Self-adjusting type thin film rolling mechanism

A self-adjusting, thin-film technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve problems such as film breakage and inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

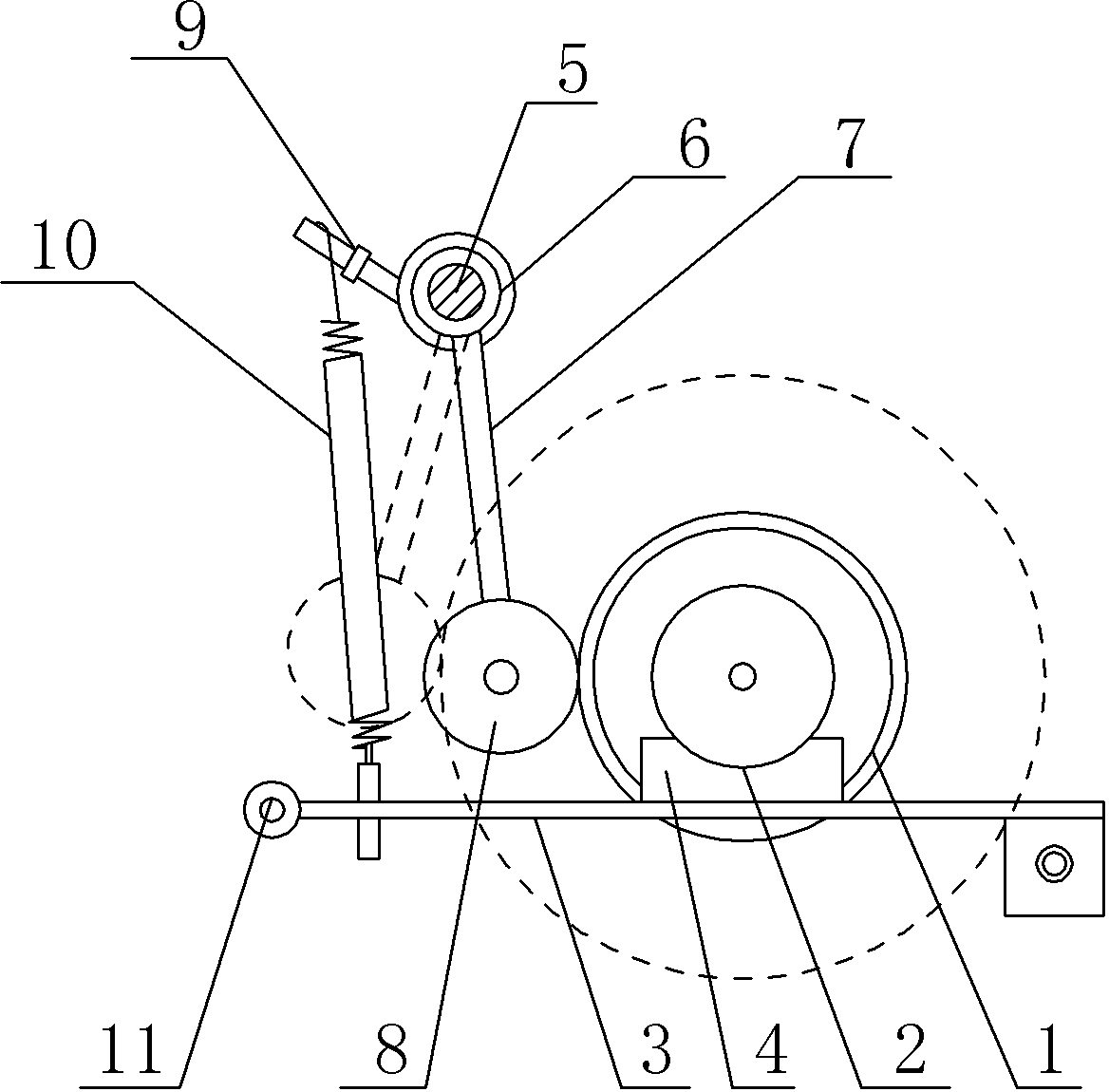

[0012] The reference signs in the drawings of the description include: 1-discharge roller, 2-friction wheel, 3-flat plate, 4-wheel yoke, 5-support shaft, 6-connecting disc, 7-pressure roller rod, 8-pressure roller , 9-screw rod, 10-spring rod, 11-counterweight.

[0013] The embodiment is basically as attached figure 1 Shown: the self-adjusting roll film mechanism, including the discharge roller 1 set on the frame and wound with the film, the friction wheel 2 is coaxially installed on the side of the discharge roller, and the friction wheel also rotates when the discharge roller rotates. The below of friction wheel is provided with flat plate 3, and the right end of this flat plate is hinged with frame, and counterweight 11 is installed on its left end.

[0014] A wheel yoke 4 is fixed at the position corresponding to the flat plate and the friction wheel. The top surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com