Multilayered electrical flat conductor

An electrical connection and cable technology, applied in the field of cable connection, can solve problems such as electrical contact interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

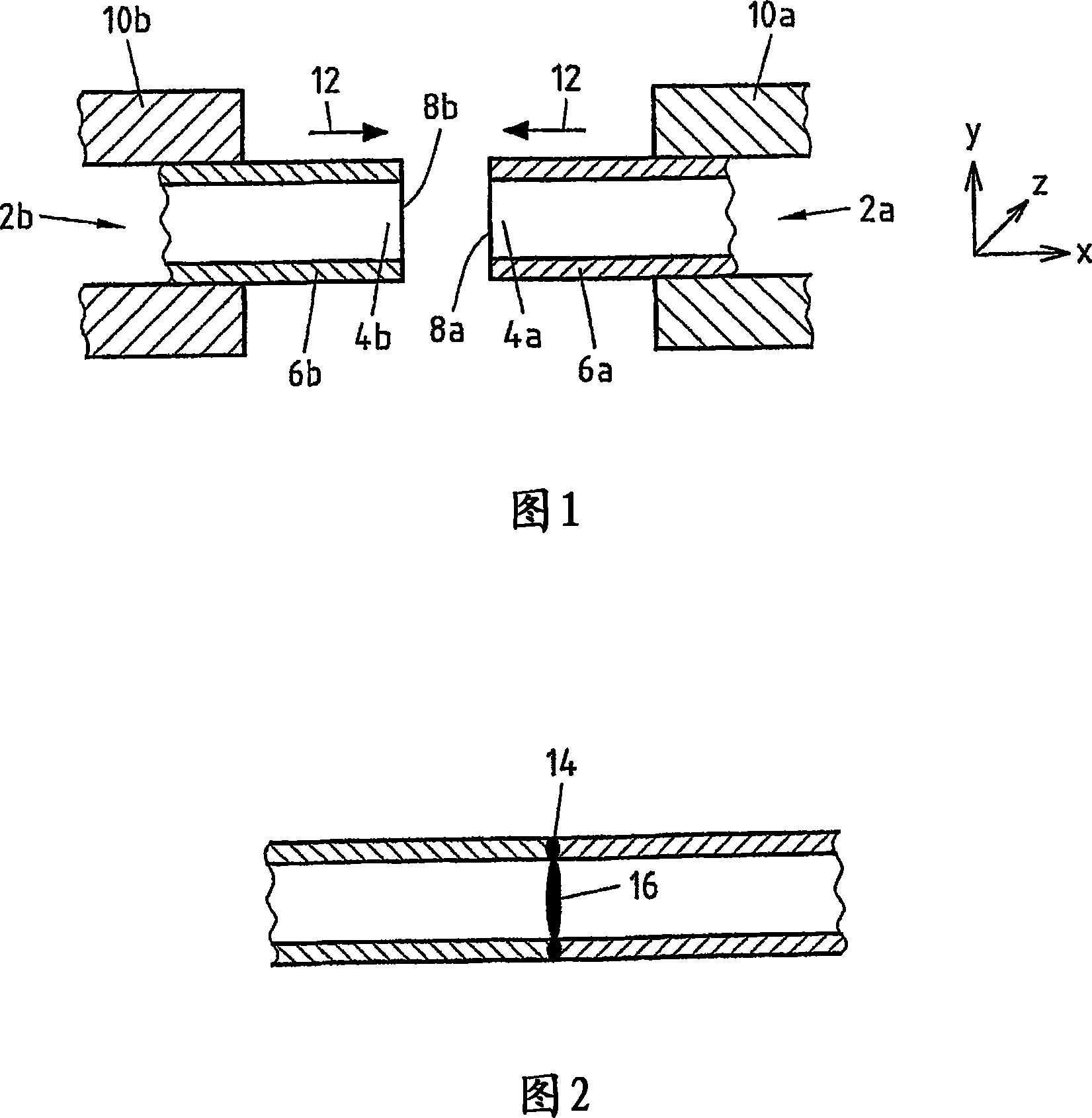

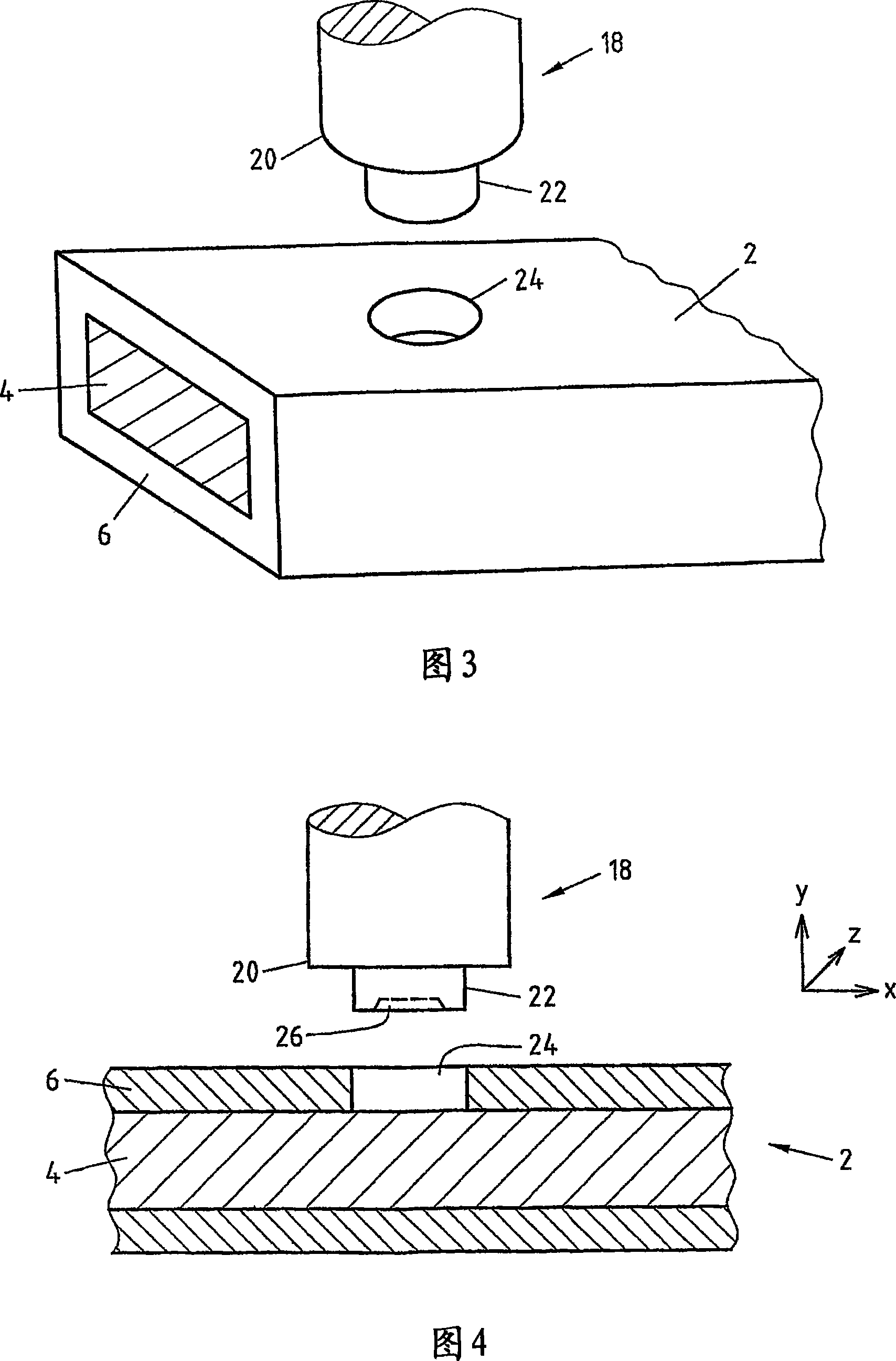

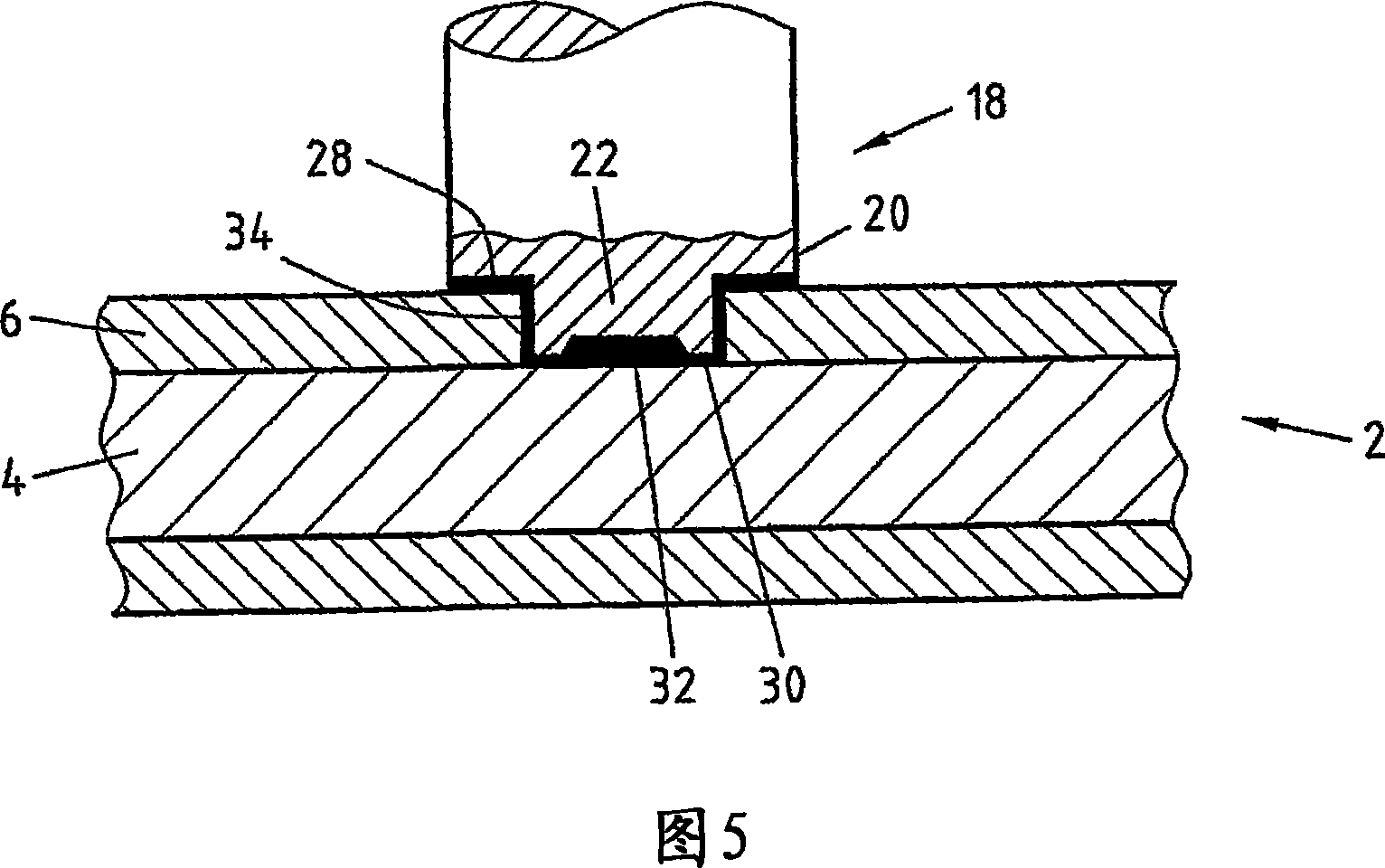

[0024] In order to realize the multi-track welding used according to the application, the workpieces to be joined must be clamped adjacent to each other on the joining surfaces in the welding tool. These joint surfaces press against each other.

[0025] For welding with the multi-track welding method, the joint surfaces are placed into oscillations, where the welding tool can be positioned in the xz-direction, yx-direction and / or yz-direction, depending on the clamping arrangement on the device oscillate in antiphase with each other. In this case the tool can oscillate with a fixed phase, phase shifted by 180°. Advantageously, the tools each oscillate only in one plane and apply the pressing force from a direction perpendicular to this plane.

[0026] With the multi-track welding method, the joining partners are materially joined to each other after less than a minute, especially after a few seconds, for example 5-7 seconds. The seam bulge is minimal because only relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com