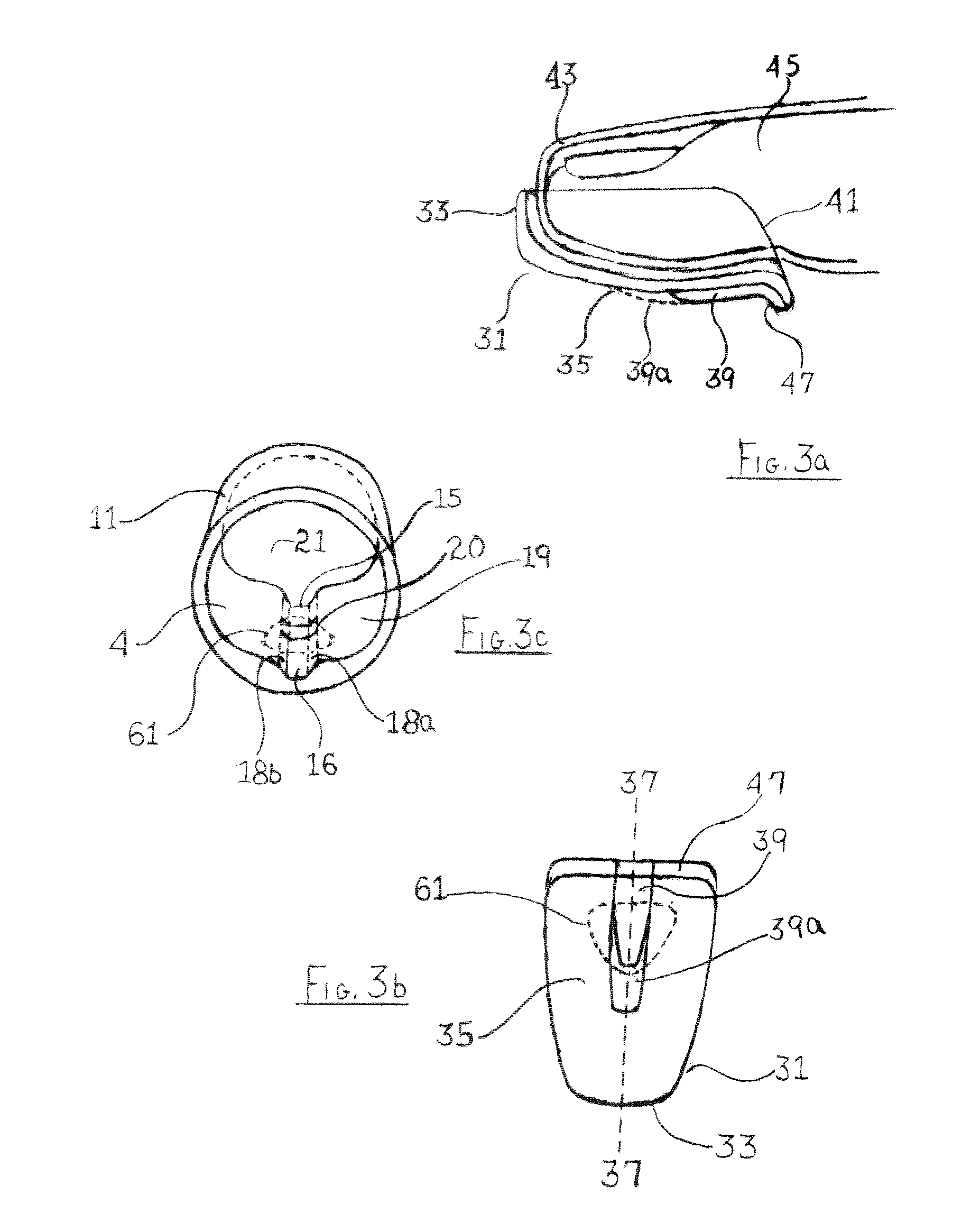

[0026] The invention as described by the disclosed inventive principles comprises matching or interlocking surfaces in the area of contact made by the interior surface of a bowling ball finger hole and finger pad cover mounted on a bowler's middle finger pad for achieving positive control when used in releasing the ball and imparting lift to the ball on its release.

[0027]FIG. 1 shows a bowling ball 10, in partial view, with a finger hole insert 11 when inserted into finger hole 12 and with the insert 11 shown partially in phantom. As would be understood by those skilled in the art, the disclosed invention and the inventive principles may be used in a preferred embodiment with a finger hole insert 11 or may be applied directly on the interior surface of the finger hole 12. The finger hole, or finger hole insert inner surface 14, as shown includes a three dimensional surface. shown generally by numeral 15 on insert inner surface 14, and with base 16 and side walls 18a and 18b, defini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com