Cleaning composition and apparatus for removing biofilm and debris from lines and tubing and method therefor

a technology of biofilm and debris removal and cleaning composition, which is applied in the direction of cleaning using liquids, detergent compounding agents, dental surgery, etc., can solve the problems of human infection potential, high danger of infection, and difficult to remove biofilms from tubing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

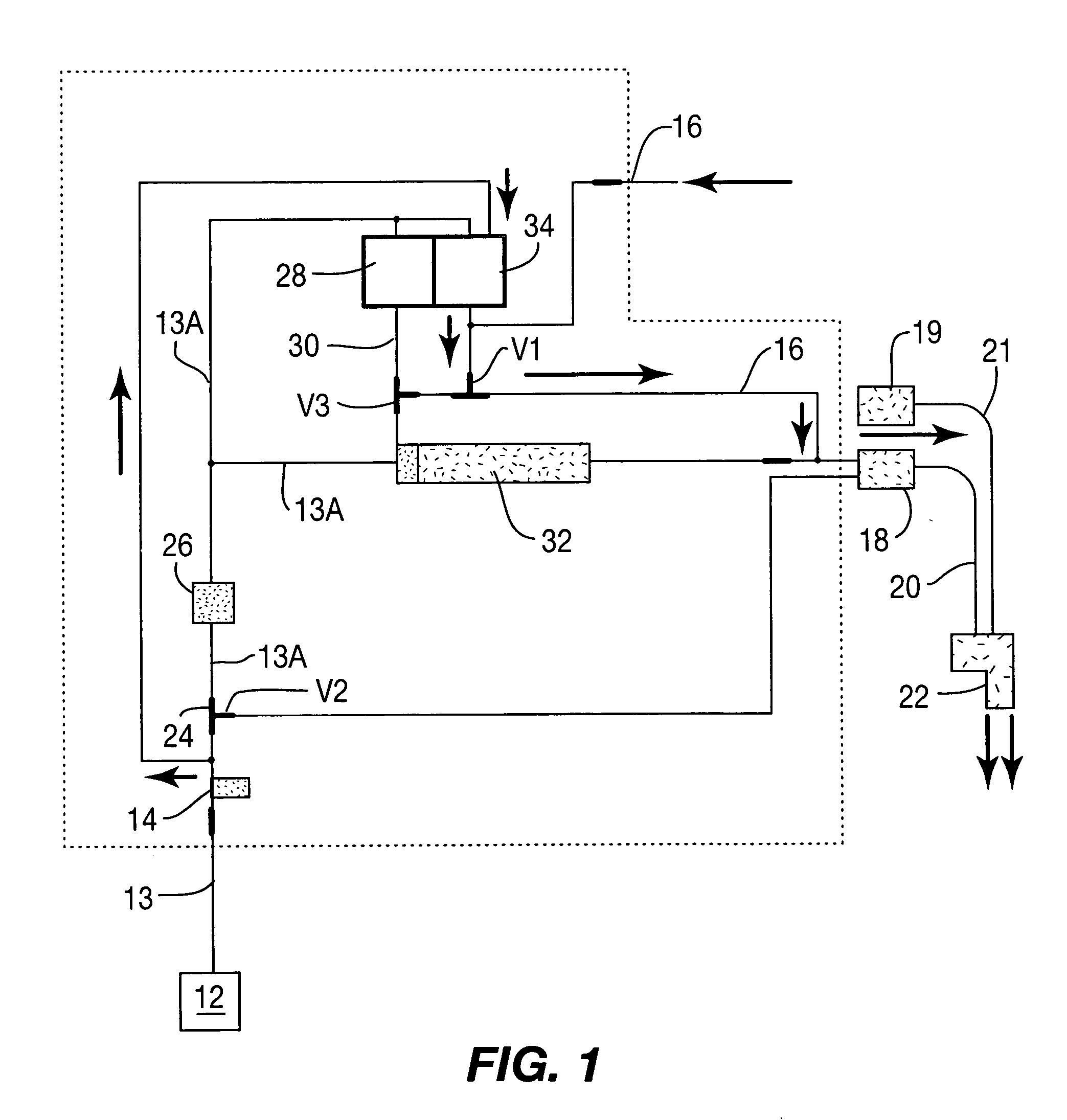

[0068] A portion of dental tubing having a biofilm about one year old on its interior surface is shown in FIG. 2. The biofilm completely covers the interior surface of the tubing and consists of about 200,000 colonies / cm of bacteria.

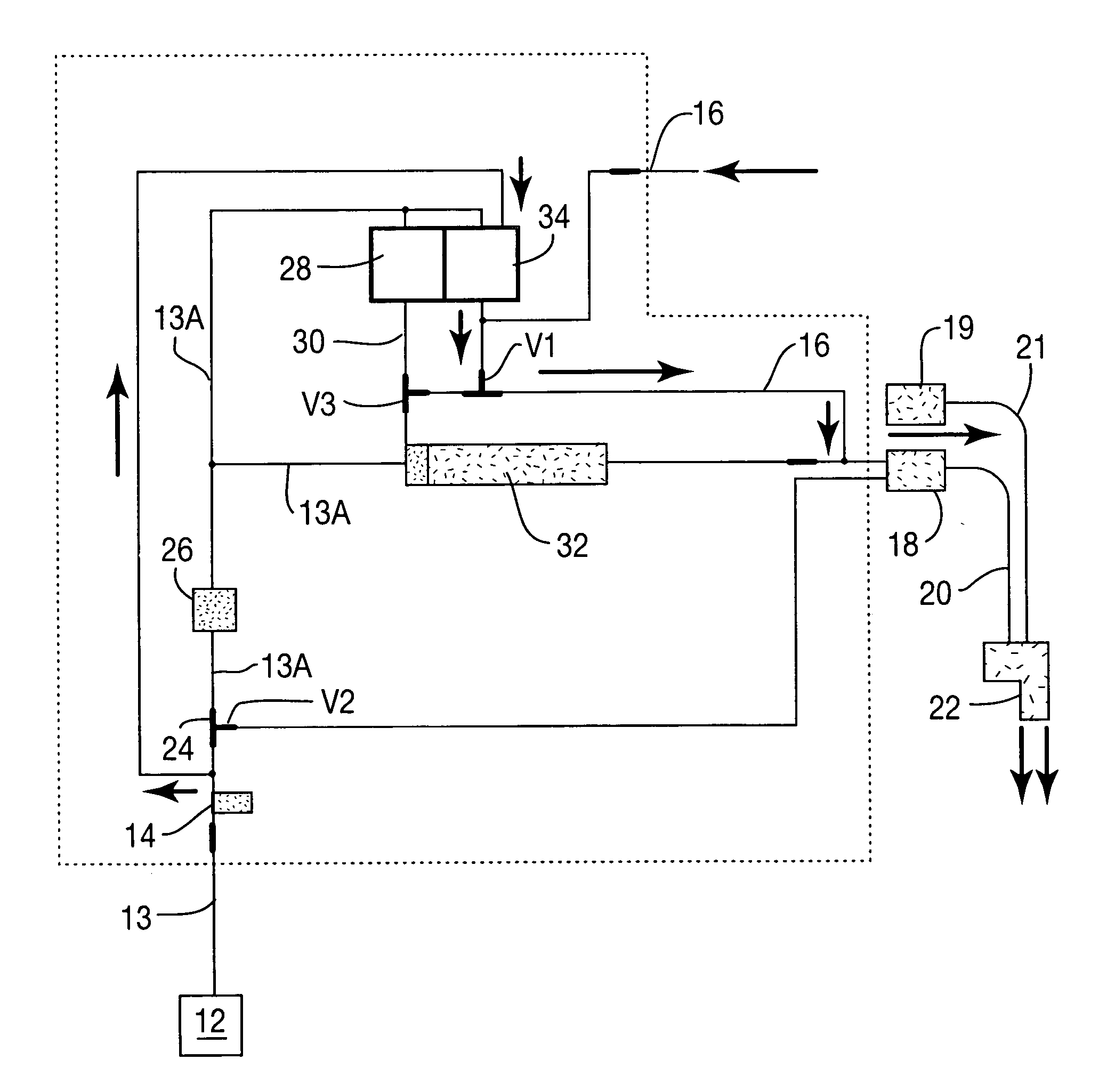

[0069] A three foot section of the tubing was treated in accordance with the invention using a cleaning solution of 3% aqueous hydrogen peroxide containing 5% by weight of inert particles of calcium carbonate 50-100 microns in size, and surfactants including about 2% of an anionic surfactant, sodium dodecyl sulfate, and about 1% of a nonionic surfactant. The cleaning solution was added to the mixing chamber 28 of FIG. 1 and air was added to the mixing chamber from a 1 HP air compressor regulated at 30-60 psi, the air being continuously pulsed. The amount of air and the pulse rate were regulated to optimize mixing of the ingredients and the turbulence generated inside the tubing. The mixture was passed to the dental tubing to permit turbulent cleaning of...

example 2

[0073] A cleaning solution was made by mixing 50 grams of calcium carbonate particles having a particle size of 10-100 microns into 450 ml of a solution containing 3% by weight of hydrogen peroxide solution, 2% by weight of a surfactant, sodium dodecyl sulfate and 1% of a nonionic surfactant.

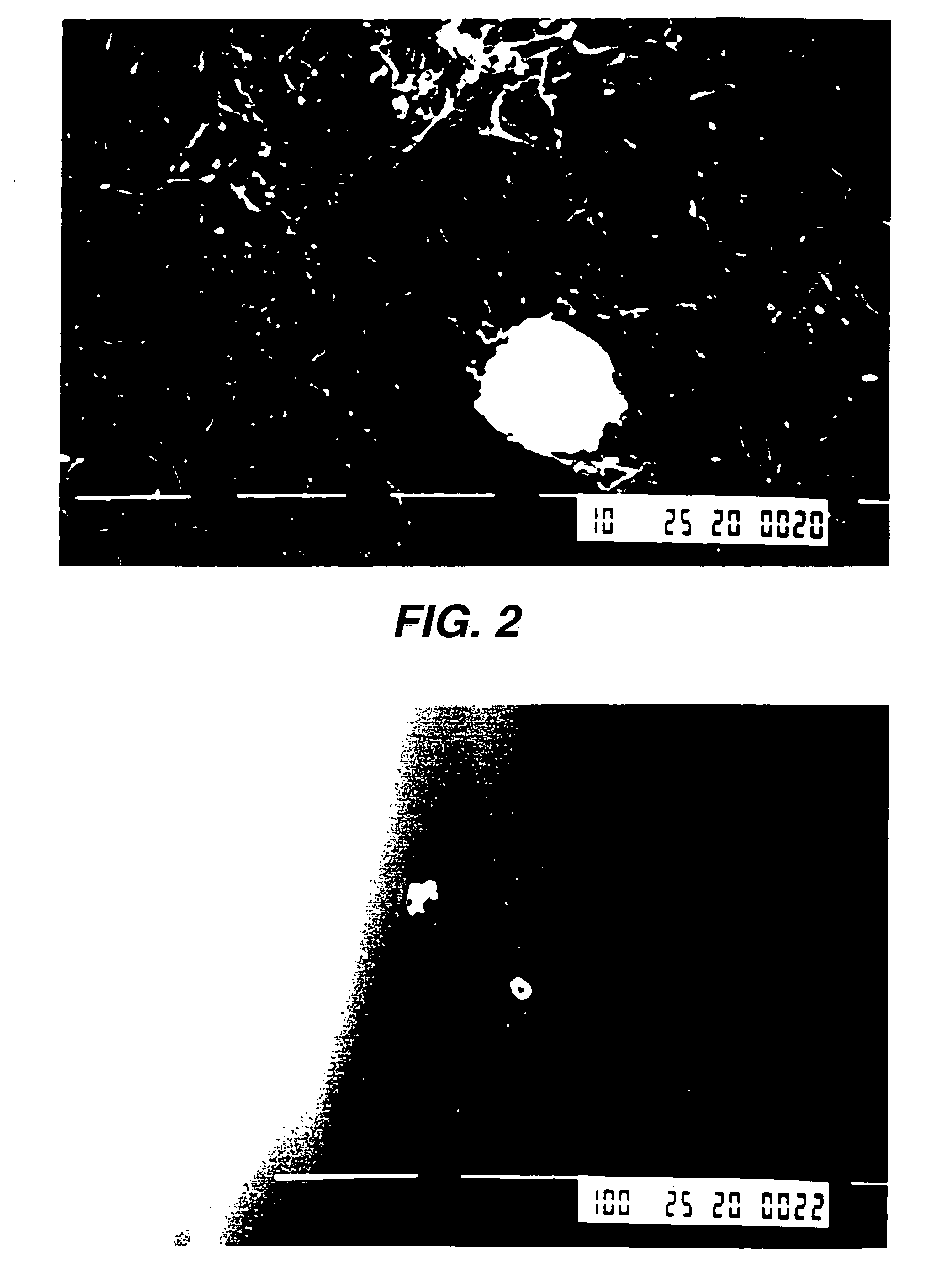

[0074] The above mixture was introduced into a used dental tubing 3 feet long and 1.8 mm in diameter having a biofilm thereon, as shown in FIG. 4, together with air supplied by a compressor set between 30 and 60 psi. The cleaning composition was flushed through the tubing for about 3 minutes.

[0075] The tubing was then flushed with 200 ml of distilled water.

[0076] The number of bacterial colonies in the tubing decreased from an initial value of 7.15×105 per linear cm of tubing down to zero after cleaning. The CFU / ml of water flowing in the tube was reduced from an initial value of 3.19×106 to zero after cleaning.

[0077] The SEM photograph of FIG. 5 is an overall view of the interior wall of th...

example 3

[0078] 576 Milliliters of 3% by weight of aqueous hydrogen peroxide solution was admixed with 2% by weight of sodium dodecyl sulfate surfactant. The cleaning reagent was introduced into used dental tubing with air supplied by a compressor set at a pressure of 30 to 60 psi. After treatment for three minutes, the tubing was flushed with 200 ml of water.

[0079] The number of bacterial colonies per cm of tubing after culture decreased from an initial value of 1×105 to zero. The CFU / ml of the water decreased from an initial value of 3.01×106 to zero.

[0080]FIG. 6 is a photograph of the interior wall of the tubing prior to treatment. FIG. 7 is a photograph of the interior wall of the tubing after treatment.

[0081] Thus in the presence of hydrogen peroxide, surfactant and air under a preselected pressure, complete cleaning was achieved even in the absence of solid particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com