Wall patch

a wall and patch technology, applied in the field of wall patches, can solve the problems of not being able to achieve satisfactory results all the time, not being able to knead the putty or use the spatula to level the wall face, and not being able to handle the materials for wall repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

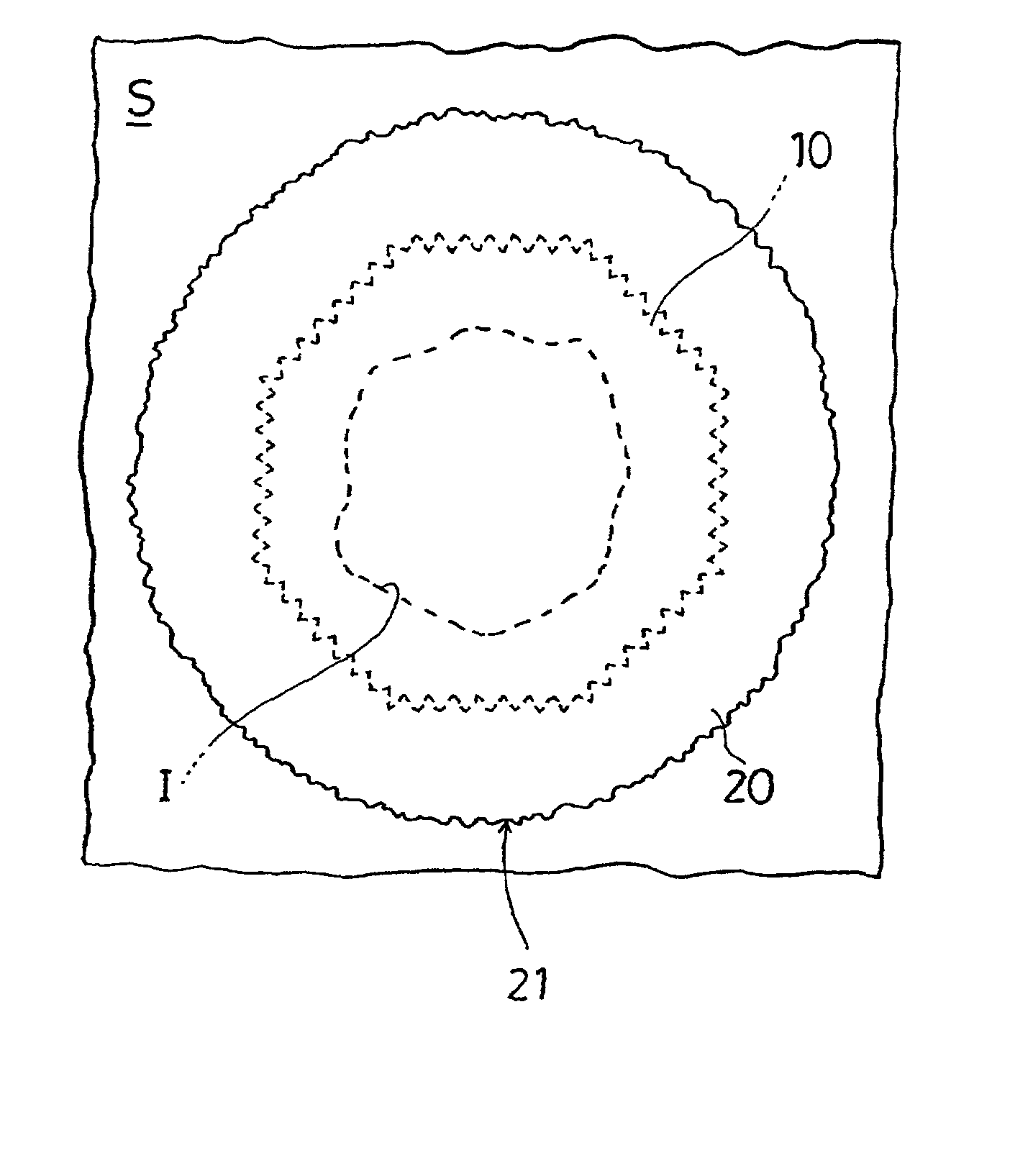

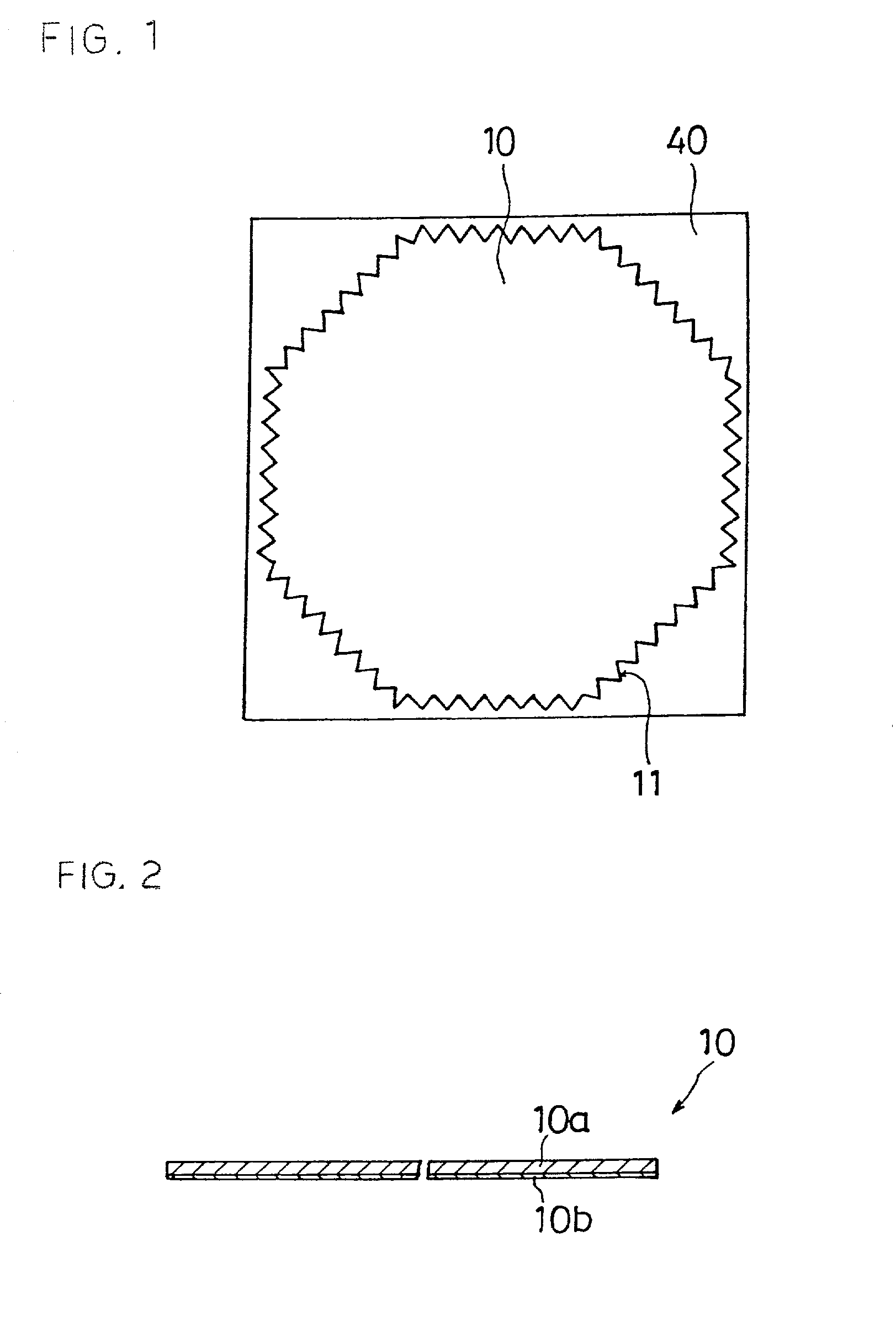

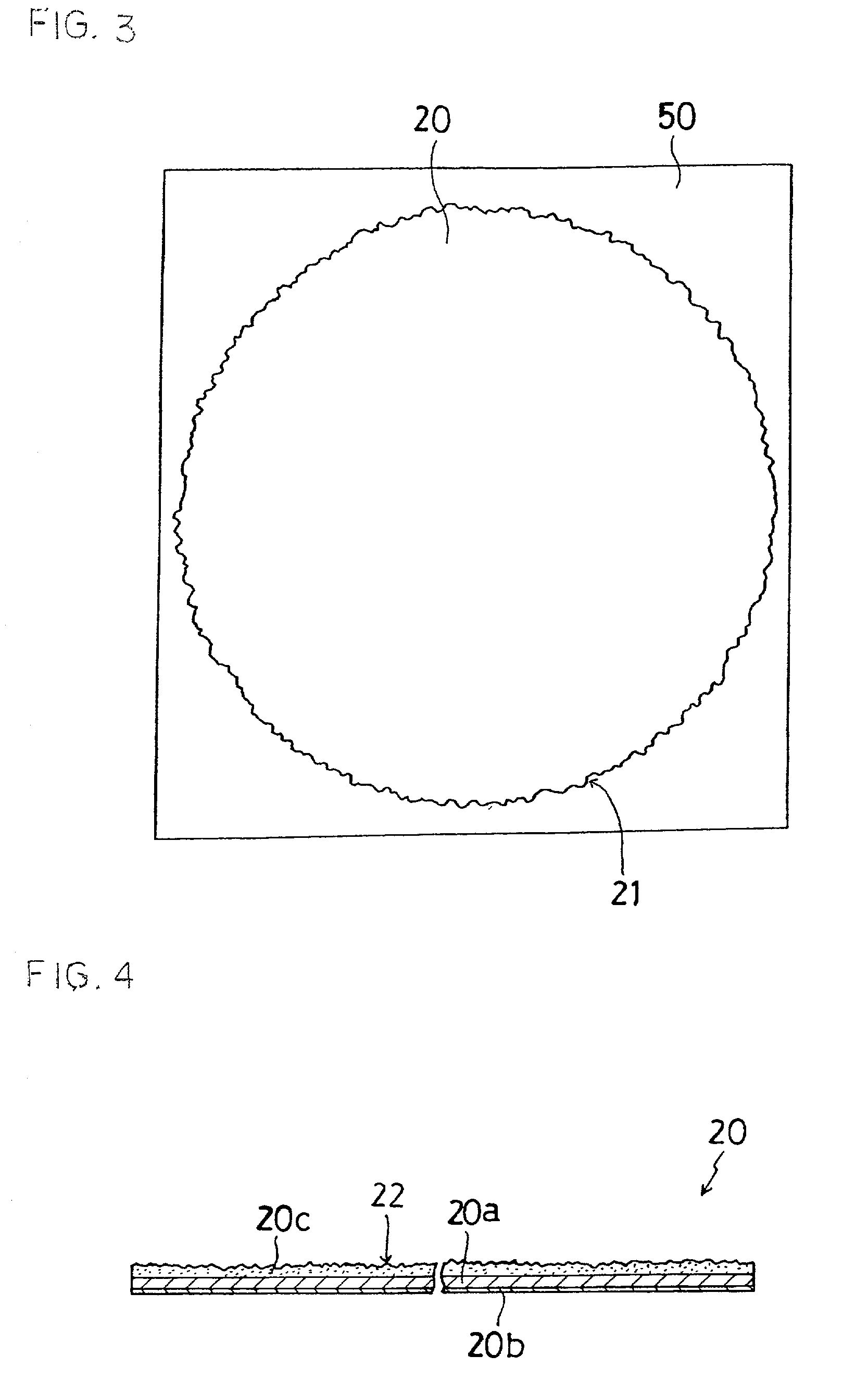

[0036] As shown in FIGS. 1, 2, 6 and 7, a wall patch according to a preferred embodiment of the present invention consists of a lower sheet 10, an upper sheet 20 and a boundary-erasing agent 30.

[0037] The lower sheet 10 can be supplied in a state stuck on a mounting cardboard 40. In use, the lower sheet 10 is peeled off the cardboard 40 and put over a flaw or wound 1, such as a hole or a dent, in a wall S.

[0038] The lower sheet 10 may be circular, polygonal or relatively round, but could alternatively be square or triangular.

[0039] The edge 11 of the lower sheet 10 is notched. The notched edge 11 facilitates the adhesion of the lower sheet 10 to the wall S. With the upper sheet 20 stuck over the lower sheet 10, the notched edge 11 makes the terraced surface of the wall 40 inconspicuous. Alternatively, the edge 11 of the lower sheet 10 might not be notched.

[0040] The lower sheet 10 is a reinforcement sheet directly stuck to the wall S to cover up the flaw I such as a hole or a dent i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com