Fire log made of recycled materials and a method and an apparatus for manufacturing the same

a technology of fire logs and recycled materials, which is applied in the direction of biofuels, firelighters, solid fuels, etc., can solve the problems of large quantities of particulate matter and carbon oxides in fire logs, emissions that could contain carcinogens, and first cause of pollution of moisture content in fire logs, so as to increase the oil-absorption capacity of solid fuel blocks, the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

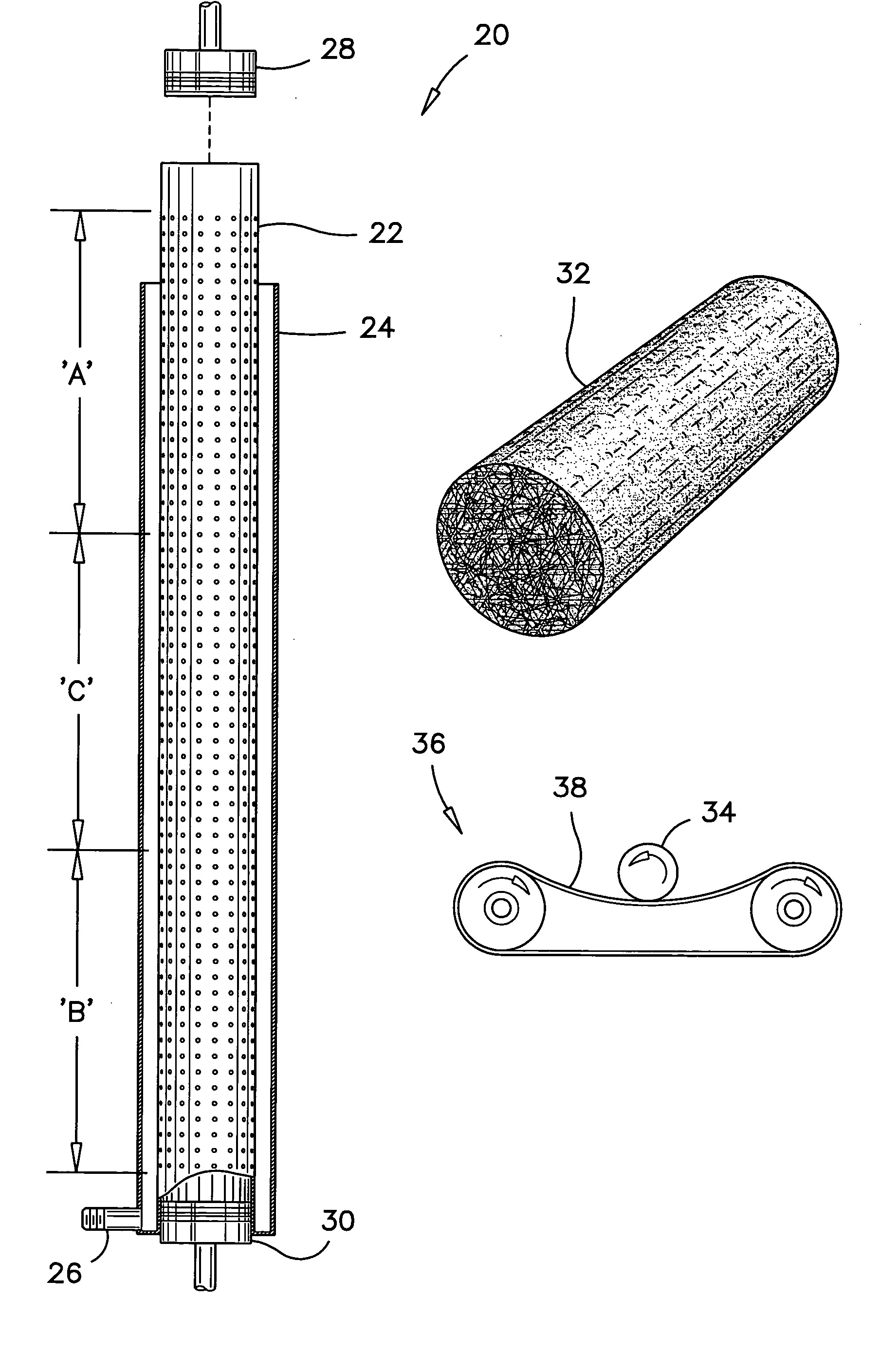

[0028] While this invention is susceptible of embodiment in many different forms, there is shown in the drawings and will be described in details herein one specific embodiment, with the understanding that the present disclosure is to be considered as an example of the principles of the invention and is not intended to limit the invention to the embodiment illustrated and described.

[0029] The fire log according to the preferred embodiment of the present invention is made of organic fibers obtained from waste paper and card board, impregnated with used vegetable oil and encased in vegetable wax. The vegetable oil is the primary fuel element and is comprised in the final product in a proportion of about 65%-75% by weight. The waste paper is the secondary fuel element and is comprised in the final product in a proportion of about 20%-30% by weight. The vegetable wax is athird fuel element and is used as a casing to prevent the leakage of the vegetable oil from the fibrous base. Its co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| calorific value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com