Case for Archery Equipment

a technology for archery equipment and cases, applied in the field of cases for archery equipment, can solve the problems of large equipment, large equipment, and relatively delicate equipment, and achieve the effect of non-deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

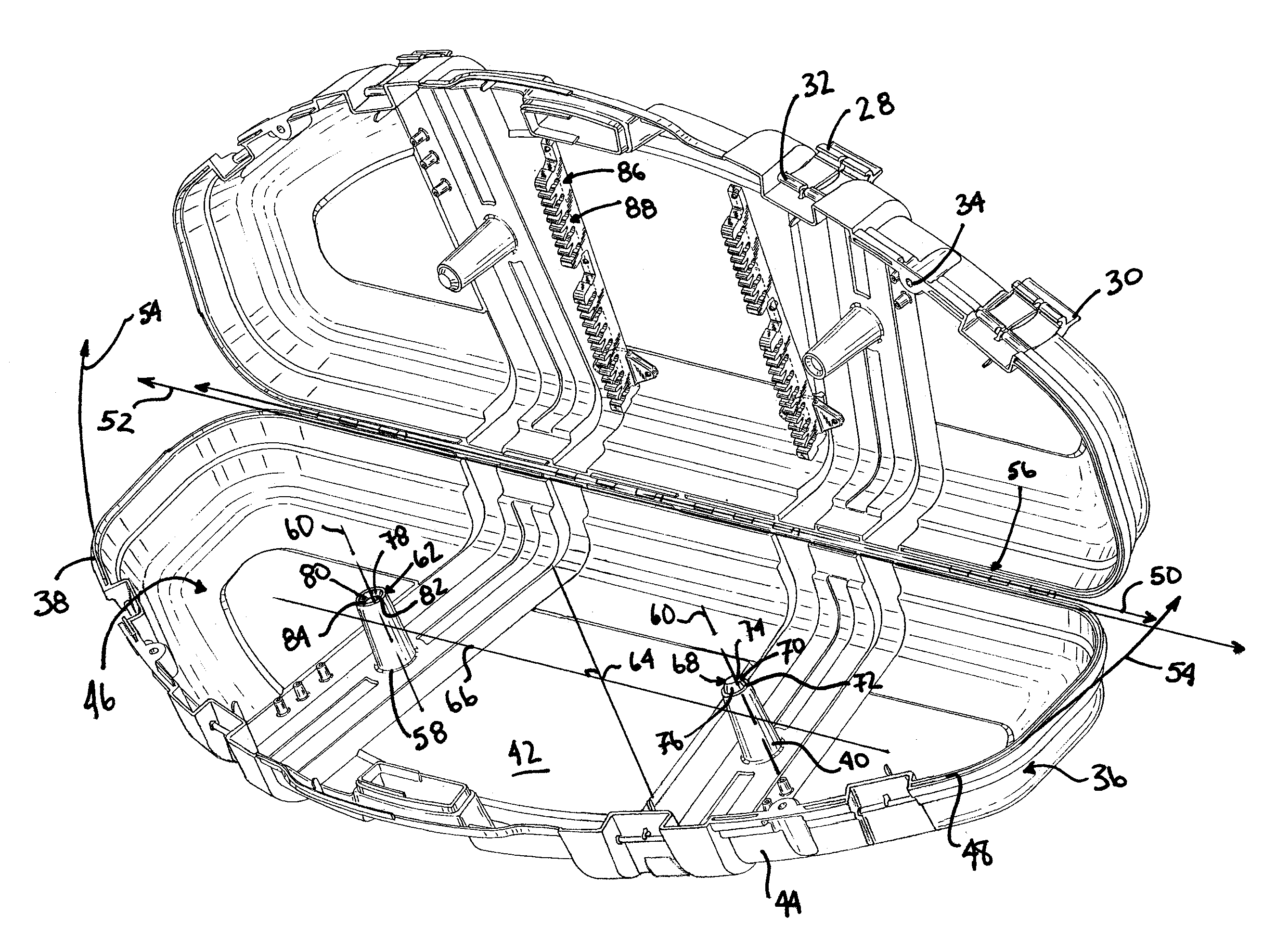

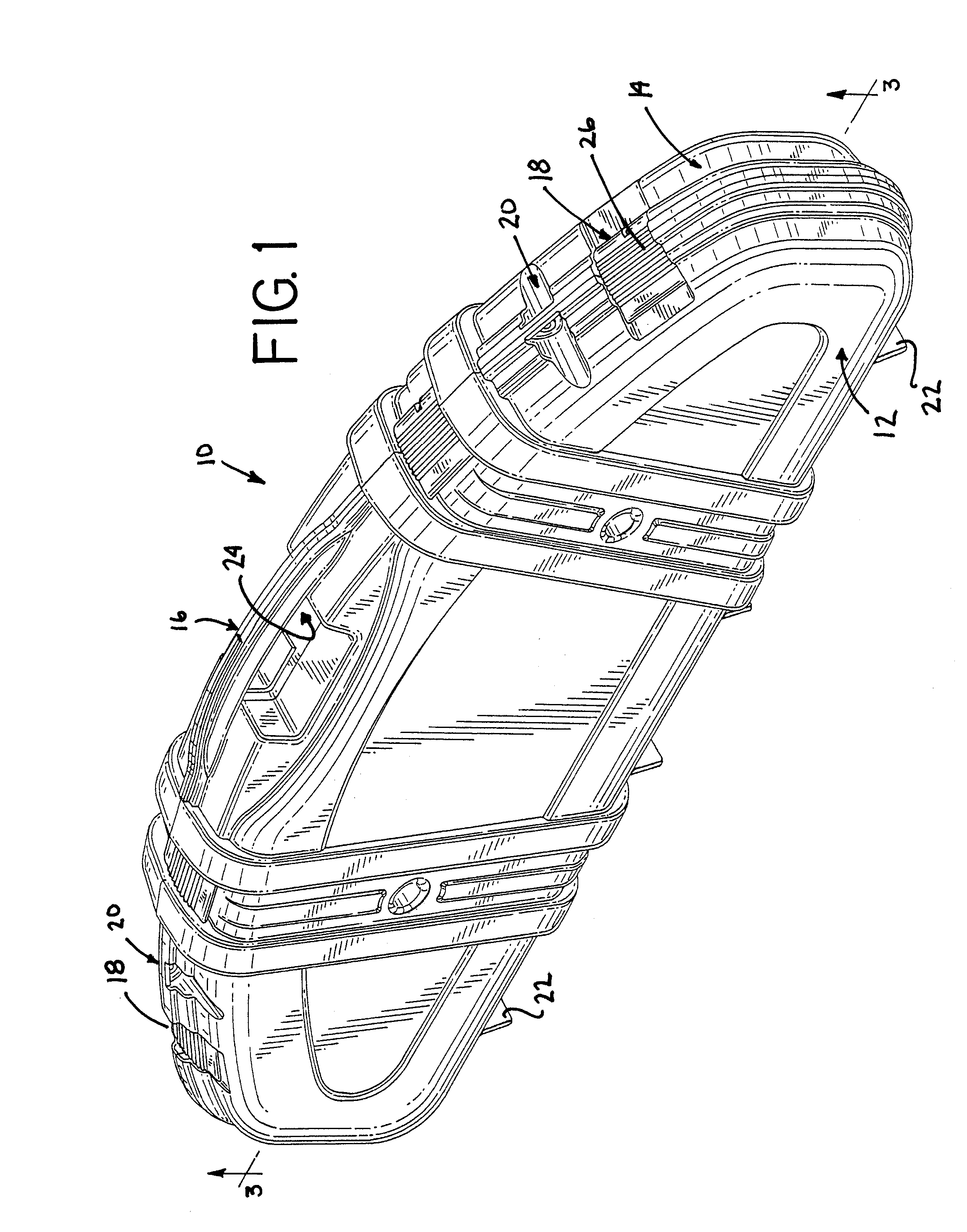

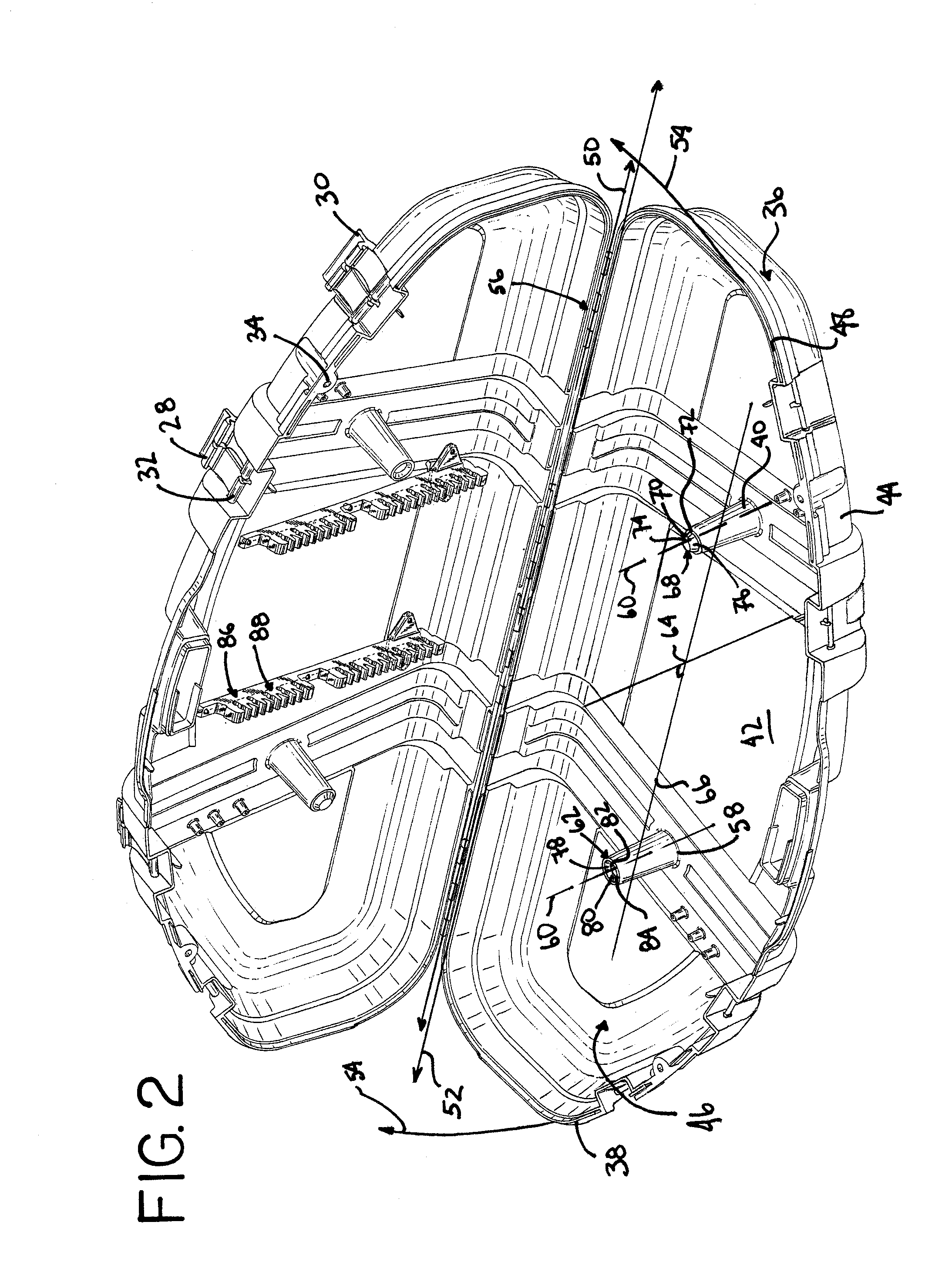

[0026] The present invention relates to a protective case for transporting and / or storing archery implements, preferably at least a bow and a plurality of arrows. Generally, the case 10 of the present invention shown in FIGS. 1-5, includes interengaging halves, a first half portion 12 and a second half portion 14 which are interconnected along a hinge line for movement between an open position, FIG. 2, and a closed position, FIGS. 1 and 3. As shown in FIG. 1, the case 10 also includes a handle 16, a plurality of latching devices 18, locking members 20, and a plurality of feet 22.

[0027] The handle 16 is formed by cooperation of the first half portion 12 and the second half portion 14. A passage 24 provided below the handle 16 for receiving the hand or fingers of an operator enables one to carry or move the case 10. Each latching device 18 in FIG. 2 includes an arm 26 and a catch 28. The arm 26 is movably secured to the case 10, and preferably to the second half portion 14. The prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com