Novel turbodrill capable of achieving accurate positioning of stator and rotor

A technology of precise positioning and turbo drilling tools, which is applied in the direction of earthwork drilling, drilling equipment, and driving devices for drilling in boreholes, etc. It can solve the problems of low hydraulic performance, reduce compaction force, improve hydraulic performance, and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

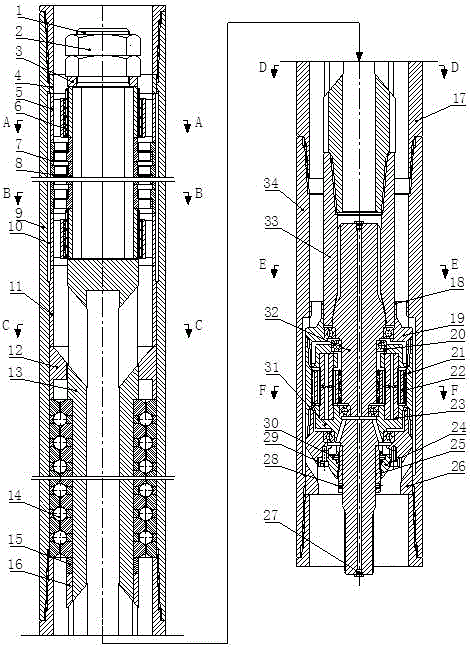

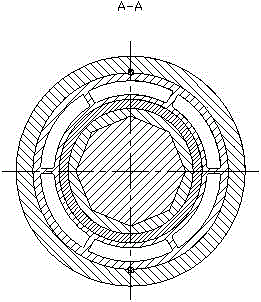

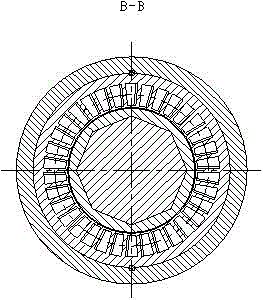

[0016] According to the drawings, the new type of turbodrill that can realize the precise positioning of the stator and rotor is mainly composed of screws 1, fastening nuts 2, adjustment rings 3, bearing sleeves 5, radial bearings 6, turbine stators 7, turbine rotors 8, Upper housing 9, flat key 10, adjusting ring 11, guide ring 12, turbine shaft 13, bearing group 14, intermediate housing 17, O-ring 18, guide sleeve 19, cylindrical roller bearing 20, internal gear 21. Planetary gear 22, planetary wheel shaft 23, sealing cover 24, gap sealing device 25, reducer housing 26, protection screw 27, cylindrical positioning pin 28, set screw 29, U-shaped sealing device 30, output shaft under the planetary wheel frame 31, sun gear shaft 32, spline sleeve 33 and lower casing 34 etc. are formed. It is characterized in that the blades of the turbine rotor 8 and the turbine stator 7 are installed in reverse, the turbine rotor 8 and the turbine stator 7 are fixedly installed on the turbine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com