Reversible plate holder

a plate holder and reversible technology, applied in the field of plates holder, can solve the problem that the liner cannot be reversible, and achieve the effect of avoiding the problem of reversible orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 29

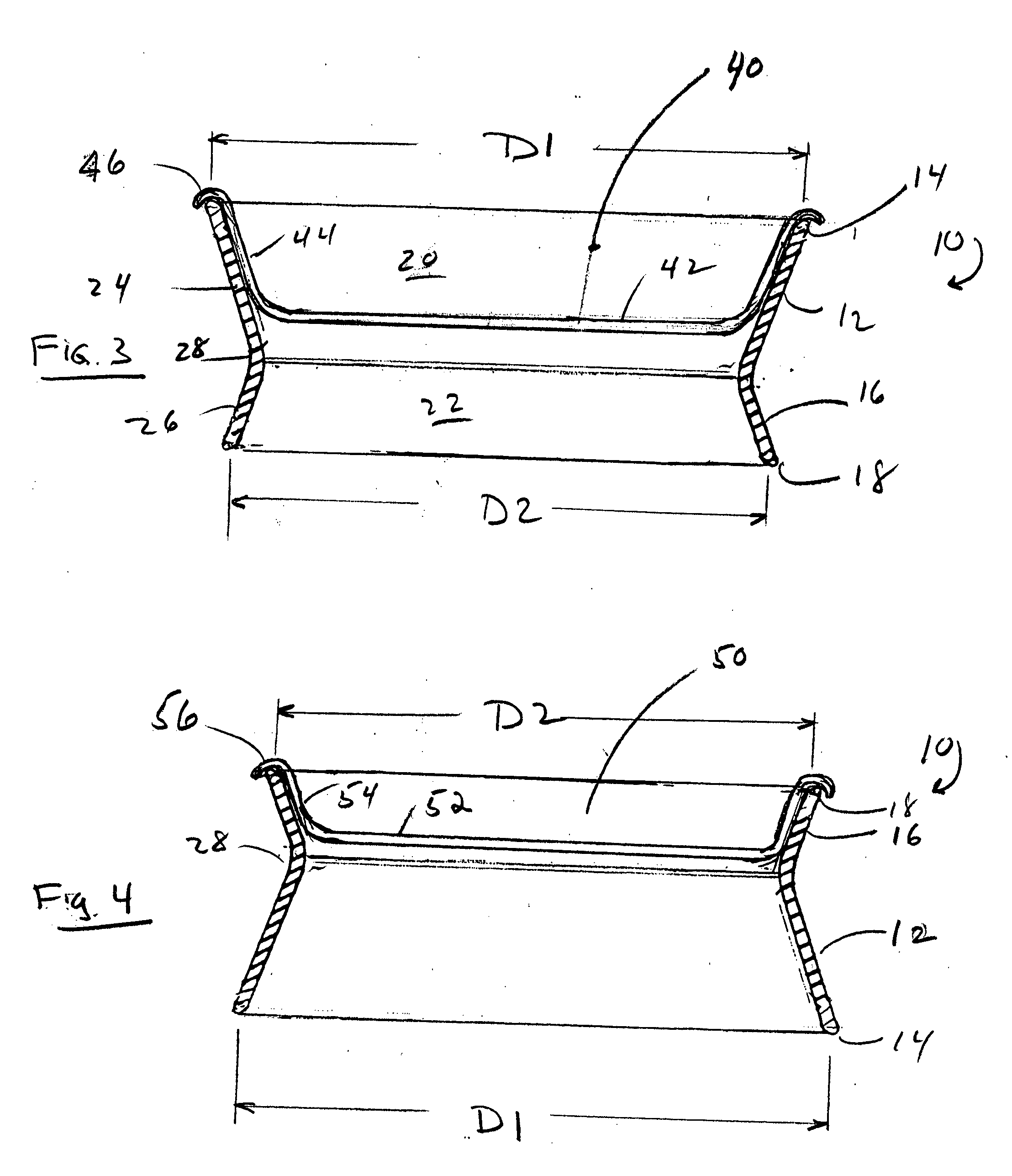

[0038]FIGS. 5 and 6 show an embodiment 29 generally similar to that of FIGS. 1-4, but where the inner surfaces 30A, 30C and 30B of the top and bottom conical walls and of the neck respectively define a continuous convex curve. These walls are of generally uniform thickness, and thus, the outer surfaces 31A, 31B and 31C define a corresponding continuous concave surface. FIG. 5 shows the plate holder in upright position with its top edge 32 supporting a plate, and FIG. 6 shows the plate holder in inverted position with its bottom edge 33, now on top, supporting a plate.

[0039] The curvature as shown may vary, so long as there remain generally conical walls at the top and bottom. This particular embodiment with its smooth and continuously curved inner and outer walls, has an unusual and modern appearance, while still providing all the structural and functional benefits of the basic invention.

embodiment 60

[0040]FIGS. 7 and 8 show a further embodiment 60 of the new reversible plate holder where the upper part 62 and lower part 64 define a single conical shape having essentially straight and uniform thickness walls from top 66 to bottom 68. With this plate holder plates of different diameter could be supported at the opposite ends, as shown in connection with FIGS. 1-4. In this embodiment the height and diameter dimension are generally similar to those of the article in FIGS. 1-4, while the overall shape of a simple straight wall is considerably different.

embodiment 70

[0041]FIGS. 9 and 10 show a further embodiment 70 of the new reversible plate holder which is a solid base whose outside solid peripheral walls 72 are round with top 74 and bottom 76 respectively. Within the top is a conical recess 78 of a first diameter, and within the bottom is a concentric conical recess 80. This plate holder 70 is reversible by inverting the base similarly as with the plate holder of FIGS. 1-4. The solid walls add bulk and weight which enhances stability regardless of which end is positioned downward.

[0042]FIGS. 9 and 10 are representative of a solid reversible plate holder having opposing co-axial conical recesses as seen in FIG. 4 or 5, and having any outer shape which may be for example, round, oval, rectangular, square or octagonal that are concentric with the conical recesses, or may be non-concentric therewith. Also, the conical top and bottom recesses are not required to be co-axial.

[0043] In the various reversible plate holders illustrated, if the top a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com