Catalytic distillation hydroprocessing

a catalytic distillation and hydroprocessing technology, applied in the direction of hydrocarbon distillation, hydrocarbon oil cracking, bed hydrotreatment process apparatus, etc., can solve the problems of large hydrocarbon molecules cracking into middle distillates, large hydrocarbon bonds will crack, and large hydrocarbon bonds may crack into lighter hydrocarbons, so as to reduce excess naphtha and lighter hydrocarbons production, reduce the efficiency and output of the hydroprocessing unit, and minimize unwanted secondary cracking of hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

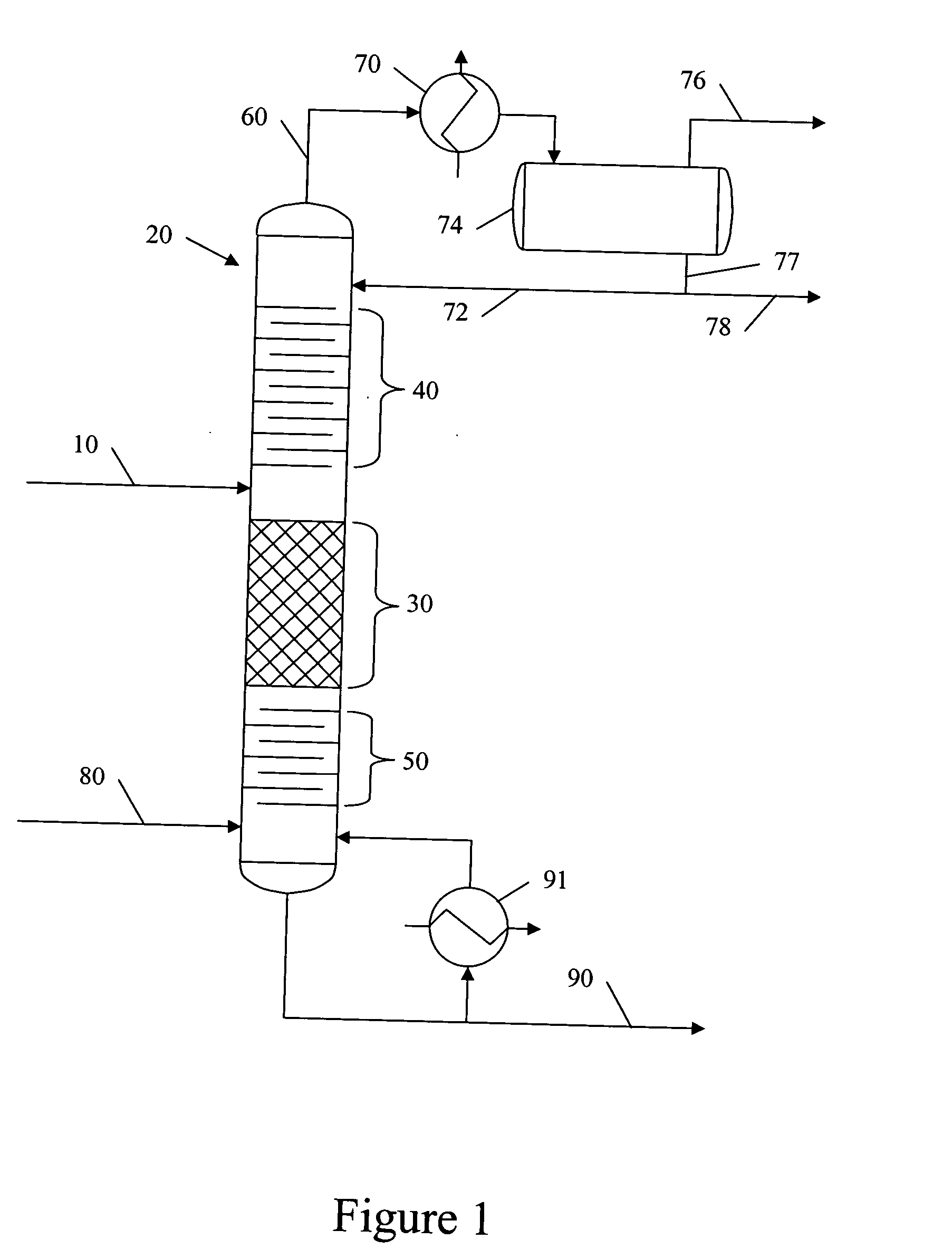

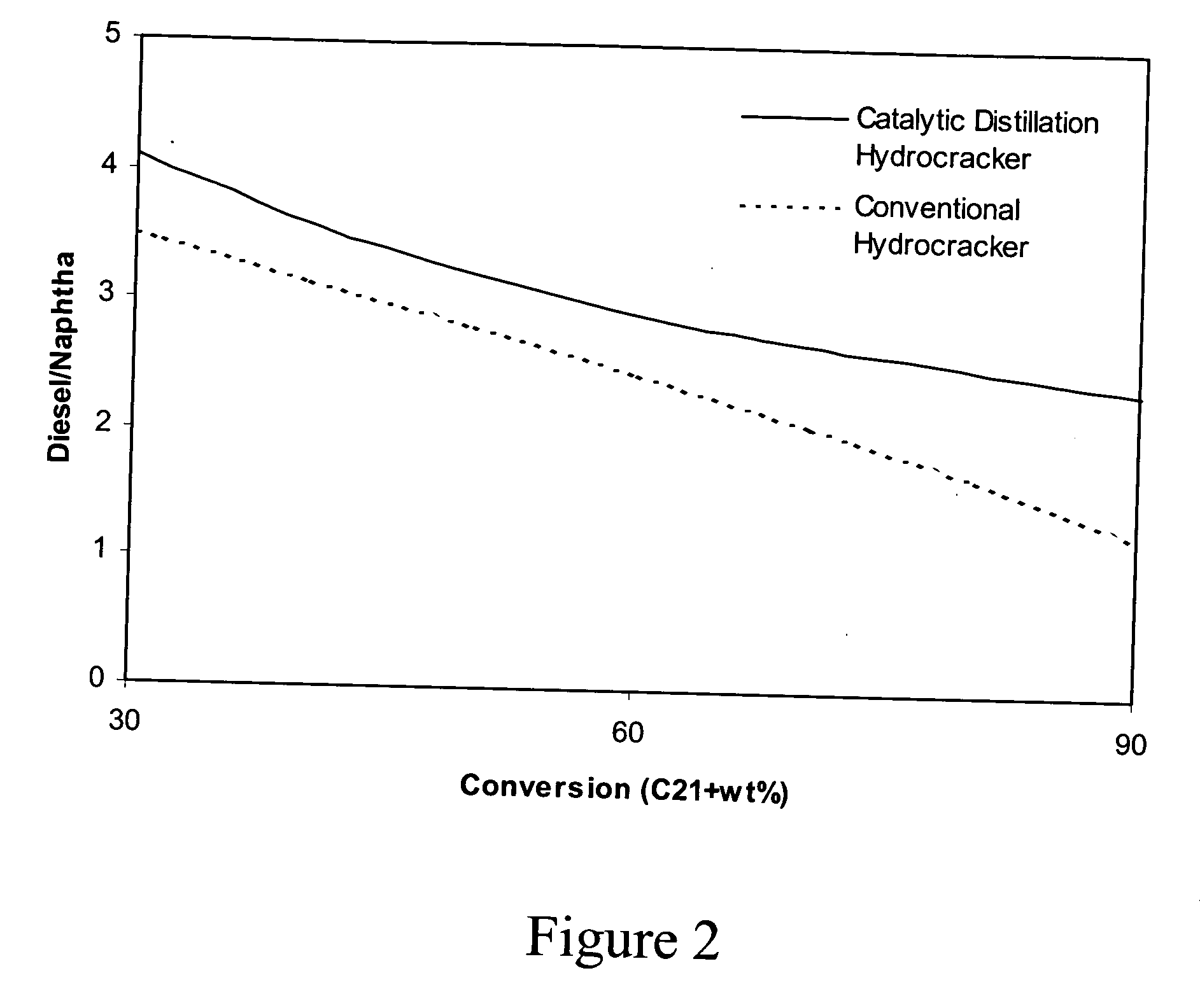

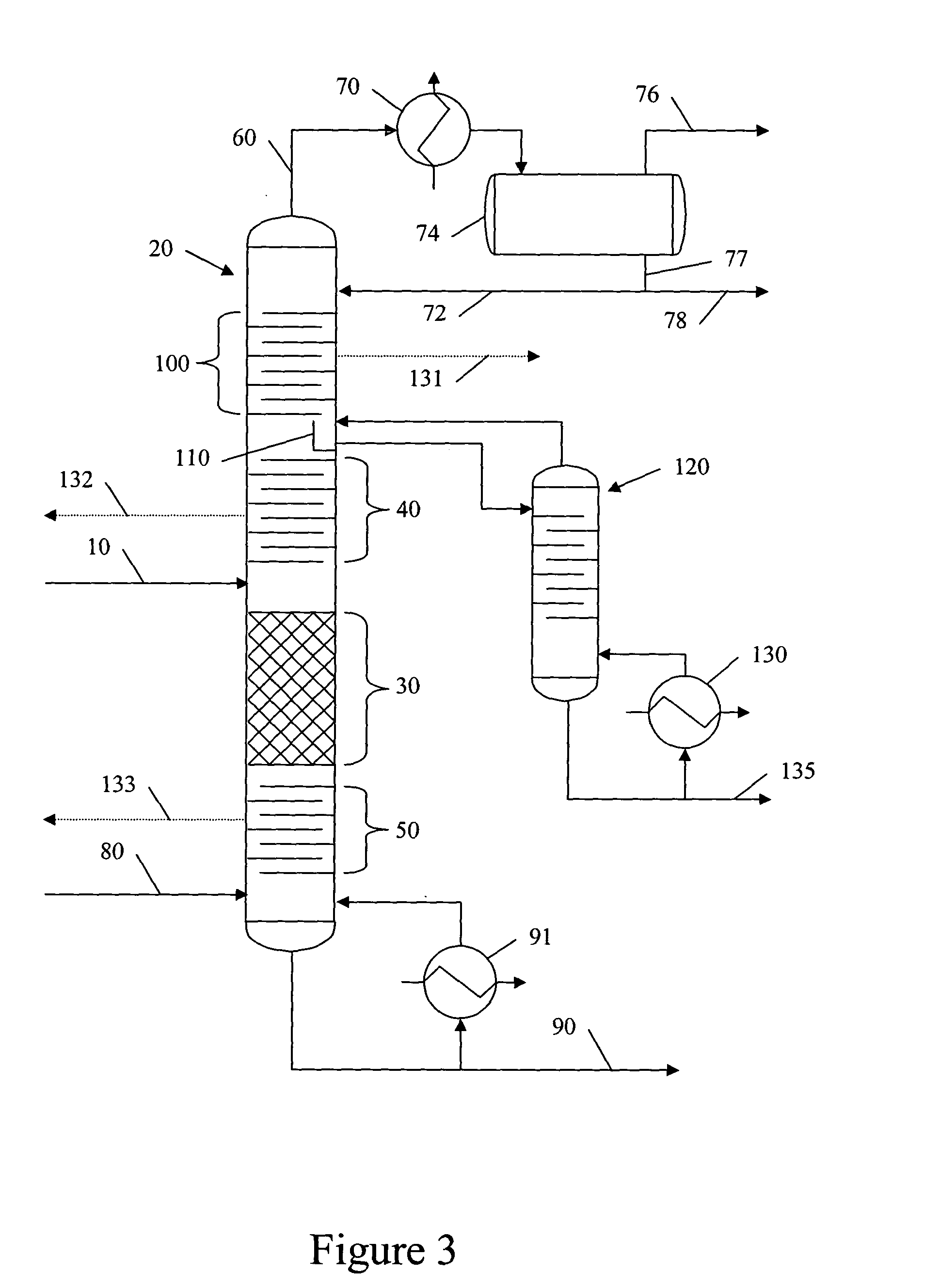

[0018] The present invention describes a method and apparatus for hydroprocessing a hydrocarbon synthesis product. As discussed above, a hydrocarbon synthesis product stream may comprise hydrocarbon molecules that contain from one to eighty, or more, carbon atoms each. These molecules are predominantly straight-chain paraffins. One well known hydrocarbon synthesis process is the Fischer-Tropsch process. Generally, low-temperature Fischer-Tropsch products contain some olefins, and oxygenates, but paraffins are by far the major component. In addition, Fischer-Tropsch products generally do not contain substantial amounts of metals, and sulfur-containing and nitrogen-containing compounds. In this regard, Fischer-Tropsch products differ substantially from conventional crude oil refinery feedstocks for hydrocrackers, which generally contain large amounts of aromatics and naphthenes. In particular, hydrocarbon synthesis products generated by a low-temperature Fischer-Tropsch synthesis are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| outlet temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com