Fluid filled vibration damping device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

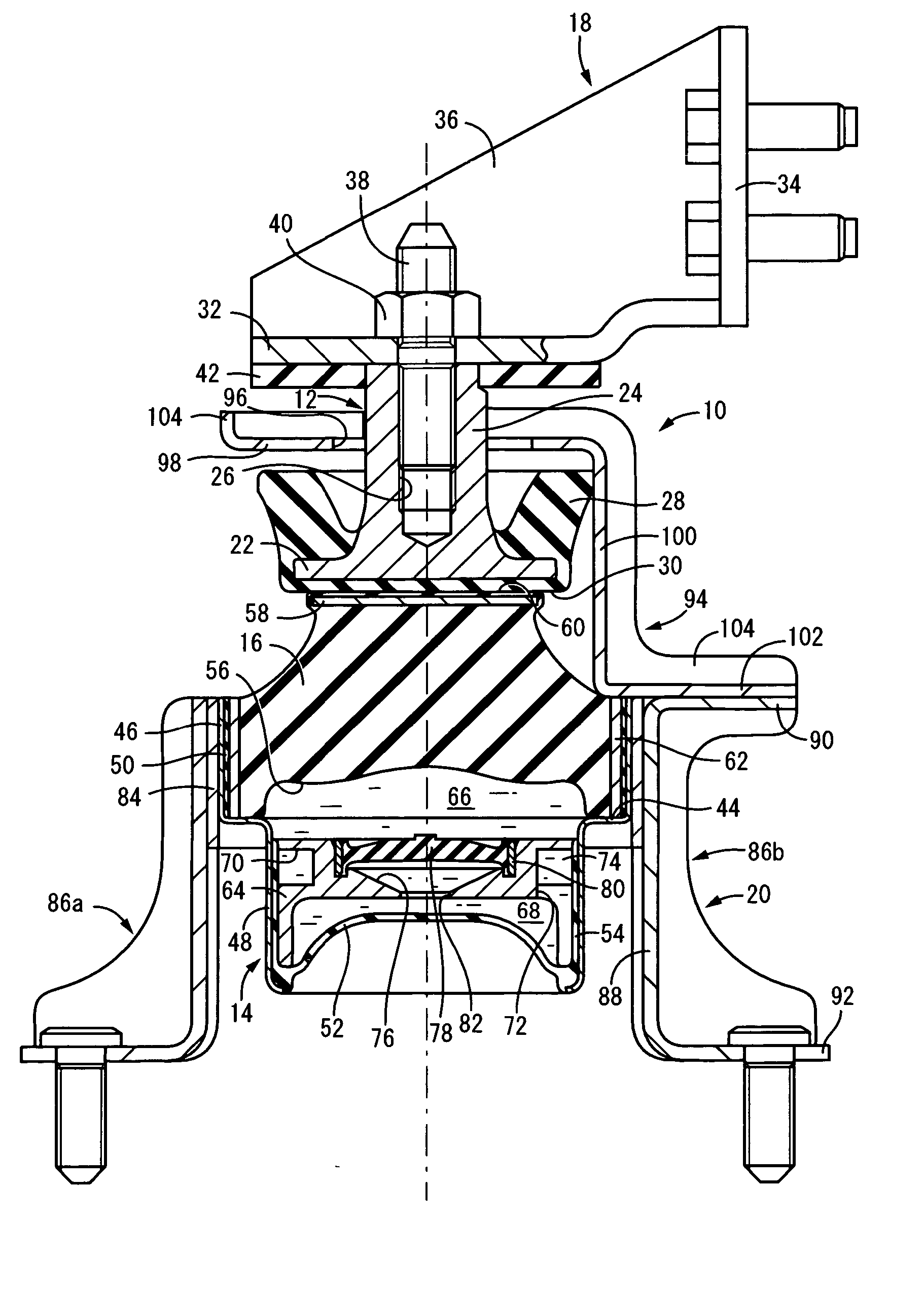

[0031] Referring first to FIG. 1, there is shown a fluid-filled vibration-damping device in the form of an engine mount 10 for automotive vehicles, which is constructed according to the invention. The engine mount 10 has a structure comprising a rubber elastic body 16 disposed between a metallic first mounting member 12 fixable to a power unit (not shown), and a metallic second mounting member 14 fixable to a body of the vehicle (not shown). The first mounting member 12 is fixed via a power unit-side bracket 18 to the power unit, while the second mounting member 14 is fixed via a body-side bracket 20 to the body, so that the power unit is mounted on the body in vibration-damping fashion. With the engine mount 10 of this embodiment installed in this state, the engine mount 10 bears a distributed support load of the power unit or static load exerted thereon in the generally vertical direction in FIG. 1, and exhibits effective damping action against vibration applied thereto in the gen...

third embodiment

[0068] FIGS. 5 and 6 illustrates a fluid-filled vibration-damping device in the form of an automotive engine mount 120 of construction according to the invention. This engine mount 120 has a construction in which a rubber elastic body 126 is disposed between a metallic first mounting member 122 fixable to the power unit, and a metallic second mounting member 124 fixable to the body. The first mounting member 122 is fixed to the power unit, while the second mounting member 124 is fixed to the body, so that the power unit is superimposed on the body in a vibration-damping manner. With the engine mount 120 of this embodiment installed as stated above, power unit distributed support load is input in the generally vertical direction in FIGS. 5 and 6, and the engine mount 120 exhibits excellent vibration damping effect with respect to input vibration in the generally vertical direction in FIGS. 5 and 6.

[0069] Described in detail, the first mounting member 122 has an overall long plate con...

fourth embodiment

[0094] Namely, FIGS. 7 and 8 shows an engine mount 202 of construction according to the invention. This engine mount 202 comprises: a metallic inner sleeve 204 constituting a first mounting member; a metallic outer sleeve 206 constituting a second mounting member; and a rubber elastic body 208 interposed between the inner and outer sleeves 204, 206. The inner sleeve 204 is attached to the body side, while the outer sleeve 206 is attached to the power unit side. In FIGS. 7 and 8, the inner sleeve 204 and outer sleeve 206 are shown positioned generally concentrically, with the distributed support load of the power unit acting in the vertical direction in the drawing.

[0095] Described more specifically, the inner sleeve 204 has a thick-walled, small-diameter cylindrical shape, to the outer circumferential surface of which is bonded a cushion rubber 210 as a rebound stop rubber projecting outward in the axis-perpendicular direction, through vulcanization of a rubber material for forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com