Link-and-pin fixing structure for a crawler chain

a technology for crawler chains and fixing structures, which is applied in the direction of driving chains, couplings, manufacturing tools, etc., can solve the problems of pins being easily loose, starting or coming out, and linking chains interfering with outside obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

42. Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

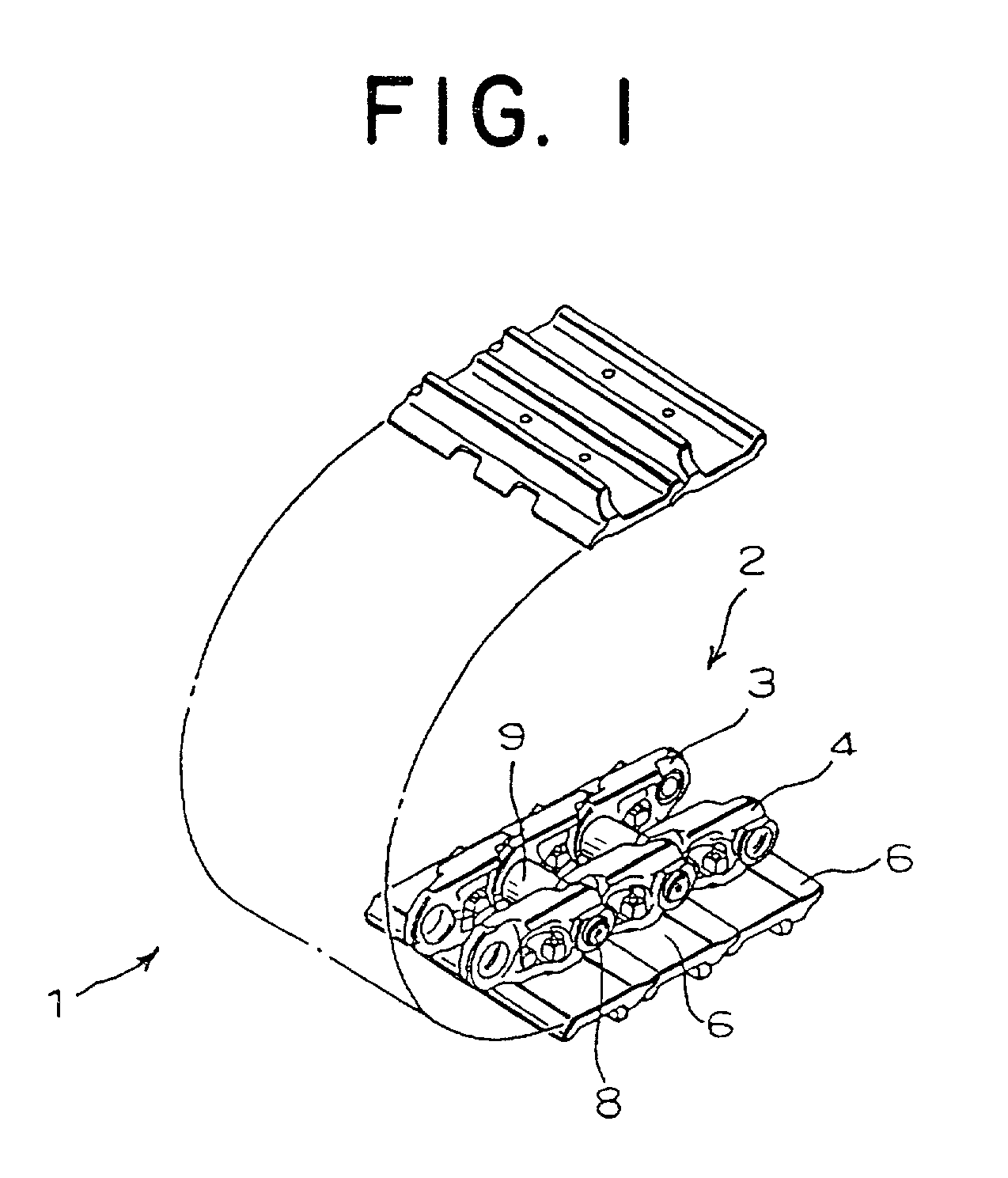

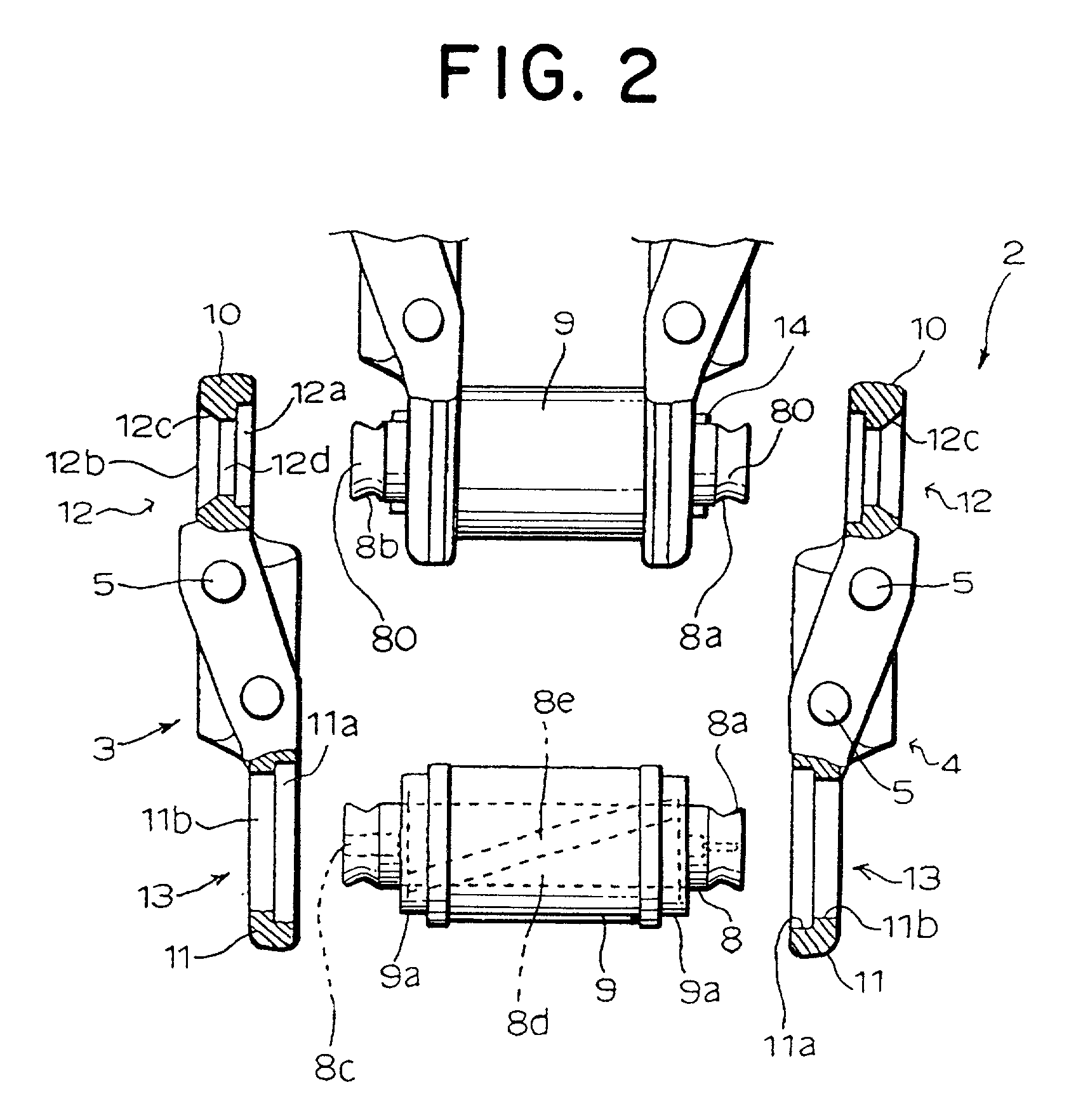

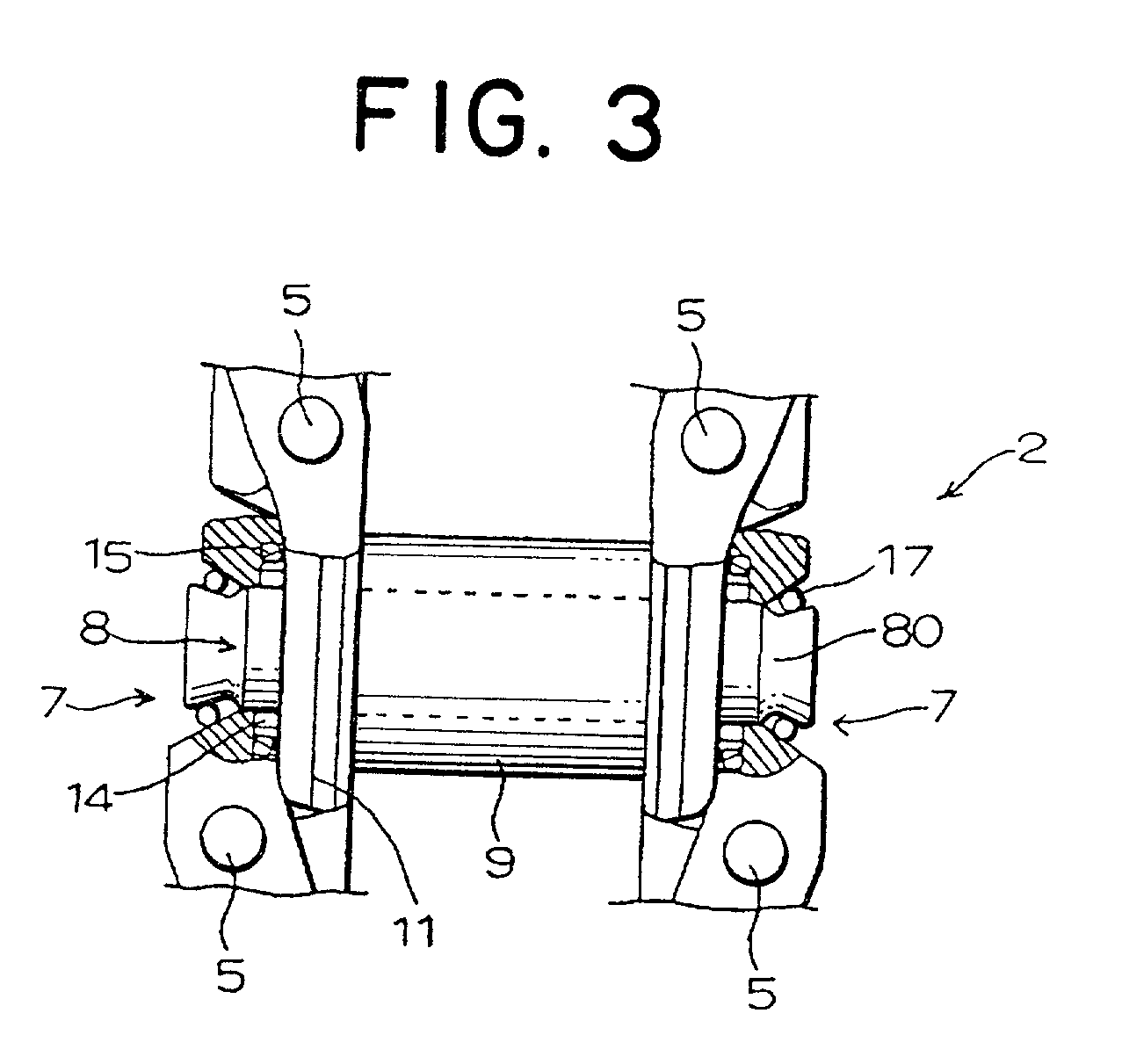

43. FIG. 1 is a structural view showing part of a link chain having a fixing structure of links and pins in the crawler chain of the present invention. FIG. 2 is a partially broken exploded view showing the link chain partially disassembled. FIG. 3 is a structural view showing a part of the link-and-pin-fixing structure, partly in cross section. FIG. 4 is a structural diagram showing contact conditions at the time when an elastic ring is fitted to the link and the pin

44. In FIG. 1, reference numeral 1 denotes a crawler chain of crawler-type vehicle for construction machine, transportation machine or the like. The crawler chain 1 is rotatably wound around traveling drive wheels (not shown) comprised of idler wheels disposed at a front part of the crawler-type vehicle, sprocket wheels disposed at a rear part thereof and track wheels disposed in a center part th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com