Combustion-based emission reduction method and system

a technology of emission reduction and combustion, applied in combustion control, combustion types, lighting and heating apparatuses, etc., can solve the problems of increasing the formation of no.sub.x, co, solid fuel combustors, and invariably unbalanced primary fuel distribution of furnaces with multiple primary fuel inputs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

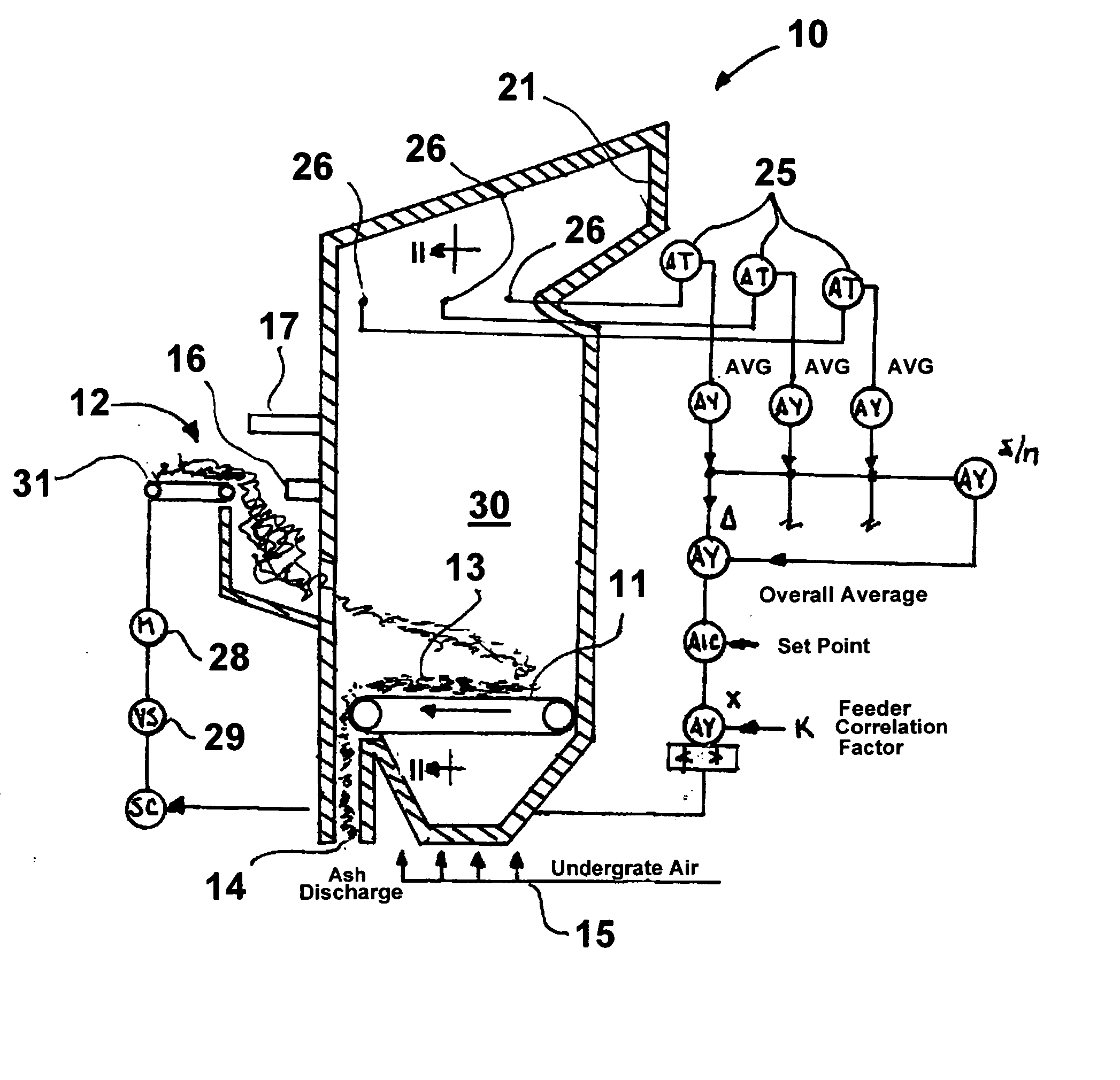

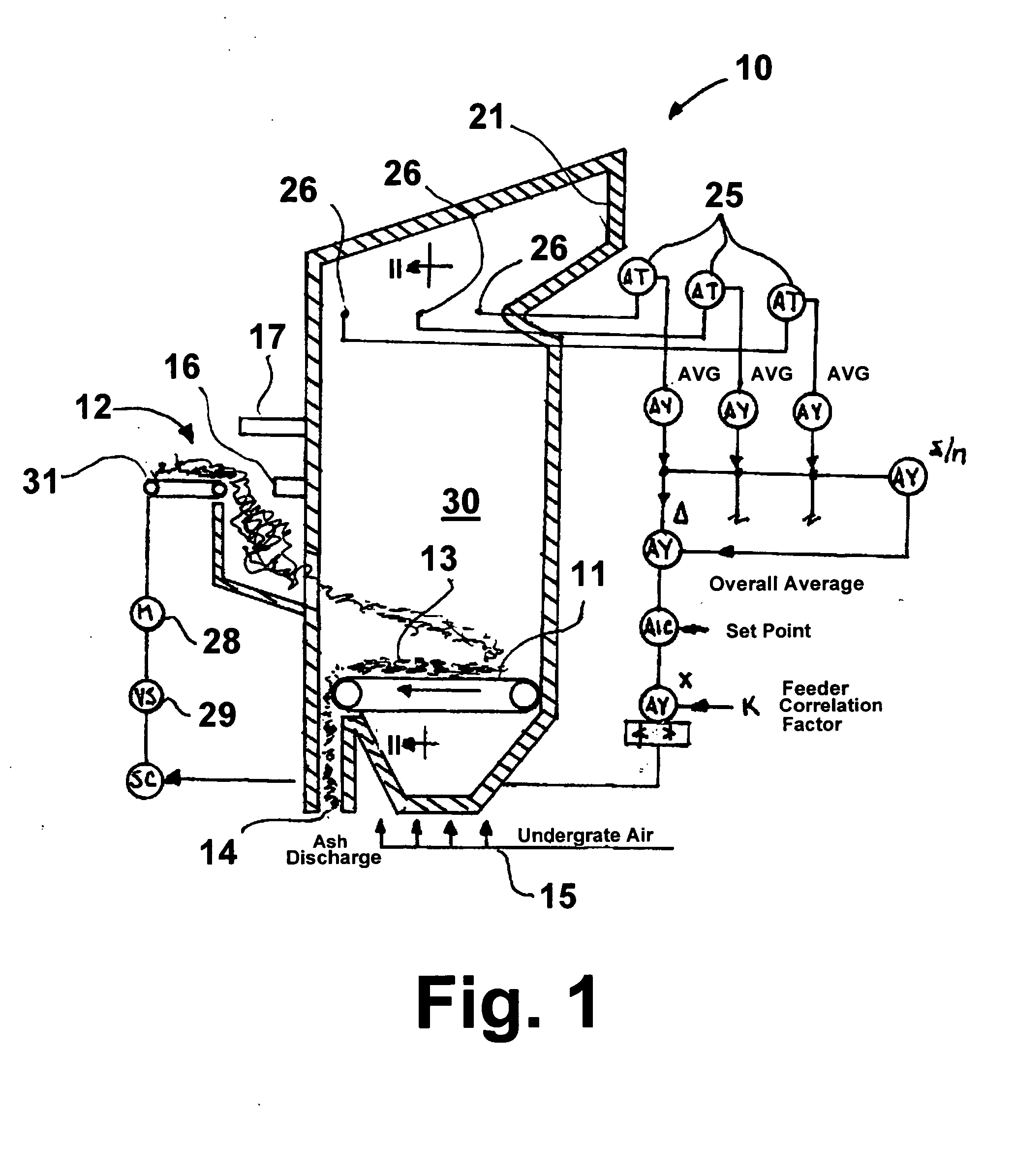

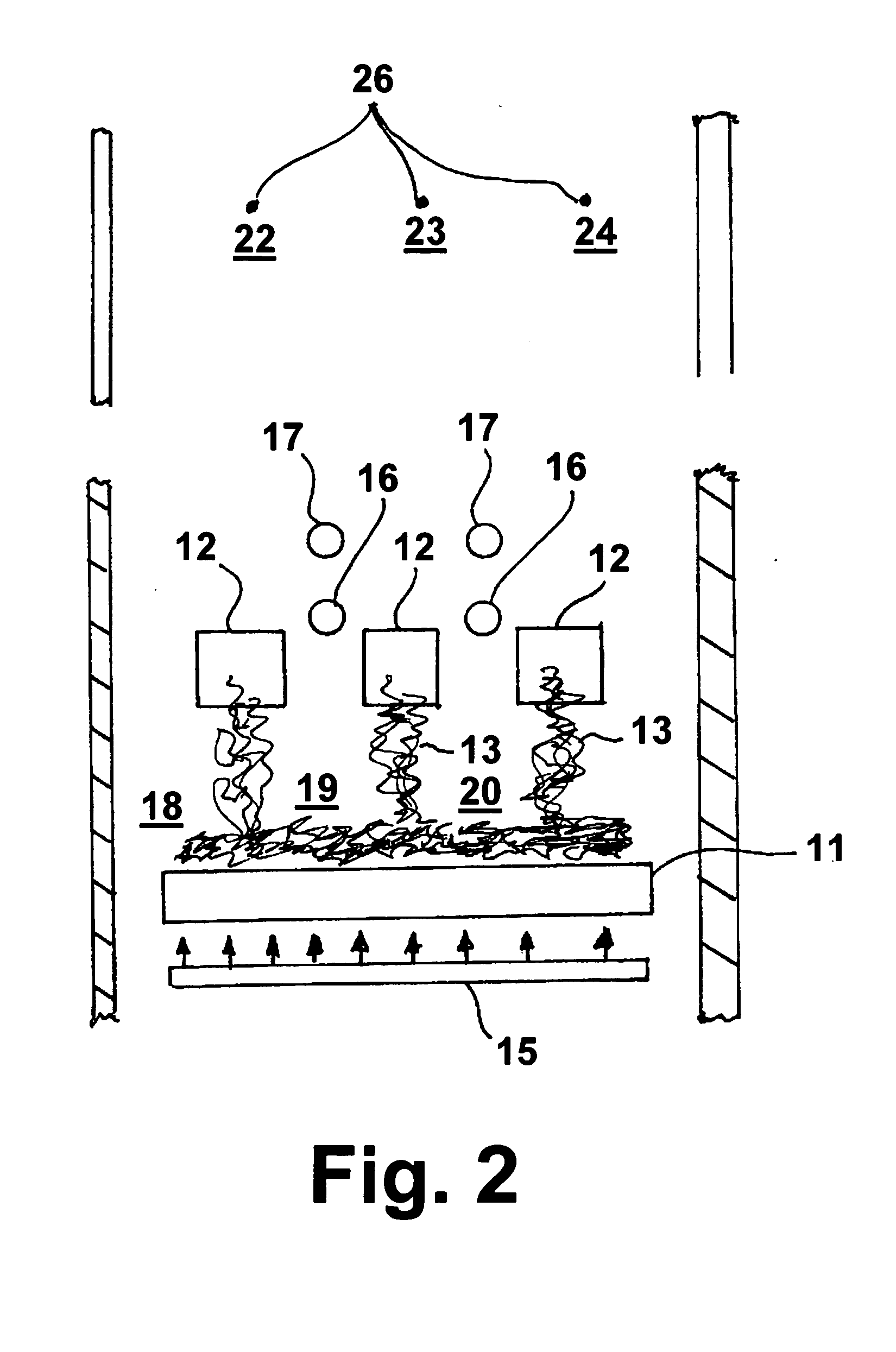

[0021] The invention claimed herein is a method and system for combustion-based emissions reduction from spreader-stokers, grate fired combustors and furnaces all of which employ multiple primary fuel input means. In the case of stokers, the primary fuel input means are in the form of multiple feeders. Other furnaces or combustors to which the method and system of this invention may be applied are furnaces and combustors having multiple solid-, liquid- and / or gaseous-fired primary fuel burners. Although described in the context of a grate-fired stoker, the method and system of this invention are applicable to any furnace system employing multiple primary fuel inputs and no intention to limit the scope of this invention to grate-fired stokers should be inferred.

[0022] FIGS. 1 and 2 show a grate-fired spreader stoker comprising a combustion-based emissions reduction system in accordance with one embodiment of this invention. Stoker 10 comprises a stoker grate 11 disposed in the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com