Optical fiber grating, optical fiber grating manufacturing method, and optical fiber grating manufacturing apparatus

a technology of optical fiber grating and manufacturing method, which is applied in the direction of cladded optical fibre, instruments, optical elements, etc., can solve the problems of difficult to guarantee a high yield and maintain the stability of optical properties in this environment over the long term, and achieve precise control of optical properties, modulation or fluctuation of optical propertying, and the effect of extending the optical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

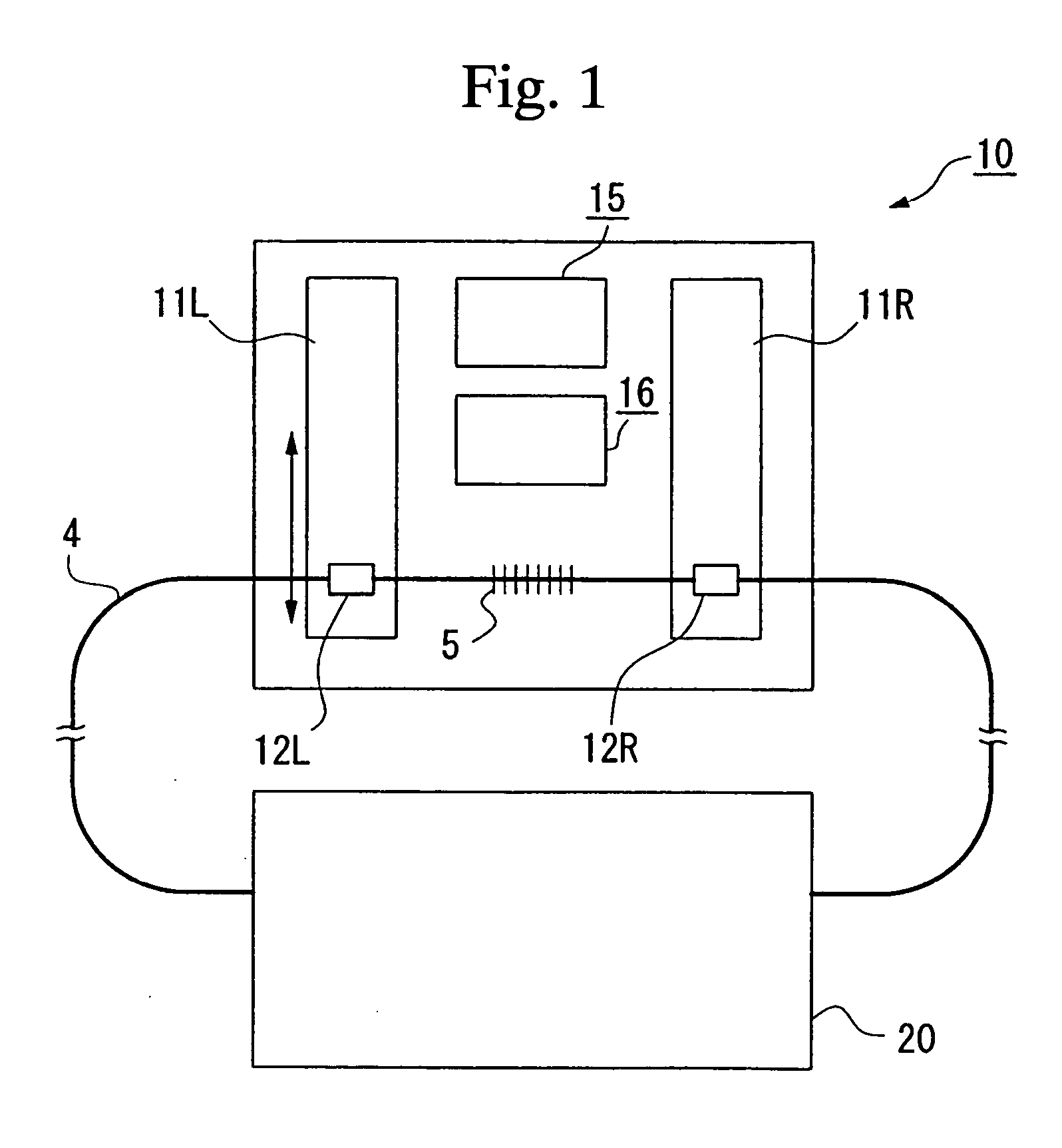

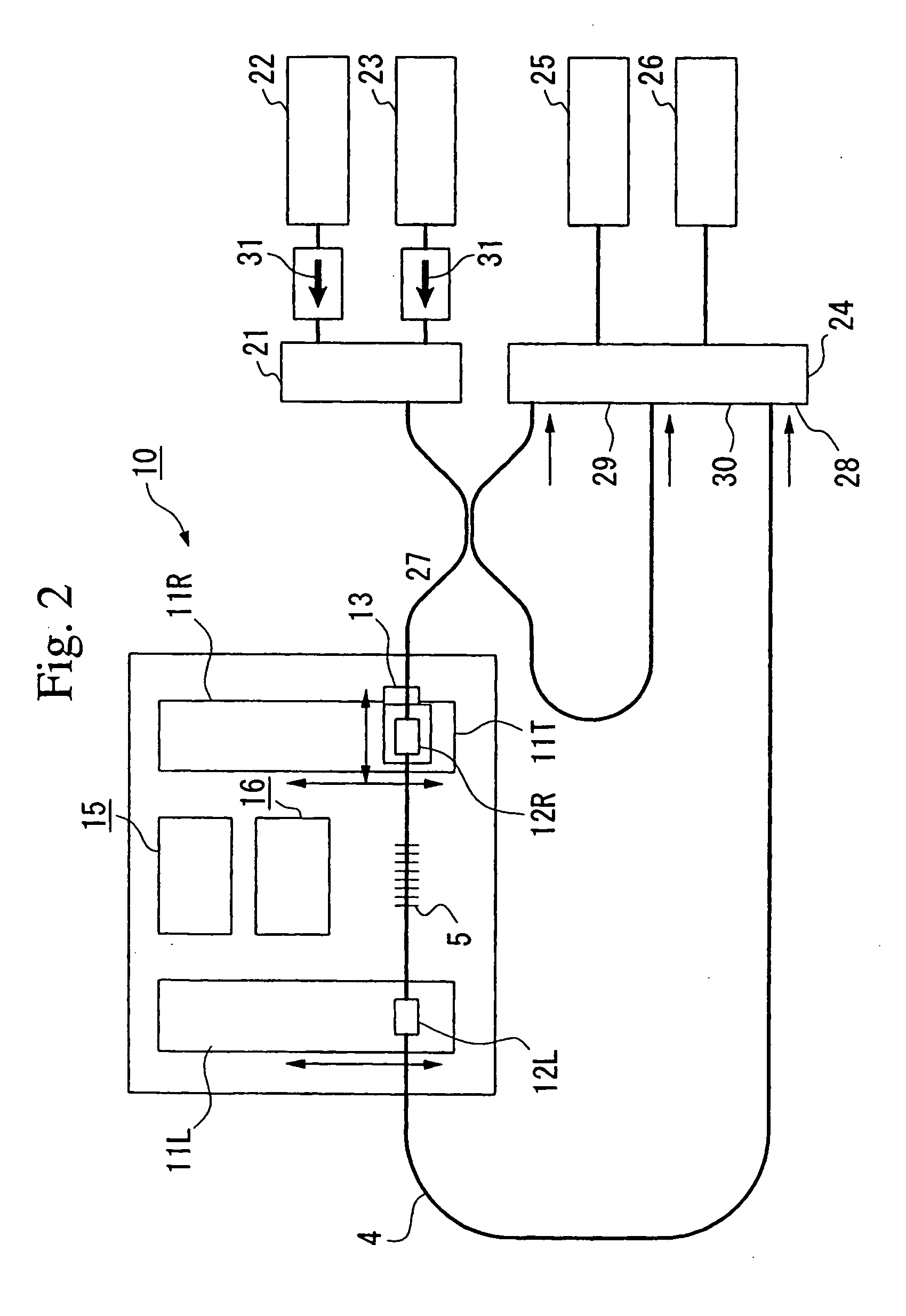

[0041] Examples of the optical fiber grating, the optical fiber grating manufacturing method, and the optical fiber grating manufacturing apparatus of the present invention will be explained referring to FIG. 1 to FIG. 8.

[0042] First, an example of the optical fiber grating manufacturing apparatus of the present invention will be explained.

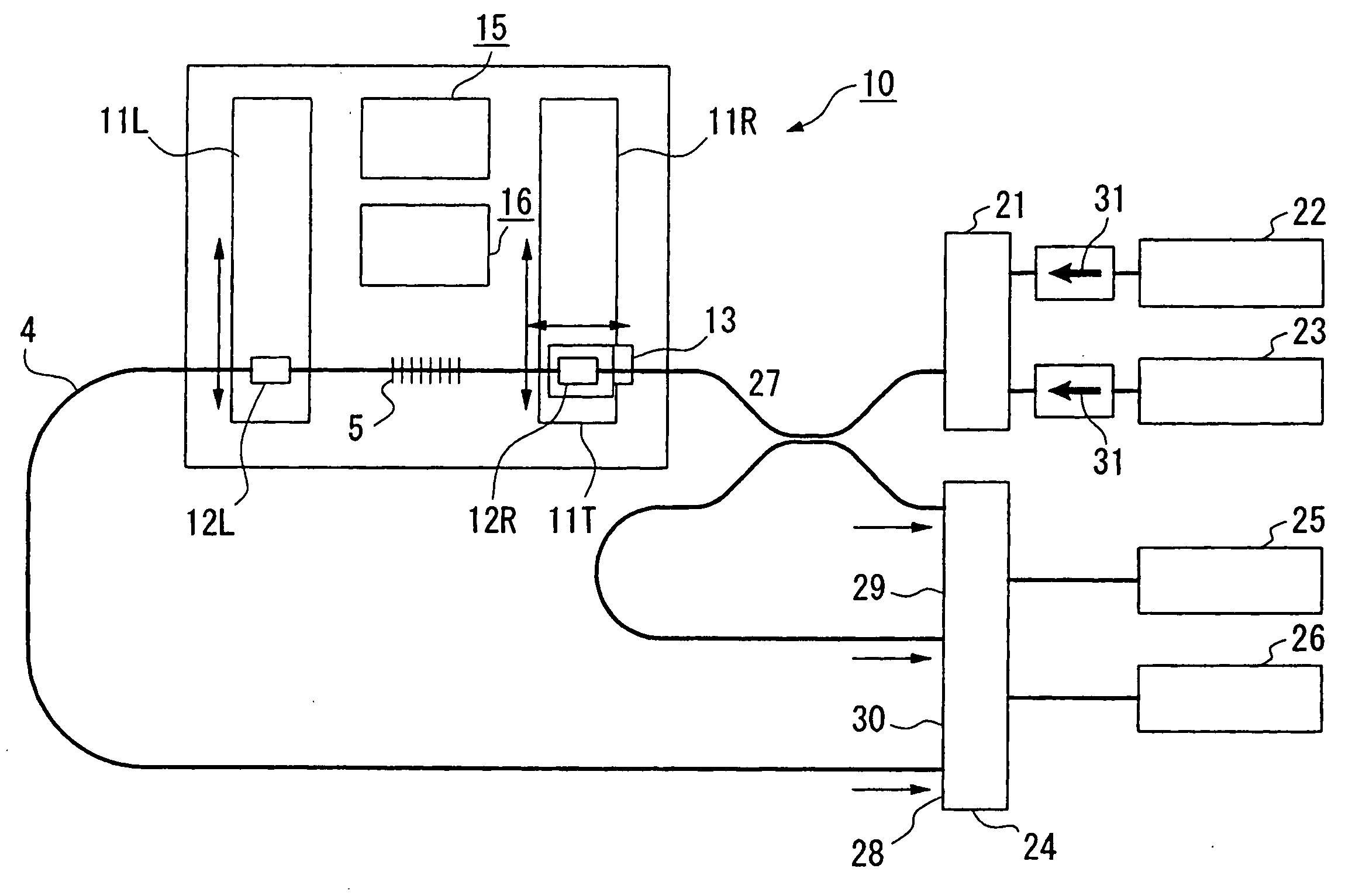

[0043]FIG. 1 is a schematic drawing for explaining the optical fiber grating manufacturing apparatus of the present invention, and as an embodiment, shows the case therein the optical fiber grating part is formed.

[0044] In FIG. 1, the optical fiber 4 is anchored by the fiber clamps 12R and 12L disposed on the automatic stages 11R and 11L provided on both sides of the manufacturing apparatus 10. At the center of the manufacturing apparatus 10, a heating apparatus 15 such as a heater and an ultraviolet irradiation apparatus 16 are disposed, the optical fiber is moved vertically parallel to the ultraviolet irradiating apparatus 16 and the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com