Fusers and intermediate transfer members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

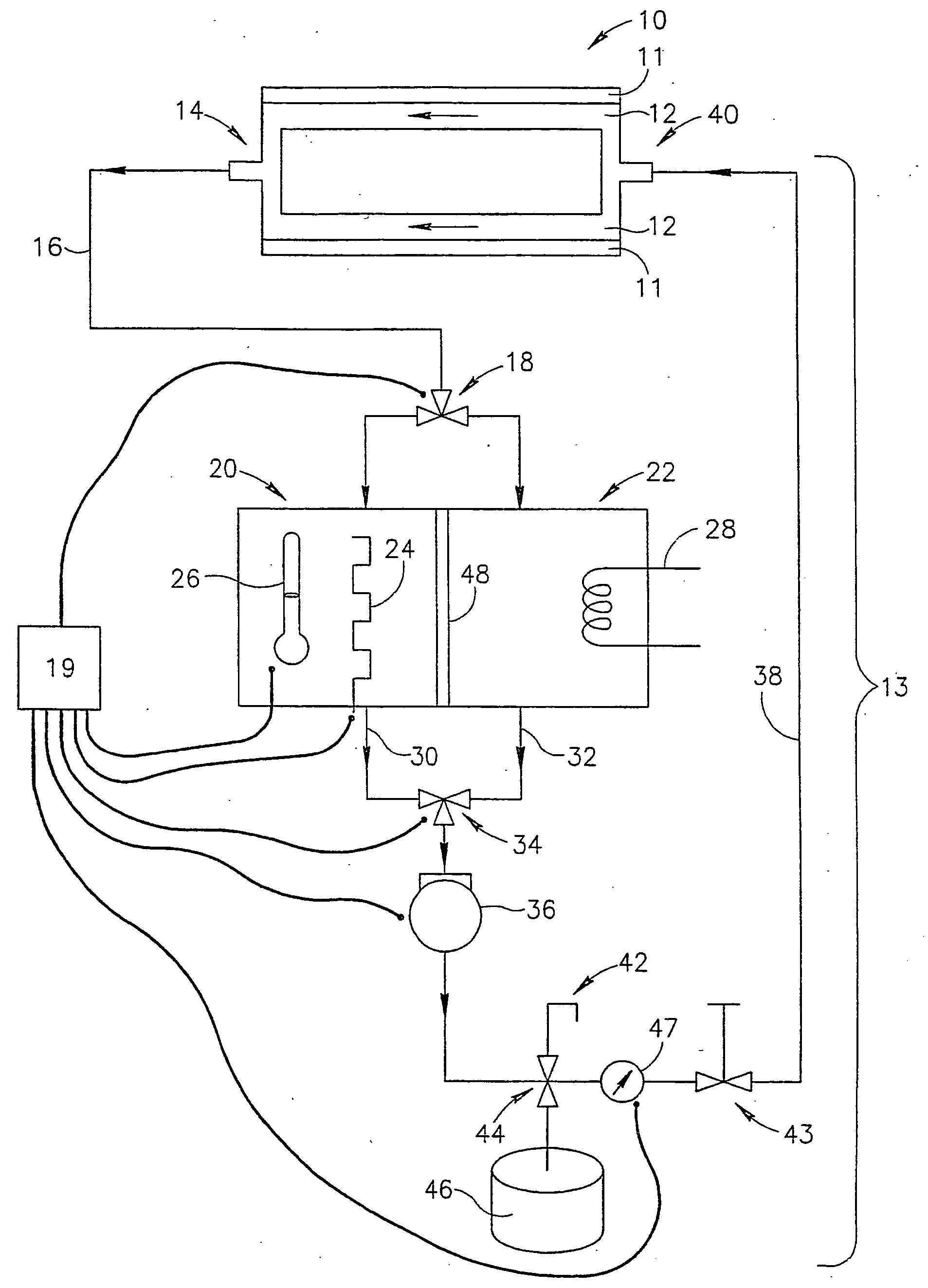

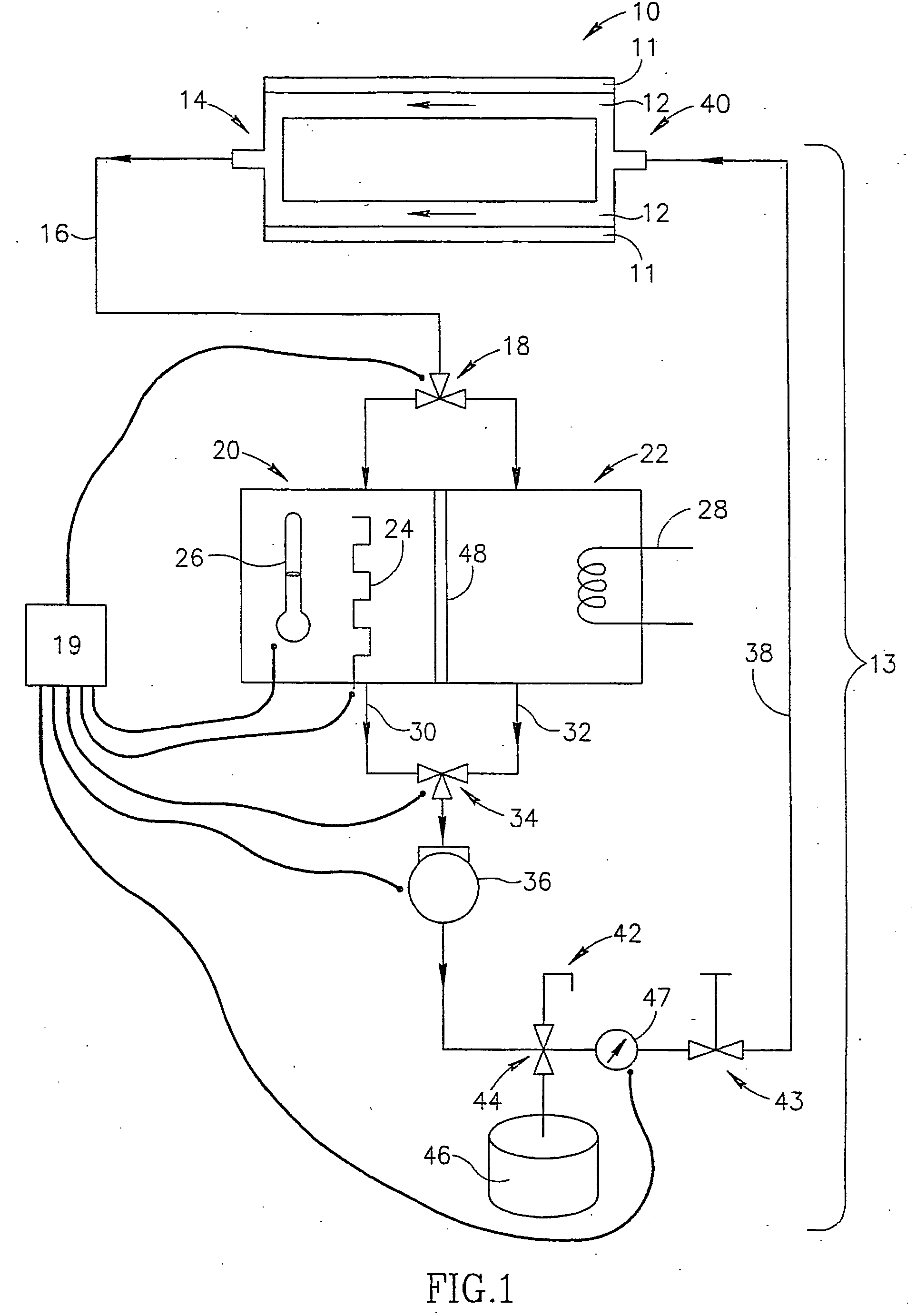

[0053] The embodiment shown in FIG. 1 has a drum 10, with a region 12 filled with a liquid. Optionally, there is a thin outer region 11, between region 12 and the outer surface of drum 10, which contains its own liquid, optionally a different liquid more volatile than the liquid in region 12, which maintains gas pressure supporting the outer surface when the drum is hot. Generally, the liquid in region 12 need not be replaced when the temperature of the drum is to be changed. Region 12 is connected to a liquid transfer system 13, consisting of pipes, connectors, valves, and reservoirs. An outlet 14 of region 12 connects region 12 to a return pipe 16. In those embodiments where there is an outer region 11 between region 12 and the outer surface of drum 10, region 12 optionally remains fixed in place while drum 10 is rotating. In this case, outlet 14 is optionally an ordinary pipe connector. If region 12 rotates with the outer surface of drum 10, then outlet 14 optionally comprises a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com