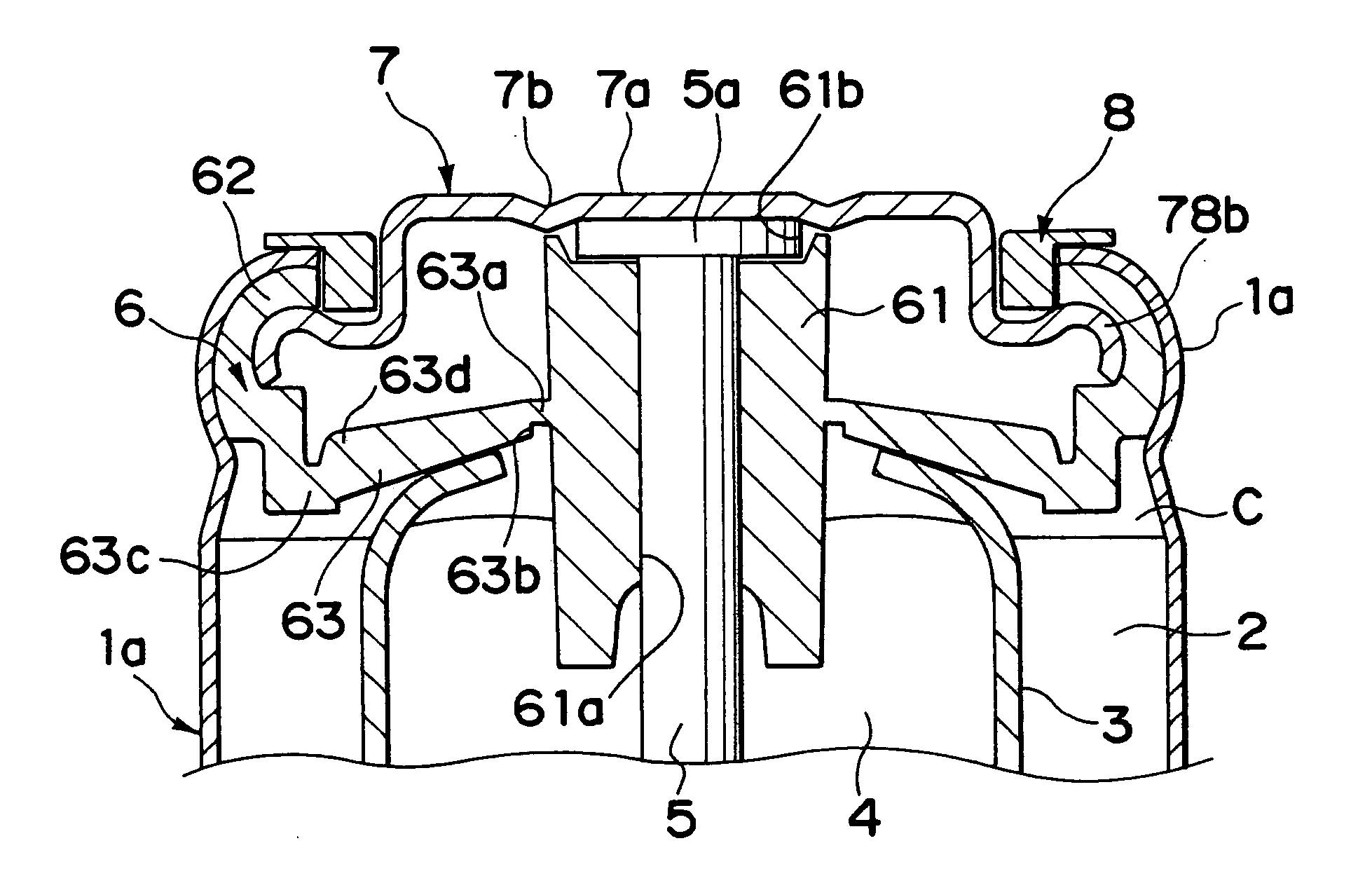

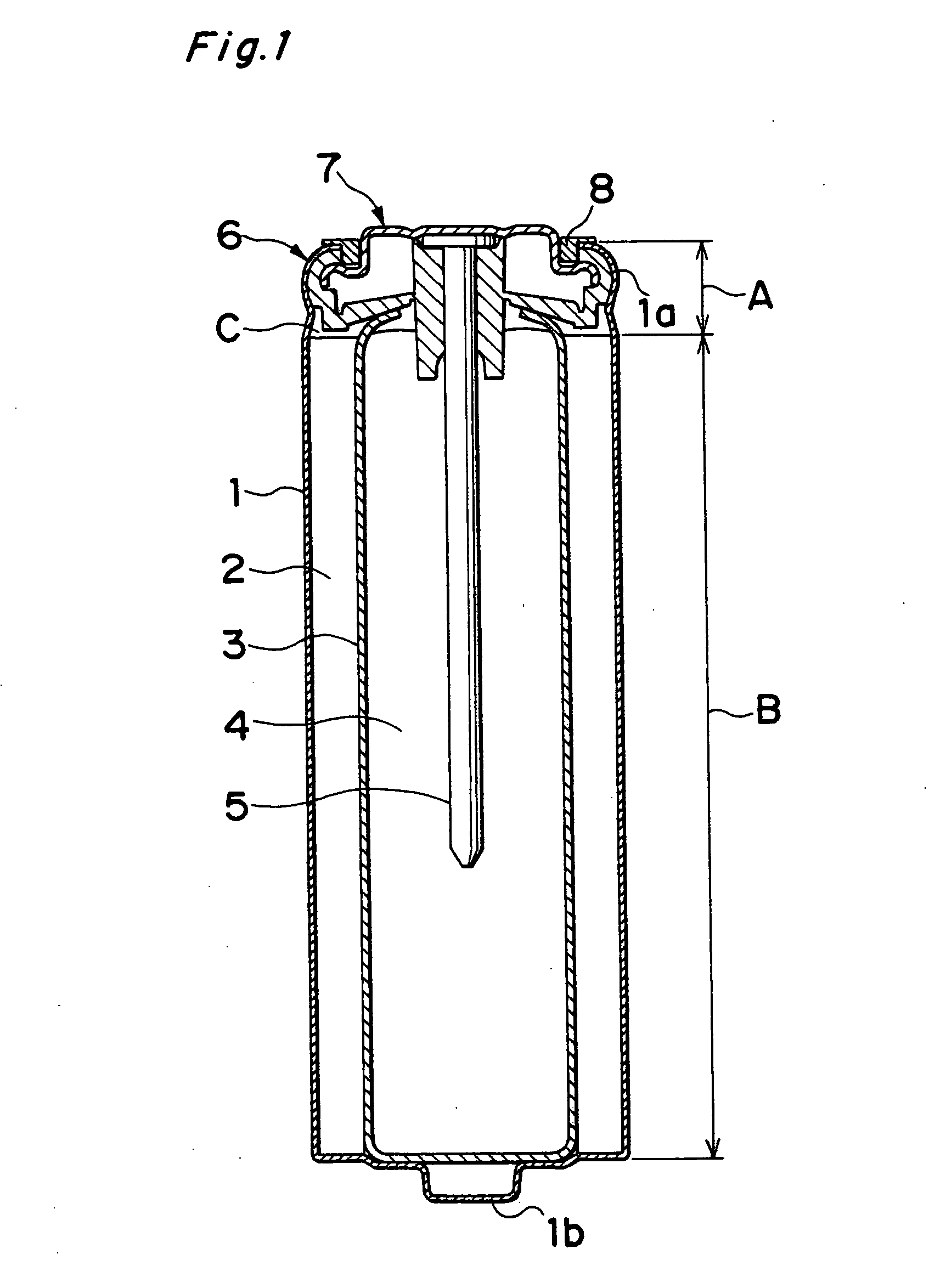

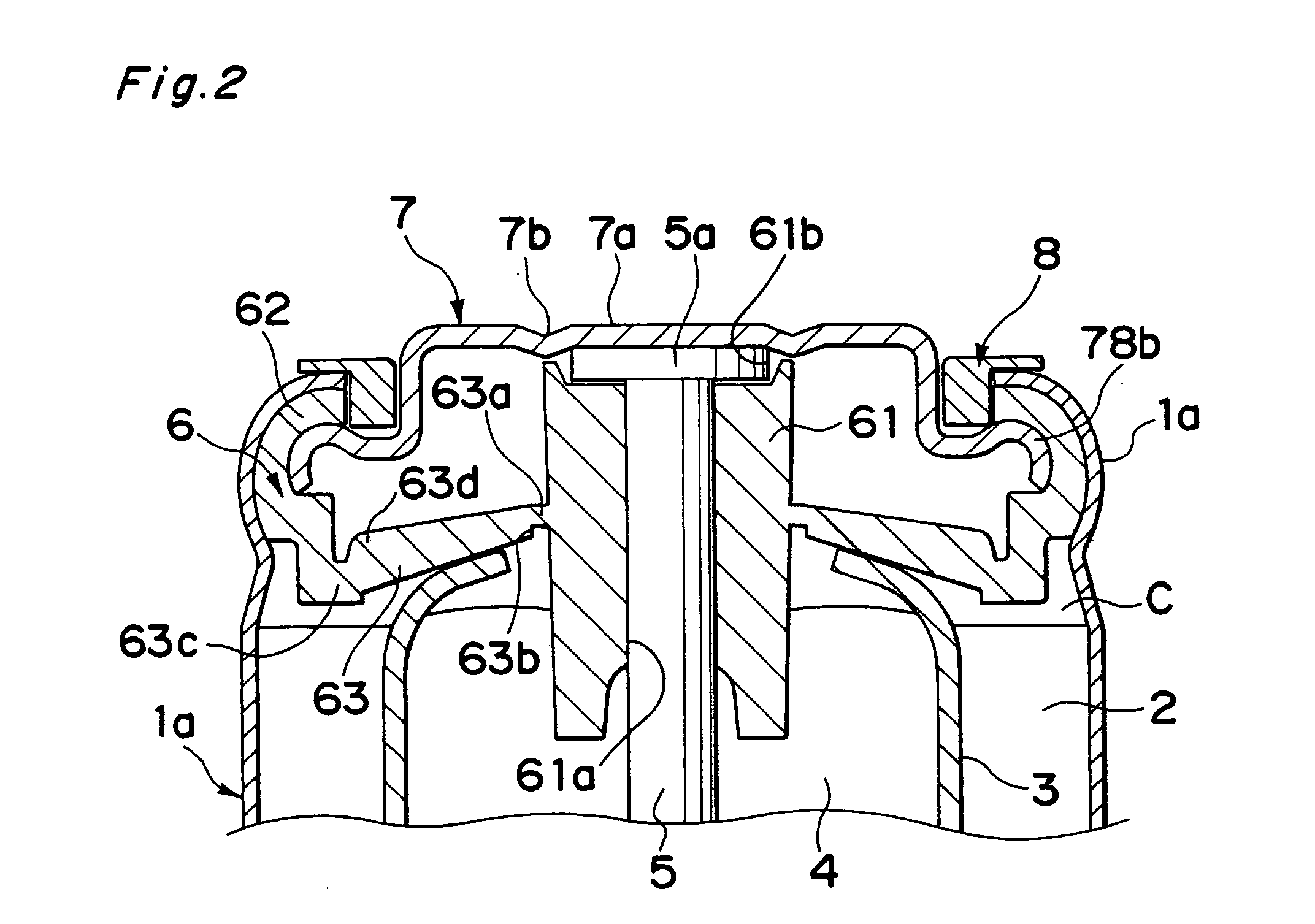

Alkaline dry cell

a dry cell and alkaline technology, applied in dry cells, cell components, electrical equipment, etc., can solve the problems of internal electrolyte solution leakage from the sealing portion, difficult machining process, external can tend to be deformed, etc., to increase the actual increase the inner capacity of the battery, and increase the discharging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 5

[0133] Next, a cathode material (11.0 g), prepared by mixing manganese dioxide, graphite and water at a ratio of 92:5:3 (weight ratio) through an electrolytic method, was processed and molded into a cathode having a cylindrical shape measuring 9.1 mm in inner diameter, 13.3 mm in outer diameter and 43.0 mm in height, and this was inserted into an external can for a size "AA" alkaline dry cell. Thereafter, a groove was formed at a position 3.7 mm apart from the opening edge of the external can in the height direction. This arrangement is made so that when the sealing member is inserted later, the sealing member is held at the position of the groove so as not to be shoved deeper than the groove position. Moreover, inside the external can, pitch is applied from the opening edge to the position 3.7 mm in depth in the height direction so as to improve the adhering property between the external can and the sealing member.

[0134] Next, non-woven cloths, each made of vinylon and rayon having...

example 6

[0137] A size "AA" alkaline dry cell is formed in the same manner as Example 5 except that the average curvature radius of the curved portion on the outer circumferential portion of the metal plate (anode terminal plate) is set to 0.8 mm.

example 7

[0138] A size "AA" alkaline dry cell is formed in the same manner as Example 5 except that the average curvature radius of the curved portion on the outer circumferential portion of the metal plate (anode terminal plate) is set to 1.0 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| curvature radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com